10 Game-Changing Industrial 3D Printers Transforming Manufacturing in 2024

Picture this—you’re designing a high-performance car part, and instead of waiting weeks for machining, you hit “print” and hold it in your hands hours later. Sounds like science fiction? Nope, that’s industrial 3D printing in 2024.

These aren’t your average desktop hobby machines. We’re talking about the powerhouses—the industrial 3D printers that are flipping the script in aerospace, automotive, healthcare, and manufacturing. Let’s break down the top 10 game-changers making waves this year.

What Makes a 3D Printer Industrial?

Think of an industrial 3D printer like a high-performance sports car. It’s built for speed, endurance, and precision. Here’s what sets them apart:

- Large build volumes (think furniture-sized parts)

- Advanced materials: carbon fiber, metal, PEEK, etc.

- Tight tolerances and high repeatability

- Integrated software for industrial workflows

- Production-ready: Can run 24/7 with minimal supervision

In short: they’re built to do the job, do it well, and do it again.

Why Are Industrial 3D Printers in High Demand?

Because they’re fast, versatile, and cost-effective. Here’s what the buzz is all about:

- 🚀 Faster Prototyping – Skip weeks of tooling and traditional mold-making.

- 🔧 Complex Designs – Print parts impossible to create otherwise.

- 🌱 Less Waste – Additive = efficient. Only the material you need.

- 💰 Lower Production Costs – Especially for short runs or custom parts.

It’s not just hype—it’s manufacturing magic in real life.

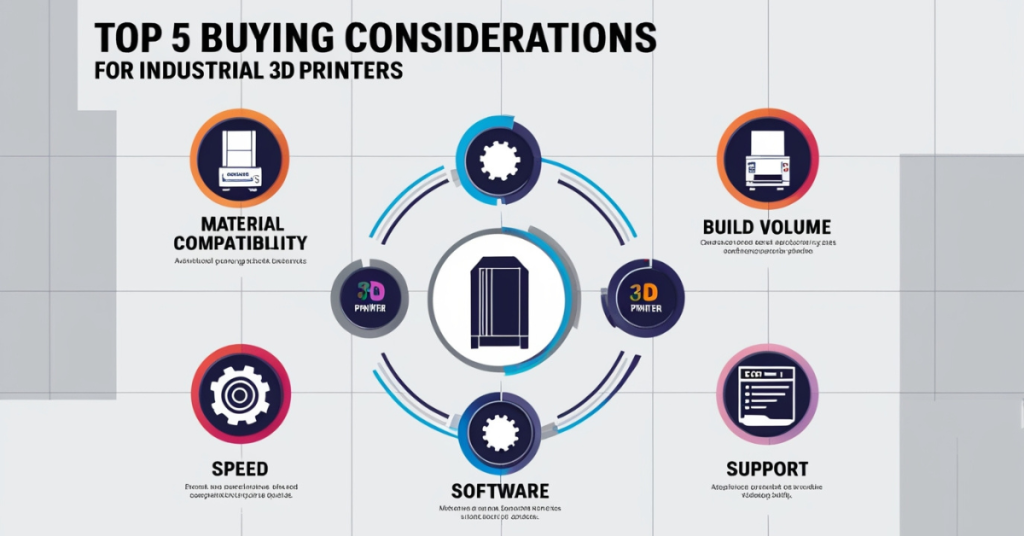

What Should You Look for in an Industrial 3D Printer?

Before you invest, ask yourself:

- What materials do you need? (metal, resin, thermoplastics)

- How big are your parts? (build volume matters)

- How fast do you need them? (production speed can be a dealbreaker)

- Is support and software important? (spoiler alert: yes, always)

Make sure the printer fits your workflow, not the other way around.

💥 Top 10 Industrial 3D Printers Transforming Manufacturing in 2024

Now, let’s get to the juicy part – the printers themselves. We’re talking about industrial behemoths that are changing the game. Ready to meet the stars of the show?

1 Markforged X7

- Material: Continuous carbon fiber, Onyx, fiberglass

- Build Volume: 330 × 270 × 200 mm

- Why It Rocks: Parts as strong as aluminum. Lightweight + tough = magic.

- Use Case: Automotive brackets, aerospace jigs

“It’s like having a mini factory in your office.”

2 Stratasys F900

- Material: ULTEM™, Nylon 12CF, PC, ABS

- Build Volume: 914 × 610 × 914 mm

- Why It Rocks: Aircraft-ready parts straight from the machine.

- Use Case: Aerospace, defense, large tools

“Built for factories. Period.”

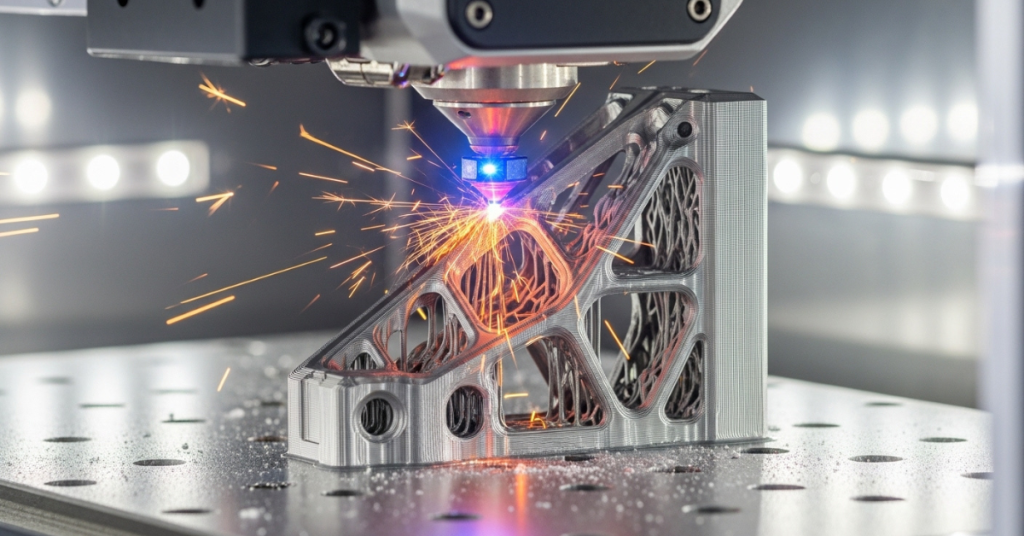

3 EOS M 290

- Material: Stainless steel, aluminum, titanium

- Build Volume: 250 × 250 × 325 mm

- Why It Rocks: Metal parts with high precision. DMLS at its best.

- Use Case: Medical implants, aerospace

“Prints metal parts that are production-grade.”

4 3D Systems ProX DMP 320

- Material: Titanium, aluminum, nickel alloys

- Build Volume: 275 × 275 × 420 mm

- Why It Rocks: Built for extreme accuracy in metal printing.

- Use Case: Energy, dental, aerospace

“Surgical precision for critical components.”

5 Desktop Metal Studio System 2

- Material: Tool steel, stainless steel, copper

- Build Volume: 300 × 200 × 200 mm

- Why It Rocks: No hazardous lasers. Office-safe metal printing.

- Use Case: Tooling, prototypes

“Plug-and-play metal printing.”

6 HP Jet Fusion 5200 Series

- Material: PA12, PA11, TPU

- Build Volume: 380 × 284 × 380 mm

- Why It Rocks: Blazing speed + functional parts.

- Use Case: Production-ready consumer products

“Batch production at warp speed.”

7 Raise3D Pro3 Plus

- Material: PLA, ABS, ASA, PETG, PC, Carbon Fiber

- Build Volume: 300 × 300 × 605 mm

- Why It Rocks: Dual extrusion. Auto-bed leveling. Industrial on a budget.

- Use Case: Prototyping, short-run manufacturing

“The gateway drug to industrial 3D printing.”

8 EnvisionTEC Xtreme 8K

- Material: Photopolymers (resin)

- Build Volume: 450 × 371 × 399 mm

- Why It Rocks: High-res, large-scale resin prints.

- Use Case: Dentistry, jewelry, medical

“Big prints with tiny details.”

9 Formlabs Form 4B

- Material: Engineering resins, bio-compatible materials

- Build Volume: 200 × 125 × 210 mm

- Why It Rocks: Desktop-sized but lab-ready.

- Use Case: Healthcare, prototyping

“The little printer that could (and does).”

10 Voxeljet VX4000

- Material: Sand, PMMA

- Build Volume: 4000 × 2000 × 1000 mm

- Why It Rocks: Largest 3D printer for sand casting molds.

- Use Case: Foundries, automotive, construction

“When size really does matter.”

Conclusion: The Future of Manufacturing Is Already Here

Whether you’re prototyping a new concept or scaling full-blown production, industrial 3D printers are no longer optional—they’re essential. From compact carbon-fiber champions to skyscraper-sized sand casters, there’s a machine for every need and budget.

If you haven’t jumped on the industrial 3D printing train yet, 2024 might just be the perfect time. It’s not just about staying ahead—it’s about not getting left behind.

❓ FAQs

- What is the most popular industrial 3D printer brand?

Stratasys and Markforged dominate the market, but HP, EOS, and Desktop Metal are serious contenders depending on your needs. - Can industrial 3D printers print metal?

Absolutely. Machines like the EOS M 290 and ProX DMP 320 specialize in high-quality metal printing for aerospace and healthcare. - Are industrial 3D printers worth the investment?

Yes—if you need fast prototyping, custom parts, or low-volume production. They often pay for themselves through efficiency and reduced tooling costs. - What materials do industrial 3D printers use?

Everything from carbon fiber and nylon to titanium, ceramics, and engineering resins. - Can small businesses use industrial 3D printers?

Definitely! Options like the Raise3D Pro3 Plus and Formlabs Form 4 make industrial-grade performance accessible for startups and studios.