Top 10 Thermoforming Machines for 3D Printing: The Best Options for Molding Printed Parts

Hey there, fellow 3D printing enthusiasts! Are you ready to take your creations to the next level? Well, buckle up because we’re about to dive into the exciting world of thermoforming machines for 3D printing. Trust me, this is going to be a game-changer for your projects!

What’s the Big Deal with Thermoforming?

Before we jump into our top picks, let’s chat about what thermoforming actually is. You know how superheroes have secret weapons? Well, thermoforming is like the secret weapon of 3D printing!

The Magic Behind the Mold

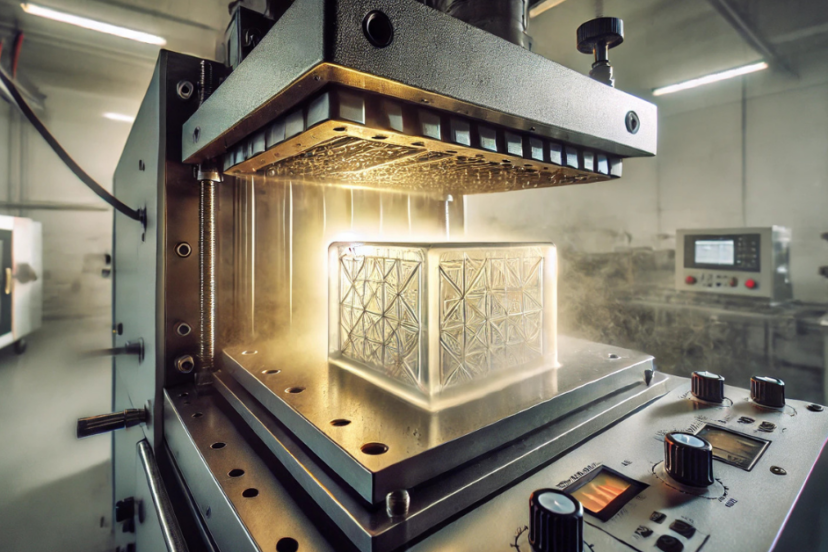

Imagine you could take your 3D printed part and give it a smooth, professional finish in minutes. That’s exactly what thermoforming does! It’s a process where we heat up a plastic sheet until it’s nice and pliable, then stretch it over your 3D printed mold. Once it cools down, voila! You’ve got a perfectly formed plastic part that looks like it came straight out of a factory.

Why Should You Care About Thermoforming for 3D Printed Parts?

Now, you might be thinking, “Why bother with thermoforming when I’ve got my trusty 3D printer?” Great question! Let me tell you why this combo is like peanut butter and jelly – simply meant to be together.

Smooth Operator

First off, thermoforming can give your 3D printed parts a smooth, professional finish that’s hard to achieve with printing alone. It’s like giving your creation a fancy makeover!

Speedy Gonzales of Production

Want to make multiple copies of your part quickly? Thermoforming is your new best friend. Once you’ve got your 3D printed mold, you can churn out copies faster than you can say “layer height.”

Material Madness

With thermoforming, you can use a wide range of plastics that might not be suitable for 3D printing. It’s like opening up a whole new world of material possibilities!

The Cream of the Crop: Top 10 Thermoforming Machines

Alright, let’s get to the good stuff! Here are the top 10 thermoforming machines that’ll make your 3D printing projects shine:

1. Formech 508FS

This bad boy is like the Swiss Army knife of thermoforming machines. It’s versatile, user-friendly, and perfect for both beginners and pros.

2. Mayku FormBox

Compact and affordable, the Mayku FormBox is the perfect sidekick for your desktop 3D printer. It’s like having a mini-factory right on your desk!

3. Vaquform Desktop Vacuum Former

With its digital controls and smart heating system, the Vaquform is bringing thermoforming into the 21st century. It’s so smart, it might just do your taxes too (okay, maybe not, but it’s still pretty cool).

4. EZFORM SV1217

The EZFORM SV1217 is a workhorse that can handle larger projects with ease. It’s like the bodybuilder of thermoforming machines – strong and reliable.

5. Centroform EZFORM Table Top

Don’t let its size fool you – this compact machine packs a punch. It’s perfect for small workshops or if you’re tight on space.

6. Formech 686

The Formech 686 is a step up in terms of size and capability. It’s ideal for those looking to scale up their thermoforming game.

7. Ridat Thermoforming Machine

Known for its durability and precision, the Ridat machine is a favorite among professionals. It’s like the wise old sage of thermoforming machines.

8. Illig UA 100g

This German-engineered machine is all about efficiency and quality. It’s like the luxury sports car of thermoforming – sleek, powerful, and precise.

9. Polyform Machinery Vacuum Former

With its user-friendly interface and robust construction, the Polyform machine is great for both newbies and seasoned pros alike.

10. Bel-O-Vac Vacuum Forming Machine

Rounding out our list is the Bel-O-Vac, known for its reliability and consistent performance. It’s like the dependable friend who’s always there when you need them.

Choosing Your Perfect Match: Factors to Consider

Now that we’ve got our top 10, how do you pick the right one for you? It’s like choosing a dance partner – you need to find the one that matches your style and needs.

Size Matters

Think about the size of the parts you’ll be forming. You don’t want to end up with a machine that’s too small for your big ideas!

Budget Buddy

Let’s face it, we can’t all splurge on the fanciest machine out there. Consider your budget and remember, sometimes the mid-range options offer the best bang for your buck.

User-Friendliness

Are you a thermoforming newbie or a seasoned pro? Choose a machine that matches your skill level. You don’t want to be overwhelmed, but you also don’t want to be underwhelmed.

Material Compatibility

Make sure the machine can handle the types of plastics you plan to use. It’s like making sure your favorite shoes fit before buying them!

Thermoforming 101: How to Use Your New Machine

Got your shiny new thermoforming machine? Great! Let’s walk through how to use it. Don’t worry, it’s not rocket science (although it’s pretty close to magic).

Step 1: Prep Your Mold

First things first, get your 3D printed mold ready. Make sure it’s clean and free from any imperfections.

Step 2: Heat It Up

Place your plastic sheet in the machine and let it heat up. It’s like warming up before a workout – crucial for good results!

Step 3: Form and Cool

Once the plastic is nice and pliable, lower it onto your mold and let the vacuum do its thing. Then, give it time to cool down and set.

Step 4: Trim and Finish

Remove your newly formed part and trim off any excess plastic. Voila! You’ve just thermoformed your first piece.

Pro Tips for Thermoforming Success

Want to take your thermoforming game to the next level? Here are some tips from the pros:

- Experiment with different plastics: Each type has its own quirks and benefits.

- Keep your mold cool: A cool mold helps the plastic set faster and more accurately.

- Mind the details: Small details can be tricky, so design your molds accordingly.

- Practice makes perfect: Don’t get discouraged if your first attempts aren’t perfect. Keep at it!

Wrapping It Up: The Future is Formed

And there you have it, folks! We’ve journeyed through the world of thermoforming machines for 3D printing. From understanding the basics to picking the perfect machine, you’re now armed with the knowledge to take your 3D printing projects to new heights.

Remember, thermoforming isn’t just about making pretty parts – it’s about expanding what’s possible with your 3D printer. It’s about bringing your ideas to life in new and exciting ways. So go forth, experiment, and create amazing things!

FAQs

- Can I use any plastic for thermoforming?

Not all plastics are created equal when it comes to thermoforming. Some common options include PETG, ABS, and HIPS, but always check your machine’s specifications. - How thick can the plastic sheet be for thermoforming?

This depends on your machine’s capabilities, but most desktop thermoformers can handle sheets up to 1-2mm thick. - Is thermoforming environmentally friendly?

It can be! Many thermoforming plastics are recyclable, and the process produces minimal waste compared to other manufacturing methods. - Can I thermoform food-safe products?

Yes, but you need to use food-safe plastics and ensure your entire process is hygienic. Always check local regulations for food-safe manufacturing. - How long does a typical thermoforming process take?

The actual forming process is quick, often taking just a few minutes. However, cooling time can vary depending on the size and thickness of your part.