Is There a Specific Technique to Vacuum-Sealing Filament to Avoid Damage?

Vacuum-sealing is a highly effective way to protect 3D filament from moisture and environmental contaminants, but improper sealing can lead to damage or compromised filament quality. To ensure that your filament remains in excellent condition during storage, it’s important to use the correct technique. Here’s how to properly vacuum-seal filament to avoid damage:

1. Use the Right Type of Vacuum-Sealing Bags

- What It Means: Not all vacuum-sealing bags are the same, and the material of the bag plays a significant role in protecting filament. Some bags are too thin and prone to puncturing, while others are designed to be more durable.

- Why It Matters for Filament Storage: Using high-quality, heavy-duty vacuum-sealing bags ensures that your filament is sealed securely and won’t be easily damaged by pressure or moisture.

- How to Do It: Use multi-layer, moisture-resistant bags that are specifically designed for long-term storage. Thick, durable bags will provide better protection against physical damage and maintain their integrity over time.

- Benefit: Proper bags reduce the risk of punctures or rips that could compromise the vacuum seal and expose the filament to moisture.

2. Don’t Over-Compress the Filament

- What It Means: Over-compressing the filament during the vacuum-sealing process can cause deformation, brittleness, or spool distortion.

- Why It Matters for Filament Storage: Filament is often wound tightly on a spool, and applying too much vacuum pressure can result in the spool being crushed or deformed. This deformation may make it difficult to feed filament into the printer without tangling or breaking.

- How to Do It: When vacuum-sealing, make sure there is enough space in the bag for the filament spool to maintain its shape. Avoid over-tightening the vacuum seal. Some vacuum sealers have an option to adjust the seal strength—set it to a moderate pressure, just enough to remove air but not excessively compress the spool.

- Benefit: Proper pressure ensures that the filament remains intact, easy to use, and ready for printing without any issues related to deformation or tangling.

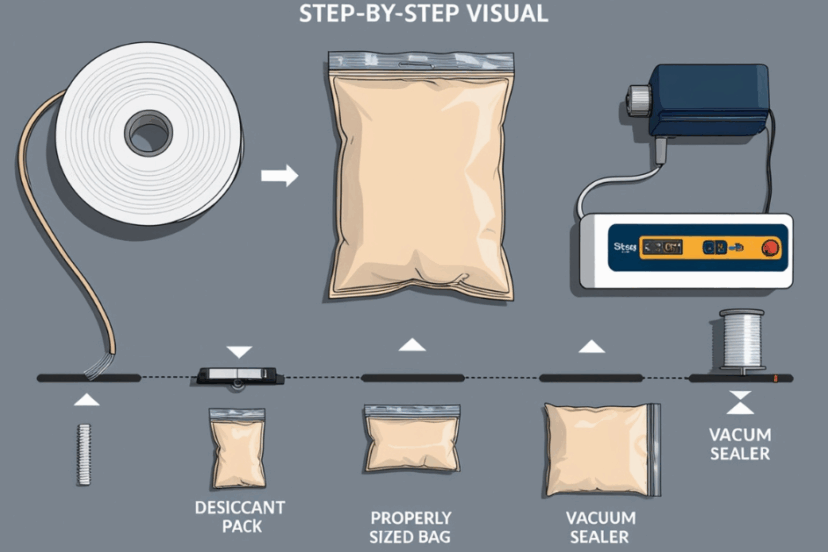

3. Ensure Proper Bag Size

- What It Means: The size of the vacuum-sealing bag is important. If the bag is too small, it will be difficult to seal the filament properly without cramming it into the bag, causing pressure damage. Conversely, a bag that is too large will result in ineffective vacuuming as the air cannot be properly removed from the excess space.

- Why It Matters for Filament Storage: If the bag is too tight, it can cause damage to the filament. If it’s too loose, the seal won’t be as effective, and the filament will be exposed to air and moisture.

- How to Do It: Choose a bag size that allows the filament spool to fit comfortably without too much space around it. If you’re storing a single spool, use a smaller bag for better vacuum efficiency. If you’re storing multiple spools, use a larger bag but ensure it’s not overly spacious.

- Benefit: The right bag size allows for a tight, secure vacuum seal without causing unnecessary pressure on the filament spool.

4. Avoid Direct Contact with the Vacuum Sealer’s Sealing Strip

- What It Means: The vacuum sealer’s heating strip is used to seal the bag, and if the filament spool touches this area directly, it could be damaged by excessive heat.

- Why It Matters for Filament Storage: Filament, particularly Nylon and TPU, can be sensitive to heat. Direct contact with the heating strip can cause the filament to become soft or deformed, affecting its printability.

- How to Do It: Make sure the filament spool is positioned well within the bag, with enough space between the spool and the sealing strip. The spool should not be touching the area where the vacuum sealer applies heat.

- Benefit: Preventing contact with the heat strip ensures that the filament remains undamaged and ready for use when you open the vacuum-sealed bag.

5. Seal the Bag Properly

- What It Means: The quality of the vacuum seal itself is crucial. If the vacuum sealer does not form a tight, airtight seal, moisture and air can enter, and the filament will not be fully protected.

- Why It Matters for Filament Storage: A poor seal will allow moisture and dust to penetrate, leading to filament degradation over time. A strong, airtight seal ensures that the filament remains protected from the environment.

- How to Do It: After vacuuming out the air, use the sealer’s seal function to make sure the bag is securely closed. Some models offer an option to seal multiple times to ensure a stronger, more reliable seal. Always inspect the seal for any gaps or weak spots before storing.

- Benefit: A reliable, airtight seal maximizes the moisture protection and preserves the quality of the filament over the long term.

6. Add Desiccants Inside the Bag

- What It Means: Desiccants, such as silica gel packets, are used to absorb any residual moisture inside the bag. Even if the vacuum-sealer does an excellent job removing air, there can still be some moisture trapped inside the bag.

- Why It Matters for Filament Storage: Moisture is one of the biggest enemies of 3D filament. Without desiccants, filament can absorb the moisture inside the bag, leading to issues like bubbling, stringing, and poor adhesion when printing.

- How to Do It: Place one or two desiccant packs inside the vacuum-sealed bag before sealing. Silica gel is a common desiccant, and it’s often available in small packets. Be sure to choose desiccants that are appropriate for the size of the bag and the moisture sensitivity of the filament.

- Benefit: Desiccants help maintain a dry environment inside the bag, ensuring that your filament remains moisture-free even if the bag is opened occasionally.

7. Check for Punctures or Leaks

- What It Means: After sealing the bag, it’s essential to inspect it for any punctures or leaks that may allow air or moisture to get inside. Even small holes or weak spots in the seal can compromise the vacuum environment.

- Why It Matters for Filament Storage: If there are punctures or leaks, the vacuum bag will not provide the moisture protection that is crucial for filament preservation.

- How to Do It: After sealing the bag, check for leaks by gently pressing on the bag and watching for any air bubbles or gaps. You can also use a leak test by leaving the sealed bag for a few hours to check if air re-enters.

- Benefit: Ensuring the bag is completely sealed without leaks guarantees that your filament is protected from exposure to air and moisture.

8. Store Vacuum-Sealed Bags Properly

- What It Means: The way you store your vacuum-sealed bags after sealing them plays a role in keeping your filament safe.

- Why It Matters for Filament Storage: Storing bags improperly can cause physical damage to the filament spool, such as crushing or bending.

- How to Do It: Store vacuum-sealed bags upright or in a place where they won’t be crushed or subjected to excessive pressure. Ideally, keep them in a cool, dry, and dark environment, as heat and UV exposure can degrade filament.

- Benefit: Proper storage ensures that the vacuum-sealed bag stays intact, keeping your filament in its best condition.

Summary of Techniques for Vacuum-Sealing Filament Without Damage:

- Use high-quality, durable bags that provide a strong seal and prevent punctures.

- Avoid over-compressing the filament during the sealing process to prevent deformation.

- Choose the correct bag size to ensure the filament spool is properly secured without excess space.

- Ensure the spool does not touch the heat strip to avoid heat damage.

- Seal the bag properly to create an airtight, reliable seal.

- Add desiccants to absorb residual moisture inside the bag.

- Check for leaks after sealing to ensure the bag remains airtight.

- Store vacuum-sealed bags properly in a cool, dry, and dark place.

Conclusion:

Vacuum-sealing filament is an excellent way to preserve its quality and protect it from moisture and contaminants. By following the proper techniques—such as using durable bags, avoiding over-compression, and adding desiccants—you can ensure that your filament remains in excellent condition for long-term storage. With the right approach, vacuum-sealing can effectively extend the shelf life of your filament and keep it ready for high-quality prints when you need it.