How to create a filament rotation system for efficient use and storage?

1. Stop Forgetting What You Have

If you’ve ever ordered a new spool…

…only to find the exact same color hiding in the back of your bin…

you need a filament rotation system.

Let’s fix the chaos and show you how to organize, track, and rotate filament like a pro.

2. What Is a Filament Rotation System?

It’s a simple method that ensures you:

- Use up older spools before newer ones

- Avoid moisture-related print failures

- Keep track of opened, used, and unused filament

- Reduce filament waste and reprinting time

Just like grocery stores rotate food inventory, you can do the same with filament.

3. Why You Need One (Even as a Hobbyist)

- Keep your prints consistent

- Know what’s still good to use

- Avoid drying spools over and over again

- Stop wasting money on forgotten filament

- Save time searching for the “right” color or material

4. The Problem With Random Spool Grabbing

Without rotation:

- Older spools dry out, absorb moisture, and become brittle

- Half-used colors get forgotten

- You keep re-drying the same filament

- You run out of filament mid-print because you misjudged weight

Disorder kills print flow—and motivation.

5. First In, First Out (FIFO): The Golden Rule

The FIFO rule is simple:

Use the first spool you opened before opening a new one of the same type.

This prevents old filament from sitting unused, losing quality, or requiring extra drying later.

6. Step 1: Label Every Spool You Open

Every spool needs a label with:

- Material (PLA, PETG, etc.)

- Brand/Color

- Opened date

- Last dried date (if applicable)

- Optional: Weight remaining

Use masking tape, label makers, or printable stickers. Stick the label on the spool or storage bag.

7. Step 2: Sort Spools by Activity Status

Create 3 categories:

| Status | Meaning |

|---|---|

| Active | Currently in use |

| Open – Backup | Opened but not in rotation |

| Unopened | Factory sealed, not yet used |

Keep each group in separate bins or shelves so you know where to grab from.

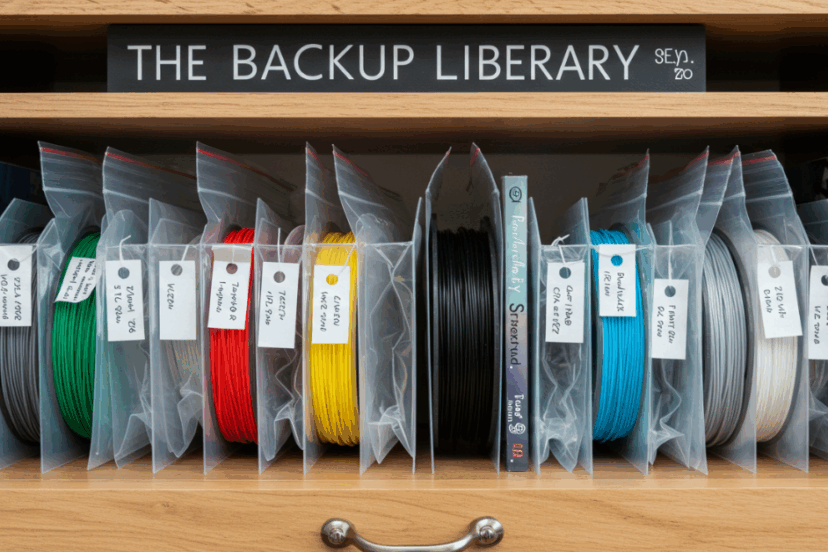

8. Step 3: Create Dedicated Storage Zones

- Bin A: Actively used filaments

- Bin B: Opened but inactive (awaiting use)

- Bin C: Unopened vacuum-sealed spools

- Bin D: Moisture-sensitive materials (Nylon, TPU, etc.)

This gives you a physical “workflow” without needing to think every time.

9. Step 4: Use Color Codes or Tags

Color-coded stickers, zip ties, or tags make things easier at a glance:

- 🔵 Blue = Dry and ready

- 🟡 Yellow = Open but needs drying soon

- 🔴 Red = Needs drying ASAP or nearly empty

It’s visual, quick, and prevents surprises during a print job.

10. Step 5: Track Drying & Usage Dates

Write down:

- When the spool was last dried

- How long it’s been sitting

- Estimated remaining filament weight

Apps like Filamentory or spreadsheets in Google Sheets work great for this.

11. Step 6: Prioritize Use Based on Age or Sensitivity

Print from:

- Oldest opened spool of the correct type

- Most moisture-sensitive materials first

- Colors you want to use up and retire

Don’t save “just a little bit” of that rare color—use it before it dries out.

12. Best Containers for a Rotation System

| Storage Tool | Best For | Notes |

|---|---|---|

| Dry boxes | Active rotation | Print directly from box |

| Stackable bins | Opened backups | Add labels to each bin |

| Vacuum bags | Long-term backup | Include labels inside bag |

| File racks | Easy spool access | Great for vertical rotation setup |

Bonus: Add a whiteboard or chalkboard for quick notes near your filament zone.

13. Creating a Digital Filament Inventory

Build a simple table with columns like:

- Spool ID

- Filament type

- Brand/color

- Opened date

- Last dried date

- Status (Active, Backup, Unopened)

- Notes (dry temp, print temp, use history)

You can even link a QR code to each spool if you’re managing 20+ spools.

14. Bonus: Include Weight Estimates for Better Planning

Use a kitchen scale to weigh each spool:

- Weigh the empty spool once and write it down

- Weigh the loaded spool

- Subtract to estimate how much filament is left (in grams)

Track this digitally or mark it on the label—super helpful for planning large prints.

15. Final Thoughts: A Little Prep Goes a Long Way

A solid filament rotation system is like having a smart inventory manager for your print station.

✅ Less waste

✅ Fewer surprises

✅ No forgotten spools

✅ Smooth project flow

It takes just a little effort up front—but you’ll save hours of guesswork down the line.

❓FAQs

- Do I really need this if I only have a few spools?

Even with 3–5 spools, it helps. You’ll always know what’s dry, what’s open, and what’s ready. - Can I mix different filament types in the same rotation system?

Yes—but keep them physically separated and clearly labeled to avoid printing mistakes. - How often should I update spool status?

Every time you open, dry, or finish a spool. Takes 30 seconds but saves a print. - Is a spreadsheet better than physical tags?

Use both! Labels help during printing, and spreadsheets help you plan and track over time. - What if I lose track of a spool’s status?

Dry it again, label it clearly, and move it to active rotation to avoid uncertainty.