Top 10 Metal 3D Printers of 2024: The Best Machines for Precision and Strength

What if you could print solid metal parts with the same ease as plastic? Well, you can! Metal 3D printing is revolutionizing manufacturing, prototyping, and production, making it faster and more cost-effective than traditional methods.

Gone are the days when metal 3D printers were exclusive to multi-million-dollar corporations. Today, they’re more accessible, precise, and efficient than ever. Whether you’re an engineer, manufacturer, or small business owner, investing in the right metal 3D printer can take your production to the next level.

So, which machines lead the pack in 2024? Let’s dive into the top 10 metal 3D printers that offer the best precision, strength, and innovation.

What Are Metal 3D Printers?

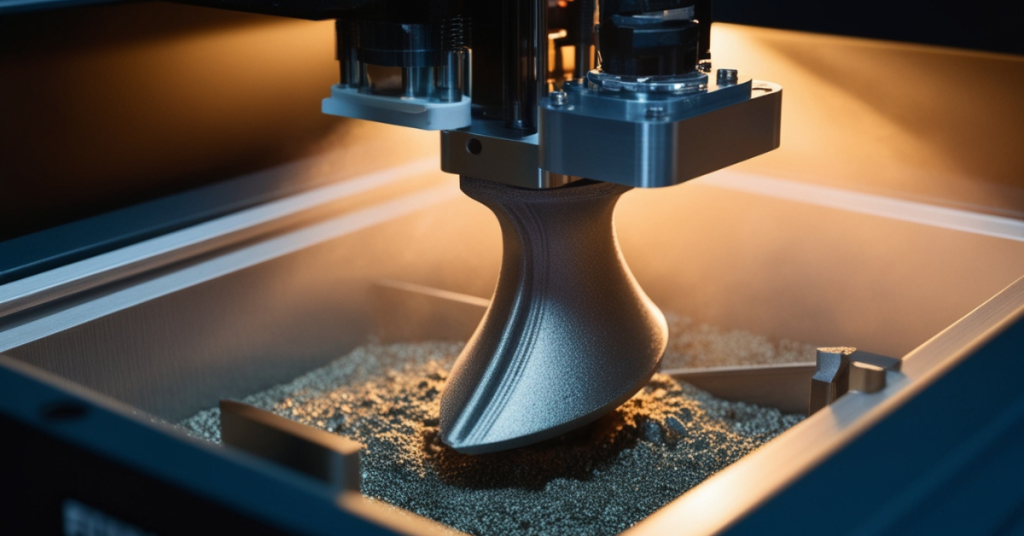

A metal 3D printer uses advanced additive manufacturing techniques to create solid metal parts layer by layer. Unlike traditional CNC machining, which cuts material away, 3D printing builds objects from the ground up, reducing waste and enabling complex geometries.

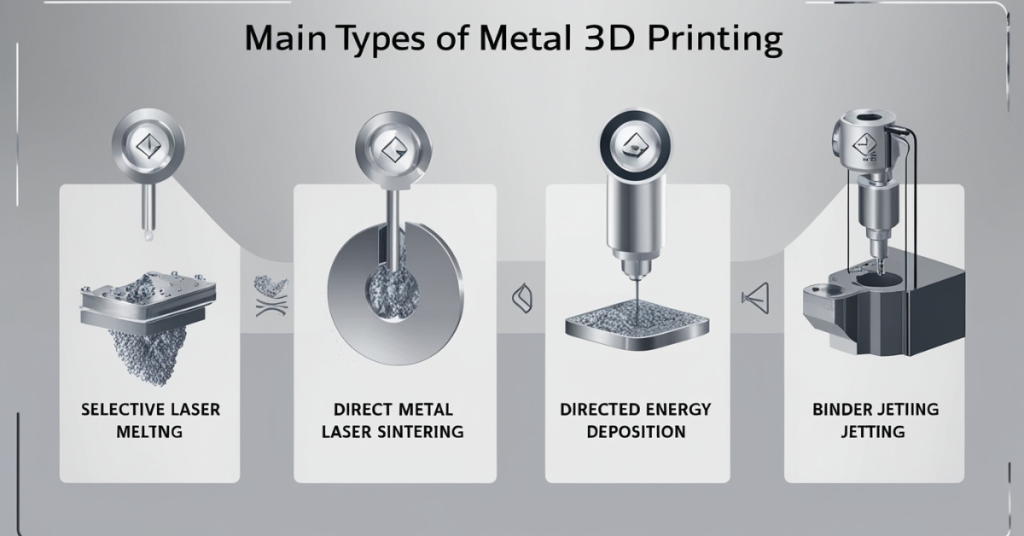

Types of Metal 3D Printing Technologies:

- Selective Laser Melting (SLM) & Direct Metal Laser Sintering (DMLS) – Uses lasers to fuse metal powder.

- Binder Jetting – Uses a liquid binder to bond metal powder, followed by sintering.

- Directed Energy Deposition (DED) – Uses a laser or electron beam to melt metal powder or wire.

- Bound Powder Extrusion (BPE) – Works like FDM printing but with metal-filled filaments.

Benefits of Metal 3D Printing

Why are metal 3D printers a game-changer?

✔ Stronger Parts – Create industrial-grade components for high-stress environments.

✔ Less Waste – Uses only the material needed, unlike subtractive manufacturing.

✔ Faster Prototyping – Speed up product development with on-demand production.

✔ Customization – Design complex geometries that traditional methods can’t achieve.

How to Choose the Right Metal 3D Printer

1. What’s Your Budget?

- Entry-level (under $100K) – Best for small businesses and research labs.

- Mid-range ($100K–$500K) – Ideal for industrial prototyping and small-scale production.

- High-end ($500K+) – Used by aerospace, medical, and automotive industries.

2. What Materials Do You Need?

Some printers specialize in stainless steel, aluminum, titanium, or copper, while others offer multi-material compatibility.

3. What’s Your Application?

- Aerospace & Automotive – Requires lightweight, high-strength metals like titanium.

- Medical & Dental – Needs biocompatible materials like cobalt chrome.

- Manufacturing – Prioritizes speed and scalability.

Top 10 Metal 3D Printers of 2024

1. Markforged Metal X

✅ Best for Small Businesses

Technology: Bound Powder Extrusion

Materials: Stainless Steel, Tool Steel, Copper

Price: ~$99,900

🔹 Why It Stands Out: Affordable, easy to use, and safe for office environments.

2. Desktop Metal Studio System 2

✅ Best for Rapid Prototyping

Technology: Bound Metal Deposition

Materials: Stainless Steel, Copper

Price: ~$110,000

🔹 Why It Stands Out: No hazardous metal powders, making it an office-friendly option.

3. SLM Solutions SLM 280

✅ Best for Industrial-Grade Printing

Technology: Selective Laser Melting (SLM)

Materials: Titanium, Aluminum, Stainless Steel

Price: ~$600,000

🔹 Why It Stands Out: High production speed with multi-laser capability.

4. EOS M 290

✅ Best for High Precision

Technology: Direct Metal Laser Sintering (DMLS)

Materials: Titanium, Aluminum, Nickel Alloys

Price: ~$700,000

🔹 Why It Stands Out: Industry benchmark for aerospace and medical applications.

5. 3D Systems DMP Flex 350

✅ Best for Medical and Aerospace

Technology: Direct Metal Printing (DMP)

Materials: Titanium, Stainless Steel, Cobalt Chrome

Price: ~$500,000

🔹 Why It Stands Out: High-resolution detail with low oxygen environment printing.

6. Velo3D Sapphire

✅ Best for Complex Geometries

Technology: Laser Powder Bed Fusion

Materials: Titanium, Inconel, Aluminum

Price: ~$700,000

🔹 Why It Stands Out: Support-free printing for intricate designs.

7. Renishaw RenAM 500Q

✅ Best for Speed

Technology: Laser Powder Bed Fusion

Materials: Titanium, Aluminum, Steel

Price: ~$650,000

🔹 Why It Stands Out: Quad-laser system for fast production.

8. Meltio M450

✅ Best for Hybrid Manufacturing

Technology: Directed Energy Deposition (DED)

Materials: Stainless Steel, Titanium, Nickel

Price: ~$100,000

🔹 Why It Stands Out: Works with CNC machines for hybrid manufacturing.

9. GE Additive Concept Laser M2

✅ Best for High-Volume Production

Technology: Laser Powder Bed Fusion

Materials: Titanium, Aluminum, Stainless Steel

Price: ~$800,000

🔹 Why It Stands Out: Trusted by aerospace and defense industries.

10. ExOne Innovent+

✅ Best Budget Option

Technology: Binder Jetting

Materials: Stainless Steel, Bronze, Copper

Price: ~$150,000

🔹 Why It Stands Out: Affordable and scalable metal printing.

Conclusion

Metal 3D printing is more accessible than ever. Whether you need an entry-level system or a high-performance industrial machine, there’s a perfect printer for your needs.

🚀 Which metal 3D printer interests you the most? Drop a comment below!

FAQs

1. What is the cheapest metal 3D printer?

📌 Markforged Metal X and ExOne Innovent+ are among the most affordable options.

2. Can metal 3D printers print aluminum?

📌 Yes! Many SLM and DMLS printers support aluminum.

3. Are metal 3D printed parts strong?

📌 Absolutely! They can match or even exceed the strength of traditionally manufactured parts.

4. How much does a metal 3D printer cost?

📌 Prices range from $100K to over $1M, depending on technology and features.

5. What industries use metal 3D printing?

📌 Aerospace, automotive, healthcare, and manufacturing lead the adoption of metal 3D printing. 🚀