How can I prevent filament degradation?

Preventing filament degradation is essential for ensuring that your 3D prints come out with high quality and performance. Filament degradation can happen due to various factors, such as exposure to moisture, heat, light, and air, which can affect the filament’s physical properties, making it more difficult to print with and resulting in poor print quality. Here are several ways to prevent filament degradation:

1. Store Filament Properly

- Why It Helps: Proper storage is key to preventing filament degradation, especially when it comes to moisture-sensitive filaments like Nylon, TPU, ABS, and PETG.

- How to Do It:

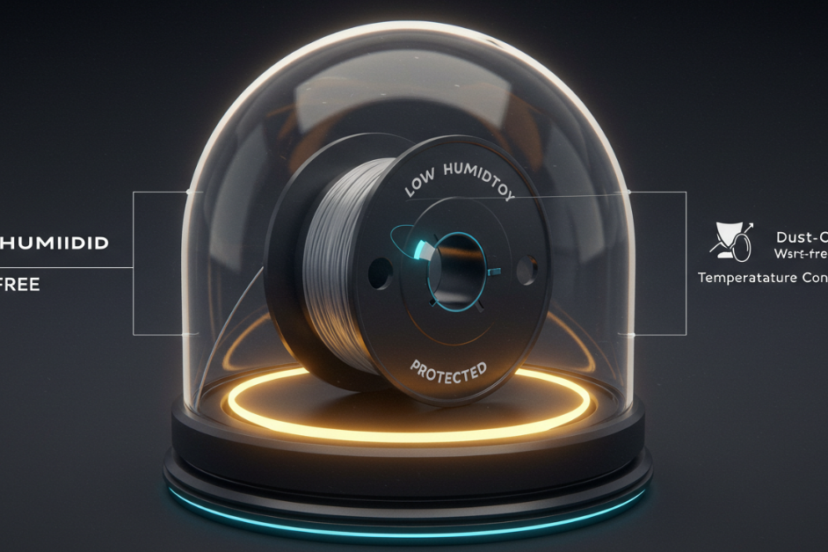

- Store filament in airtight containers or vacuum-sealed bags with desiccants (silica gel) to absorb moisture.

- Use a filament dry box or humidifier-controlled cabinet to maintain low humidity and prevent filament from absorbing moisture.

- Keep filament away from heat sources, direct sunlight, or high humidity areas like bathrooms or kitchens.

- Benefit: Reduces moisture exposure, which can cause issues like bubbling, stringing, or poor adhesion.

2. Keep Filament in a Cool, Dry Environment

- Why It Helps: Temperature fluctuations and high humidity can accelerate filament degradation by causing it to absorb moisture or break down faster.

- How to Do It:

- Store filament in a cool, dry place with a temperature range between 15°C and 25°C.

- Keep filament away from heat sources such as radiators, windows with direct sunlight, and near appliances that generate heat.

- Benefit: Maintaining stable, dry conditions helps keep the filament in its optimal state for printing.

3. Use Filament in a Timely Manner

- Why It Helps: Filament can degrade over time, even if it is stored properly, due to long exposure to environmental elements or improper storage.

- How to Do It:

- Try to use your filament within 6-12 months after purchase, depending on the type and storage conditions.

- If filament isn’t used in a while, make sure it is properly stored and checked for any signs of moisture or degradation before printing.

- Benefit: Prevents long-term degradation by using filament before it has the chance to absorb moisture or degrade physically.

4. Seal Filament After Opening

- Why It Helps: Once you open a spool of filament, it becomes exposed to air, which can lead to moisture absorption or contamination.

- How to Do It:

- Vacuum-seal filament after opening the packaging to keep it protected from environmental exposure.

- Use airtight resealable bags to store filament after opening if vacuum-sealing is not an option.

- Add desiccant packs inside the storage container to absorb any moisture.

- Benefit: Sealing the filament after opening reduces its exposure to moisture, dust, and air, helping to prevent degradation.

5. Use a Filament Dryer

- Why It Helps: Moisture is one of the primary causes of filament degradation. Filament dryers remove moisture from filament before use, ensuring it prints well.

- How to Do It:

- Use a filament dryer or oven (at a low temperature, around 40°C-50°C) to dry filament before printing, especially if it’s been stored for a while or in a humid environment.

- Benefit: Drying filament before use eliminates moisture that could cause print issues like bubbles, poor layer bonding, or brittleness.

6. Limit Exposure to UV Light

- Why It Helps: UV light can degrade filament, particularly PLA, causing it to become brittle, lose color, or degrade its mechanical properties.

- How to Do It:

- Store filament in opaque containers or sealed bags that block UV rays.

- Keep filament away from direct sunlight and any UV light sources.

- Benefit: Protects filament from UV degradation, ensuring it retains its color and mechanical properties.

7. Monitor Storage for Signs of Degradation

- Why It Helps: Even with the best storage practices, it’s important to periodically check filament for signs of moisture or degradation.

- How to Do It:

- Inspect filament regularly for any visible signs of moisture absorption, such as clumping, brittleness, or surface changes.

- Check for discoloration or fragility in the filament. These are signs it may have been exposed to moisture or UV light.

- Benefit: Detecting early signs of degradation allows you to address any issues before they affect your prints.

8. Use High-Quality Filament

- Why It Helps: Higher-quality filament is more resistant to degradation due to better manufacturing processes and more stable material properties.

- How to Do It:

- Choose filament from reputable brands with good reviews and manufacturing standards.

- Check the filament certifications for quality and moisture resistance.

- Benefit: High-quality filament will degrade slower, print more reliably, and yield higher-quality results.

9. Store Filament Spools on Racks or Hangers

- Why It Helps: Storing filament improperly (such as on the floor or in a disorganized pile) can cause physical damage, tangling, or bending of the filament, which can affect its performance.

- How to Do It:

- Store filament spools on spool racks, wall-mounted holders, or storage bins designed for easy access and organization.

- Keep spools off the floor to prevent them from being exposed to dust or physical damage.

- Benefit: Organized storage helps prevent tangling, bending, or physical damage to the filament, ensuring it’s ready for smooth printing.

Summary of How to Prevent Filament Degradation:

- Store in Airtight Containers or vacuum-sealed bags with desiccants.

- Keep Filament in a Cool, Dry Environment at stable temperatures (15°C to 25°C).

- Use Filament in a Timely Manner, ideally within 6-12 months of purchase.

- Seal Filament After Opening using airtight resealable bags or vacuum-sealing.

- Use a Filament Dryer to remove moisture before printing.

- Limit Exposure to UV Light by storing filament in opaque containers.

- Monitor Storage for Signs of Degradation, such as moisture, brittleness, or discoloration.

- Choose High-Quality Filament from trusted brands to prevent early degradation.

- Store Spools on Racks or Hangers to avoid tangling or physical damage.

By following these steps, you can significantly reduce filament degradation, preserve its quality, and ensure that you’re getting the best possible performance from your 3D printing materials.