How do I dry TPU filament?

Drying TPU (Thermoplastic Polyurethane) filament is essential to prevent moisture-related printing issues such as bubbling, poor layer adhesion, and inconsistent extrusion. While TPU is less hygroscopic compared to materials like Nylon, it can still absorb moisture over time. Here’s how you can dry TPU filament effectively:

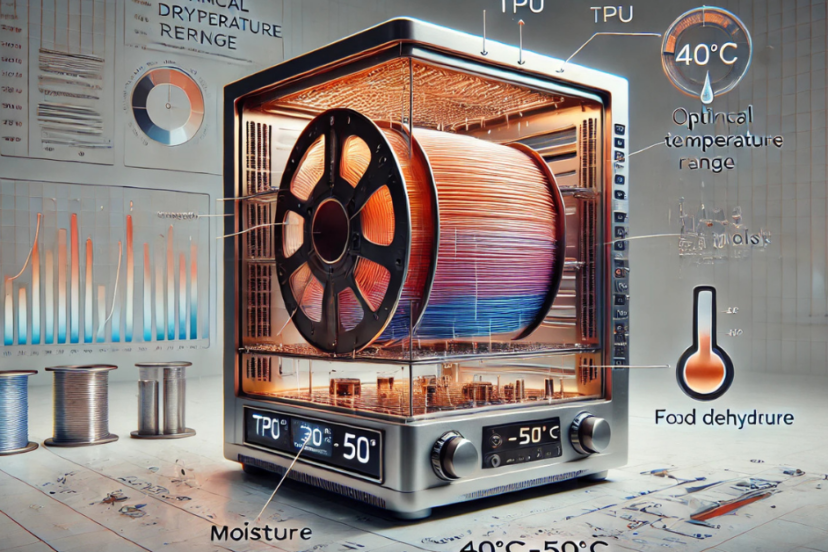

1. Use a Filament Dryer

- Why It Works: Filament dryers are designed specifically for removing moisture from filament. They provide a controlled, low-temperature environment that ensures your TPU filament dries without overheating or degrading.

- How to Do It:

- Place the TPU filament spool inside the filament dryer.

- Set the dryer to a temperature of around 40°C to 50°C (104°F to 122°F).

- Let the filament dry for 4 to 6 hours, depending on the moisture content.

- Benefit: Filament dryers are easy to use and ensure consistent drying without the risk of damaging the filament.

2. Use an Oven

- Why It Works: An oven can be used as a DIY solution for drying TPU filament. However, you need to be cautious with the temperature to avoid overheating the material.

- How to Do It:

- Preheat the oven to 40°C to 50°C (104°F to 122°F). Make sure the temperature doesn’t exceed 60°C, as TPU can start to soften at higher temperatures.

- Place the filament spool on a baking tray or in an oven-safe container.

- Dry the filament for 4 to 6 hours.

- Tip: Keep the oven door slightly ajar to allow moisture to escape.

- Benefit: The oven provides an affordable option for drying filament, but it requires careful temperature monitoring.

3. Use a Food Dehydrator

- Why It Works: A food dehydrator is another reliable and efficient method to dry TPU filament. It provides consistent airflow and low heat to remove moisture without causing damage to the filament.

- How to Do It:

- Set the dehydrator to a temperature of 40°C to 50°C (104°F to 122°F).

- Place the TPU spool inside the dehydrator and let it dry for 4 to 6 hours.

- Benefit: A food dehydrator is a dedicated drying tool that ensures even moisture removal and is ideal for drying multiple filaments at once.

4. Use a Desiccant Dry Box

- Why It Works: A desiccant dry box is a storage solution that uses moisture-absorbing desiccants (like silica gel) to keep the filament dry. While not an active drying method, it can be used to prevent moisture from affecting TPU filament during storage.

- How to Do It:

- Place the TPU filament spool in a desiccant dry box with desiccant packets.

- Ensure the box is airtight to maintain a dry environment.

- For initial drying, leave the filament in the box with desiccants for 24-48 hours.

- Benefit: A desiccant dry box is an excellent way to prevent moisture absorption during storage and can be used for maintaining dry filament over time.

5. Drying with a Vacuum Sealer

- Why It Works: If you have a vacuum sealer, it can be used to seal TPU filament in a moisture-proof bag along with desiccant packets.

- How to Do It:

- Place the filament spool in a vacuum-sealed bag with silica gel desiccants.

- Use the vacuum sealer to remove air from the bag, creating a sealed, moisture-proof environment.

- Store the sealed bag in a dry place or leave it for a couple of days to allow the desiccants to absorb moisture.

- Benefit: This method helps keep the filament dry over extended periods and prevents it from absorbing moisture in the future.

Important Tips for Drying TPU:

- Temperature Control: TPU is a flexible material, and overheating it can lead to deformation. Always dry it at a low temperature, ideally between 40°C and 50°C, to avoid damaging the filament.

- Storage: After drying TPU, store it in an airtight container or vacuum-sealed bag with desiccants to prevent moisture absorption.

- Monitor Filament Regularly: Even if TPU filament appears dry, it may still absorb moisture during storage. Dry it periodically if you notice any printing issues such as bubbling or poor adhesion.

By following these drying methods, you can ensure that your TPU filament stays in optimal condition, preventing moisture-related issues and achieving better print quality.