How Does Vacuum-Sealing Compare to Other Filament Storage Methods in Terms of Cost and Effectiveness?

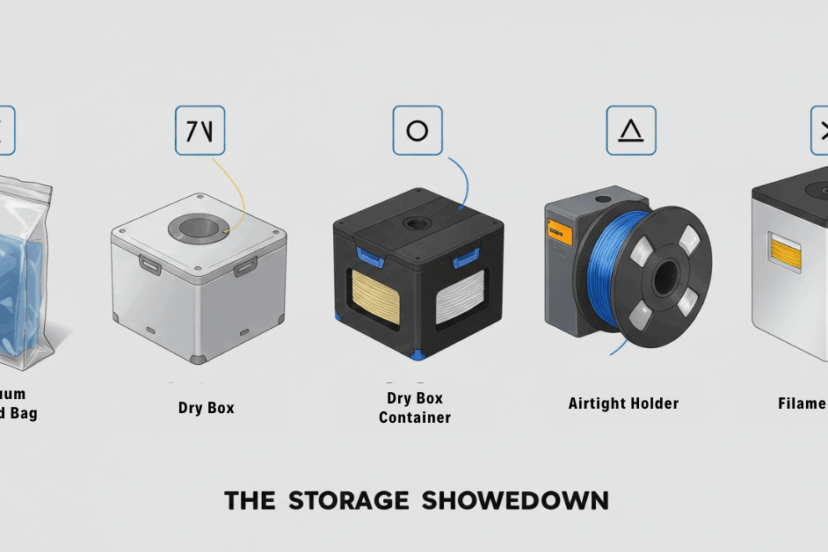

When it comes to storing 3D filament, there are various methods available, each with its pros and cons. Vacuum-sealing is one of the most effective options for keeping filament dry and free from moisture, but how does it compare to other filament storage methods in terms of cost and effectiveness? Let’s break down how vacuum-sealing stacks up against other popular storage solutions like dry boxes, airtight containers, and spool holders.

1. Vacuum-Sealing vs. Dry Boxes

Cost Comparison:

- Vacuum-Sealing: The initial cost of a vacuum sealer and vacuum-sealing bags can range from $30 to $200, depending on the quality of the vacuum sealer. However, once you have the equipment, you can use it for an extended period with minimal additional costs (mainly replacement bags and desiccants).

- Dry Boxes: A good filament dry box can cost anywhere from $30 to $150, with higher-end models equipped with features like humidity control, heating elements, and automatic filament feeding. Some high-quality dry boxes designed for moisture-sensitive filaments can be more expensive.

Effectiveness:

- Vacuum-Sealing: Vacuum-sealing is extremely effective for long-term filament storage, especially for moisture-sensitive materials like Nylon and TPU. It removes air from the bag, reducing the risk of moisture absorption and protecting the filament from environmental contaminants. However, it requires manual resealing after each use, which can be inconvenient for active printing.

- Dry Boxes: Dry boxes are excellent for active use, as they allow you to keep filament in a moisture-controlled environment while you print. They can maintain low humidity levels (often between 20% and 40% RH) and prevent moisture absorption during printing sessions. However, dry boxes are less effective for long-term storage unless they feature a desiccant system or temperature control.

Conclusion:

- Vacuum-Sealing is generally more cost-effective for long-term storage but can be inconvenient if you need easy access to filament for active printing.

- Dry Boxes are better suited for active printing, and although they may come with a higher price tag, they provide continuous humidity control and allow for easy access to filament.

2. Vacuum-Sealing vs. Airtight Containers

Cost Comparison:

- Vacuum-Sealing: As mentioned earlier, the cost of a vacuum sealer is typically between $30 to $200, with additional costs for bags and desiccants. Vacuum-sealing bags are a consumable item, so you’ll need to replace them over time.

- Airtight Containers: Airtight containers can range from $10 to $50 for a basic container. High-quality, large airtight containers may cost more, but these are generally a one-time purchase with no ongoing costs other than desiccants (if used).

Effectiveness:

- Vacuum-Sealing: Vacuum-sealing provides a stronger seal and better moisture protection compared to airtight containers, especially because it removes air from the bag entirely. The vacuum-sealed environment is ideal for long-term storage and protects filament from humidity and contaminants.

- Airtight Containers: Airtight containers provide basic moisture protection, but they may not remove all the air from the container, meaning some moisture can still be present. They are less effective than vacuum-sealing in terms of maintaining a completely dry environment. However, they are more convenient for quick access to filament, as you don’t need to reseal them every time you open them. Conclusion:

- Vacuum-Sealing is more effective for long-term storage and moisture-sensitive filaments, but airtight containers offer easier access and are cheaper, making them a great option for short-term or regular filament use. If you’re looking for maximum protection over extended periods, vacuum-sealing is the better choice.

3. Vacuum-Sealing vs. Spool Holders

Cost Comparison:

- Vacuum-Sealing: As previously discussed, vacuum-sealing requires a vacuum sealer and vacuum bags, which come with a higher initial cost. For storing multiple spools, you’ll need extra bags, which can add up over time.

- Spool Holders: Spool holders, which are designed to keep your filament organized and accessible, are much cheaper—usually ranging from $10 to $30 for basic models. Higher-end models with features like filament guides or humidity controls can cost more.

Effectiveness:

- Vacuum-Sealing: Provides the most effective long-term storage solution for filament, particularly for moisture-sensitive materials. It ensures that filament is stored in an airtight, moisture-free environment, extending the filament’s shelf life.

- Spool Holders: Spool holders are not meant for long-term storage and do not provide moisture protection. They are best suited for keeping filament organized and accessible during active printing. While they may have a small desiccant compartment, they don’t offer the same level of moisture protection as vacuum-sealing.

Conclusion:

- Vacuum-Sealing is the superior option for moisture protection and long-term filament storage. On the other hand, spool holders are excellent for short-term access and organization but provide no protection against moisture or contaminants.

4. Vacuum-Sealing vs. Filament Dryers

Cost Comparison:

- Vacuum-Sealing: The initial cost of a vacuum sealer ranges from $30 to $200, with minimal ongoing costs other than replacement bags.

- Filament Dryers: Filament dryers can be quite expensive, typically costing between $50 to $200 for a quality model. Some high-end filament dryers may even include heating elements and humidity sensors, which add to the price.

Effectiveness:

- Vacuum-Sealing: Vacuum-sealing provides long-term storage protection, especially for preventing moisture absorption. However, it is not designed to actively dry filament before or during printing. If your filament is already wet, you’ll need to use a filament dryer before printing.

- Filament Dryers: Filament dryers are specifically designed to remove moisture from filament. They are highly effective at drying filament before printing, ensuring high-quality prints. However, they do not provide long-term storage like vacuum-sealing or dry boxes. Once filament is dry, it should be stored in an airtight container or vacuum-sealed bag to keep it dry.

Conclusion:

- Vacuum-Sealing is more cost-effective for long-term storage, but filament dryers are essential for drying wet filament before printing. If moisture is a concern, it’s best to use both: a filament dryer to remove moisture and a vacuum-sealed bag for long-term storage.

Summary: Vacuum-Sealing vs. Other Storage Methods

| Method | Cost | Effectiveness | Best For |

|---|---|---|---|

| Vacuum-Sealing | Medium to High | Best for long-term storage, especially for moisture-sensitive filaments. Requires resealing after each use. | Long-term storage of sensitive filaments |

| Dry Boxes | Medium to High | Excellent for active use with continuous moisture control. | Active printing with easy access |

| Airtight Containers | Low to Medium | Good for short-term storage, but not as moisture-proof as vacuum-sealing. | Short-term storage and easy access |

| Spool Holders | Low | Best for organization; offers no moisture protection. | Organization and active use |

| Filament Dryers | Medium to High | Best for drying wet filament; not intended for long-term storage. | Drying filament before printing |

Conclusion:

- Vacuum-Sealing is the most effective method for long-term filament storage, particularly for moisture-sensitive filaments. It provides excellent moisture protection, but requires resealing after each use.

- Dry boxes are better for active printing because they allow easy access to filament while maintaining humidity control, but they can be more expensive.

- Airtight containers and spool holders are more affordable and offer basic moisture protection but are less effective than vacuum-sealing for long-term storage.

- Filament dryers are crucial if you need to dry filament before printing but don’t offer storage solutions.

Choosing the right storage method depends on your storage needs, budget, and how often you access your filament. If you need a cost-effective solution for long-term storage, vacuum-sealing is an excellent choice, while dry boxes are better for those needing constant access to filament for active printing.