How can I improve filament storage?

Improving filament storage is crucial for maintaining filament quality and ensuring consistent, high-quality 3D prints. Proper storage helps prevent moisture absorption, contamination, and degradation, all of which can negatively affect your prints. Here are several ways to improve your filament storage:

1. Store Filament in Airtight Containers

- Why It Helps: Filament is highly susceptible to moisture absorption, especially materials like Nylon, TPU, ABS, and PETG. Moisture can cause issues like stringing, popping, and weak prints.

- How to Do It: Use airtight containers, plastic bins, or vacuum-sealed bags to keep filament in a sealed environment. Adding desiccant packs (silica gel) inside these containers will help absorb any moisture.

- Benefit: Airtight storage keeps moisture away and prevents filament from degrading over time.

2. Use a Filament Dry Box

- Why It Helps: A filament dry box is designed to maintain an ideal low-humidity environment for your filament. Some models also feature heating elements to dry filament as it feeds into the printer.

- How to Do It: Store your filament rolls in a dry box, and if your box has a humidity control feature, set it to the recommended level (usually between 20% and 40% RH).

- Benefit: Filament dry boxes actively maintain moisture control and prevent filament from absorbing water, ensuring high-quality prints every time.

3. Vacuum Seal Filament Rolls

- Why It Helps: Vacuum sealing removes air from the storage bag, preventing filament from coming into contact with moisture, dust, or contaminants. It also compresses the filament, reducing the space required for storage.

- How to Do It: Use a vacuum sealer to seal the filament spool in a vacuum bag. You can also add desiccant packets inside the bag to absorb moisture.

- Benefit: Vacuum sealing ensures moisture protection and space efficiency, making it an ideal storage method for long-term storage, especially for moisture-sensitive filaments like Nylon.

4. Keep Filament in a Cool, Dry Place

- Why It Helps: Temperature and humidity fluctuations can degrade filament quality over time, especially for materials like Nylon, which is highly sensitive to both moisture and temperature.

- How to Do It: Store filament in a climate-controlled environment that is cool (ideally between 15°C and 25°C) and dry (around 40-60% relative humidity). Avoid storing filament near windows, heat sources, or humid areas like bathrooms and kitchens.

- Benefit: A stable, cool, dry environment prevents filament from becoming brittle, warped, or damaged.

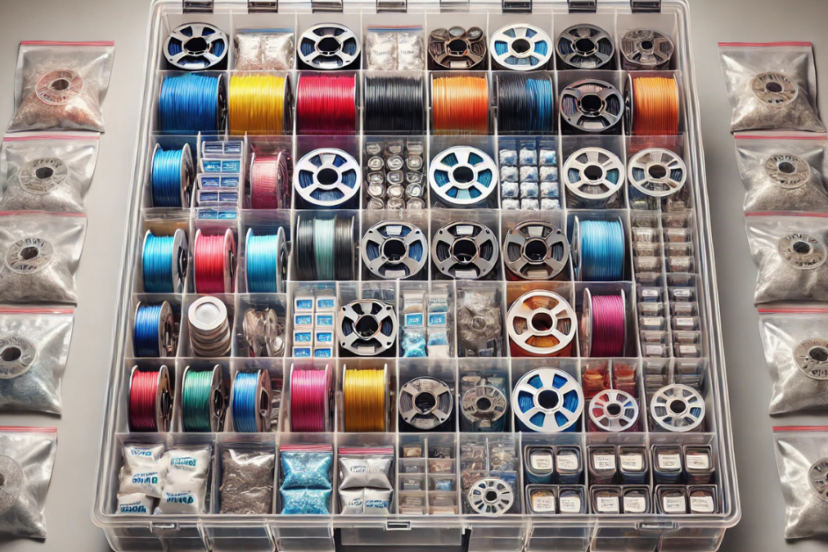

5. Organize Filament by Type and Usage

- Why It Helps: Keeping filament organized helps you quickly access the right material when you need it and prevents spools from getting tangled or damaged.

- How to Do It: Store filaments in separate containers or storage racks based on type (e.g., PLA, ABS, PETG, Nylon). Label containers with the filament type, color, and any other relevant information.

- Benefit: Organized filament storage saves time and helps prevent errors, such as using the wrong filament type for your print.

6. Use Filament Spool Hangers

- Why It Helps: Filament spools can become tangled or damaged if left in piles or improperly stored. Spool hangers help to keep filament organized and prevent it from getting twisted or kinked.

- How to Do It: Use a filament spool rack or wall-mounted hangers to store filament spools. You can also use filament spools with built-in storage compartments for easy access.

- Benefit: Keeping filament spools neatly stored on hangers or racks prevents tangling, allowing for smoother printing and easier access.

7. Control Exposure to UV Light

- Why It Helps: UV light can degrade certain filaments, especially PLA, which can become brittle or lose its color after prolonged exposure to sunlight.

- How to Do It: Store filament in opaque containers or boxes that block UV light, or store them in a dark drawer or closet. If using clear storage, consider UV-resistant bags.

- Benefit: Protecting filament from UV light helps preserve its mechanical properties and color over time.

8. Avoid Storing Filament on the Floor

- Why It Helps: Storing filament on the floor exposes it to temperature fluctuations, dust, and potential physical damage.

- How to Do It: Keep filament on shelves, racks, or storage cabinets to protect it from dirt, moisture, and impact. Elevated storage keeps filament safe and organized.

- Benefit: Keeping filament off the floor ensures it’s stored in a cleaner, more stable environment, helping it maintain quality.

9. Regularly Check for Moisture or Damage

- Why It Helps: Even with the best storage methods, it’s a good idea to periodically check filament for signs of moisture or damage, especially if it’s been stored for a while.

- How to Do It: Inspect filament spools for any visible signs of moisture absorption (such as bubbling or clumping) or physical damage (like cracks or dents).

- Benefit: Regular checks help you identify any issues early on, allowing you to address moisture problems by drying the filament or replacing damaged spools before using them in your printer.

10. Use Silica Gel or Moisture Absorbers

- Why It Helps: Silica gel and other moisture-absorbing materials help prevent moisture from accumulating inside storage containers, especially in areas with high humidity.

- How to Do It: Place silica gel packets or moisture-absorbing materials in storage containers, vacuum-sealed bags, or dry boxes to keep filament dry.

- Benefit: Silica gel ensures that moisture levels remain low, even if there is some ambient humidity in the storage area.

Summary of Tips to Improve Filament Storage:

- Use Airtight Containers or vacuum-sealed bags with desiccants to protect filament from moisture.

- Store in a Cool, Dry Place to prevent environmental damage and preserve filament quality.

- Use Filament Dry Boxes to actively control humidity and prevent moisture absorption.

- Organize Filament by type and usage to keep things tidy and easy to find.

- Store Filament on Spool Hangers to prevent tangling and physical damage.

- Protect from UV Light by using opaque containers or dark storage spaces.

- Avoid Storing on the Floor to prevent exposure to dust, dirt, and temperature fluctuations.

- Check Filament Regularly for signs of moisture or damage, especially if stored for a long period.

- Use Silica Gel or Moisture Absorbers to ensure humidity levels stay low.

By following these filament storage practices, you can maintain the quality and usability of your filament, reduce the risk of print failures, and extend the lifespan of your 3D printing materials.