What are alternatives to Nylon filament?

If you’re looking for alternatives to Nylon filament for 3D printing, there are several options that offer similar benefits in terms of strength, flexibility, and durability. These alternatives may have different characteristics suited to specific needs and applications. Here are some of the best alternatives to Nylon filament:

1. Polycarbonate (PC)

- Properties: Polycarbonate is a strong, durable, and impact-resistant material, similar to Nylon. It has excellent heat resistance, high tensile strength, and good optical clarity.

- Advantages:

- Very strong and tough, making it suitable for functional parts and prototypes.

- High heat resistance (up to 115°C or 239°F), making it ideal for high-temperature applications.

- Applications: Automotive parts, electrical housings, functional prototypes, and mechanical components.

- Challenges: Polycarbonate requires high printing temperatures (about 270°C) and a heated bed to prevent warping.

2. PETG (Polyethylene Terephthalate Glycol)

- Properties: PETG is a strong and flexible filament that combines the best features of PLA and ABS. It is easier to print than Nylon, with less tendency to absorb moisture.

- Advantages:

- Strong and durable, offering good impact resistance and flexibility.

- Resistant to chemicals, moisture, and UV light.

- Low warping, which makes it easier to print.

- Applications: Household items, bottles, containers, and functional parts.

- Challenges: PETG has a lower heat resistance compared to Nylon or Polycarbonate, but it’s still suitable for many practical applications.

3. ABS (Acrylonitrile Butadiene Styrene)

- Properties: ABS is one of the most popular 3D printing materials due to its strength, durability, and resistance to high temperatures.

- Advantages:

- High impact resistance and toughness, similar to Nylon.

- Good for functional parts that will undergo stress and wear.

- Can be easily post-processed (e.g., smoothed with acetone).

- Applications: Automotive parts, toys, tools, and household objects.

- Challenges: ABS can be difficult to print with due to its tendency to warp. It requires a heated bed and good ventilation due to the fumes it produces while printing.

4. ASA (Acrylonitrile Styrene Acrylate)

- Properties: ASA is similar to ABS but with improved UV resistance and weatherability. It is more suitable for outdoor applications than Nylon, with excellent strength and toughness.

- Advantages:

- UV-resistant and weatherproof, making it ideal for outdoor use.

- Strong and durable, with excellent chemical resistance.

- Easier to print than ABS, with less warping.

- Applications: Automotive parts, outdoor equipment, and functional prototypes exposed to sunlight.

- Challenges: Requires a heated bed and enclosure for optimal printing conditions.

5. Polypropylene (PP)

- Properties: Polypropylene is a lightweight and flexible filament that is chemically resistant and durable. It is commonly used in manufacturing and industrial applications.

- Advantages:

- Excellent chemical resistance, especially to acids, bases, and solvents.

- Good fatigue resistance and flexibility.

- Lightweight and easy to print, with low warping.

- Applications: Storage containers, functional prototypes, and automotive parts.

- Challenges: Printing with Polypropylene can be challenging due to its poor bed adhesion, but using a heated bed and specific adhesives can help.

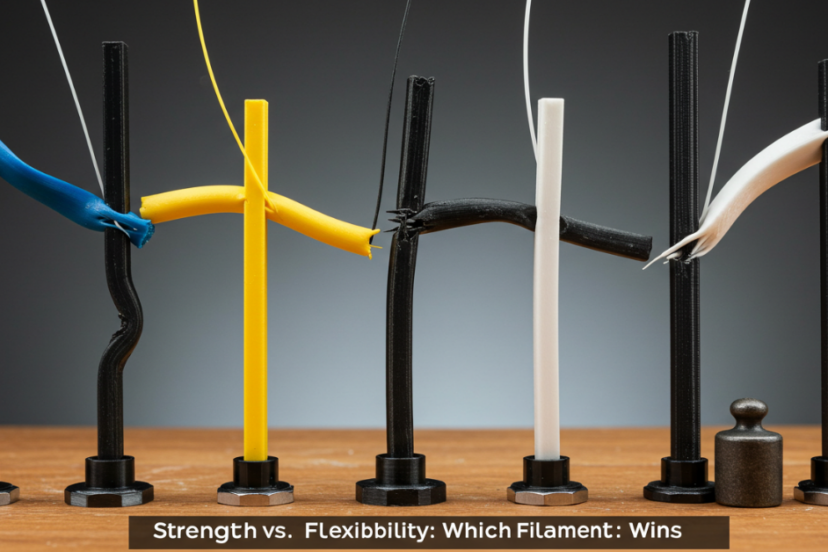

6. TPU (Thermoplastic Polyurethane)

- Properties: TPU is a flexible, rubber-like filament that offers excellent impact resistance and elasticity, making it a good alternative to Nylon when flexibility is needed.

- Advantages:

- Highly flexible and elastic, ideal for parts that need to bend or stretch (e.g., phone cases, gaskets, and wearables).

- Good abrasion resistance and shock absorption properties.

- Applications: Phone cases, flexible hinges, seals, and rubber-like parts.

- Challenges: TPU can be more challenging to print due to its flexibility, requiring slower print speeds and precise extrusion control.

7. PVA (Polyvinyl Alcohol)

- Properties: PVA is a water-soluble filament often used as a support material in dual-extrusion 3D printing. It is not as strong as Nylon but is useful for complex prints that require dissolvable support structures.

- Advantages:

- Soluble in water, making it ideal for printing intricate parts with complex geometries that require support material.

- Works well for models with overhangs and internal features that are hard to support with traditional materials.

- Applications: Support material for complex prints, mold making, and detailed prototypes.

- Challenges: PVA has limited strength and durability, so it’s best used in combination with other filaments like PLA or ABS for structural parts.

8. High-Temperature PLA (HTPLA)

- Properties: High-temperature PLA is an enhanced version of traditional PLA, offering better heat resistance and mechanical properties.

- Advantages:

- Easier to print than other high-performance filaments, such as Nylon.

- Has a higher heat resistance (up to 120°C) than standard PLA, making it a good alternative for parts that may be exposed to higher temperatures.

- Applications: Functional prototypes, decorative items, and parts that need some heat resistance.

- Challenges: Not as strong as Nylon, but a great option for lower-temperature applications.

Conclusion:

When choosing an alternative to Nylon, the best option depends on the specific requirements of your print, such as strength, flexibility, heat resistance, and ease of printing. Polycarbonate, PETG, and ABS are all great alternatives when strength and durability are needed, while TPU is a good choice if flexibility is a priority. For outdoor or weather-resistant applications, ASA and Polypropylene are strong contenders. Each filament has its pros and cons, so it’s important to choose the right material based on the demands of your project.