How should I label and track my filament in storage containers?

1. Introduction: Don’t Lose Track of Your Filament

Ever found a spool in your bin and thought:

“Wait… when did I dry this?”

“Is this PLA or PETG?”

“Was this used for something important?”

That’s why labeling and tracking your filament containers is key to a smooth 3D printing workflow.

2. Why Labeling and Tracking Matter

Without proper labels, you risk:

❌ Reprinting with brittle or moist filament

❌ Mixing up filament types

❌ Over-drying or forgetting to dry altogether

❌ Re-buying materials you already have

Good labeling = less waste, more efficiency.

3. Key Info You Should Always Label

For each container or spool, include:

- 🎯 Filament type (PLA, PETG, etc.)

- 🌈 Color name or code

- 🏷️ Brand + material line (e.g., eSUN PLA+, Hatchbox PETG)

- 🔄 Dry date (last dried or received)

- 💧 Humidity check date

- 💊 Desiccant recharge date

- ✍️ Notes (used for prototype, scrap-only, etc.)

Simple labels = smarter decisions.

4. Best Places to Attach Labels

| Location | Pros | Notes |

|---|---|---|

| Container lid | Easy to see from top | Great for bins |

| Front side | Visible when stacked | Works best for clear boxes |

| Inside lid | Hidden but safe | Add dry/due dates |

| On spool | Personalizes each reel | Use masking tape or print stickers |

Use permanent marker or write-on labels that won’t smudge.

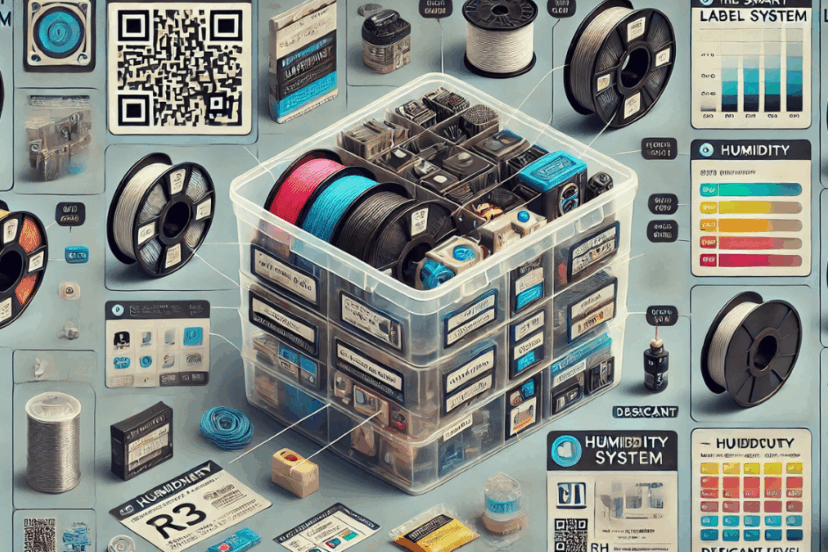

5. Labeling Options: Stickers, Tape, or Digital?

| Method | Pros | Best For |

|---|---|---|

| Masking tape | Cheap, flexible | Spools + bins |

| Chalkboard labels | Reusable | Clear bins |

| Label maker | Clean + uniform | Permanent setups |

| QR codes | Digital access to logs | Shared workspaces |

| Dry erase tags | Rewritable | Quick swaps |

You don’t need fancy tools—just something clear and consistent.

6. Color Coding for Quick Identification

Use colored tape or labels to represent:

- 🔴 PLA

- 🟢 PETG

- 🔵 ABS

- 🟡 Nylon

- 🟣 TPU

Or color-code by dry status:

- 🟢 Green = ready to print

- 🟡 Yellow = dry soon

- 🔴 Red = needs drying

This helps when scanning through multiple bins or spools.

7. Tracking Dry Dates and Reuse Cycles

💡 Add a “Dried On” and “Next Check” section on each label.

Rotate your filament based on:

- Last dried date

- Humidity card status

- Desiccant status

- Whether it’s opened or vacuum-sealed

Tip: Keep reusable spools in a “print first” section to reduce waste.

8. Should You Track Storage Temperature and RH?

Optional but helpful:

- Use a mini RH log for each bin

- Record average RH over time

- Add notes on temp swings if stored in garage/basement

This helps diagnose failed prints caused by storage—not slicer settings.

9. How to Track Desiccant Replacement

Label each container or card with:

- ✅ “Desiccant Added: [date]”

- 🔁 “Recharge Due: [2–4 weeks later]”

- 💬 Add indicator color (e.g. “Pink = recharge soon”)

This way, you won’t be guessing when the silica gel last got a spa day.

10. Tips for Labeling Vacuum-Sealed Filament

For vac-sealed bags:

- Write info on masking tape on the outside

- Add humidity card and a color-changing silica pack inside

- Optionally place a mini label inside the bag for backup

Label before sealing. Nothing’s worse than opening 5 bags just to find one spool.

11. Best Tools for Easy Filament Labeling

🛠️ Recommended gear:

- Permanent marker (fine tip)

- Masking tape or painter’s tape

- Label maker (Brother P-Touch or Dymo LetraTag)

- Reusable tags with binder clips

- Printable filament ID cards (customizable for brands/colors)

Bonus: Print your own tags using a 3D printer and blank inserts.

12. Using Apps or Spreadsheets for Inventory

Track filament like a pro:

- 📊 Use Google Sheets or Airtable to log spools

- 📱 Try Filamentory or 3DPrinterOS for inventory

- 🔄 Log use by weight or color

- ⏳ Track lifespan of opened spools

You can even add QR codes to labels that link to your digital log!

13. How to Create a Simple Labeling System

Keep it easy:

- Line 1: Material + Brand (e.g., PLA+, Overture)

- Line 2: Color + Spool weight

- Line 3: Date dried / opened

- Line 4: Status (Ready to use / Dry soon)

Print these labels or fill them in with a marker.

Simple, neat, effective.

14. Labeling Ideas for Shared or Multi-Printer Workspaces

In team environments:

✅ Use color-coded tags for assigned printers or users

✅ Add initials to each spool label

✅ Track usage history (project/date/weight used)

✅ Have a “label-before-store” policy so no one leaves things untagged

It reduces filament mix-ups and printing delays.

15. Final Thoughts: A Little Labeling Goes a Long Way

If you’ve invested in good storage…

You owe it to yourself to keep it organized and traceable.

✅ Label every bin and spool

✅ Track drying and RH status

✅ Use simple tools that you’ll actually stick with

✅ Don’t let “mystery filament” ruin a good print

Clear labels = clean prints. Every time.

❓FAQs

- What kind of tape is best for labeling filament spools?

Masking or painter’s tape is easy to write on and remove. Label maker tape is great for longer-term use. - How often should I update my labels?

Any time the filament is dried, moved, or used. Also, after desiccant swaps or RH changes. - Do I need to label every individual spool?

Yes—especially if you have multiple brands or materials in a single bin. - What’s the easiest way to keep track of when filament was dried?

Write the “Dried On” date directly on the label or use a mini calendar log taped to the bin. - Can I use QR codes or apps to track filament storage?

Absolutely! Many makers link QR labels to spreadsheets or inventory apps for easy scanning.