3D Printing: Revolutionizing Manufacturing, One Layer at a Time

3D Printing and Its Impact on Manufacturing

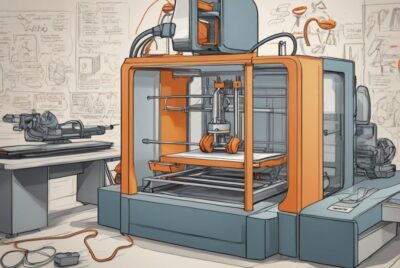

The world of manufacturing has experienced a paradigm shift with the introduction of 3D printing technology. As an avid enthusiast and advisor, I am truly fascinated by the endless possibilities this innovative technology brings to the table. In this article, I will provide you with a comprehensive understanding of 3D printing, its working principles, various types of printers, applications in different industries, and future trends. So, let’s dive right into the revolutionizing power of 3D printing in manufacturing!

How 3D Printing Works: Layer-by-Layer Additive Process

At its core, 3D printing is an additive manufacturing process that involves creating three-dimensional objects layer by layer. Unlike traditional subtractive manufacturing methods that involve cutting or drilling material to create a shape, 3D printing builds objects from the ground up. This revolutionary approach enables greater design flexibility and complexity. The process begins with creating a digital 3D model of the desired object using computer-aided design (CAD) software.

Once the 3D model is ready, it is sliced into thin cross-sectional layers. These slices serve as a blueprint for the 3D printer to follow. The printer then deposits or solidifies material, layer by layer, based on the instructions provided by the sliced model. The materials used in 3D printing can vary widely, ranging from plastics and metals to ceramics and even organic compounds. This versatility allows for the production of a vast array of objects with different properties and characteristics.

Different Types of 3D Printers and Their Applications

3D printers come in various types, each catering to specific applications and requirements. Let’s explore some of the most common types and their respective applications:

FDM (Fused Deposition Modeling) Printers: Enabling Innovation and Efficiency

FDM printers are the most widely used and affordable type of 3D printers. They work by melting thermoplastic filaments and depositing them layer by layer to build the object. FDM printers are versatile and find applications in rapid prototyping, educational settings, and small-scale manufacturing.

SLA (Stereolithography) Printers: Precision and Elegance Unleashed

SLA printers utilize a process called photopolymerization, where liquid resin is cured by a UV laser to create solid layers. These printers excel in producing highly detailed and intricate objects with smooth surface finishes. SLA printers are commonly used in the jewelry, dental, and artistic industries.

SLS (Selective Laser Sintering) Printers: Redefining Complex Manufacturing

SLS printers employ a laser to selectively fuse powdered materials, such as plastics or metals, to form the desired object. The powdered material serves as both the build material and the support structure, making SLS ideal for creating complex geometries. Industries like aerospace and automotive often leverage SLS printers for rapid prototyping and low-volume production.

Pros and Cons of 3D Printing Technology: Unlocking New Possibilities

As with any technology, 3D printing has its own set of advantages and limitations. Let’s take a closer look at both:

Advantages of 3D Printing

Design Freedom: 3D printing allows for intricate designs and complex geometries that would be challenging or impossible with traditional manufacturing methods.

Rapid Prototyping: The ability to quickly iterate and produce prototypes significantly speeds up the product development process.

Customization: 3D printing enables on-demand manufacturing, making it possible to create personalized products tailored to individual needs.

Reduced Material Waste: Additive manufacturing is inherently more sustainable than subtractive methods, as it only uses the necessary amount of material for production.

Limitations and Challenges of 3D Printing

Limited Material Choices: While the range of materials used in 3D printing is expanding, it still lags behind the vast selection available in traditional manufacturing.

Post-Processing Requirements: Depending on the printing technology and material used, post-processing steps like sanding, polishing, or curing may be necessary to achieve the desired finish.

Production Speed: 3D printing is generally slower compared to traditional manufacturing processes, which can hinder mass production.

Cost: While the cost of 3D printers has significantly decreased over the years, the materials and maintenance costs can still be relatively high.

Examples of 3D Printing in Various Industries

The impact of 3D printing can be witnessed across diverse industries. Here are some notable examples:

Automotive Industry

Automakers utilize 3D printing for rapid prototyping of car parts, reducing lead times and costs associated with traditional manufacturing methods. Additionally, customized interior components and lightweight, optimized designs are made possible through additive manufacturing.

Healthcare Industry

In the medical field, 3D printing has revolutionized patient-specific treatment. Surgeons can now create accurate anatomical models to plan complex surgeries or produce tailor-made implants and prosthetics. Bioprinting, a promising field within healthcare, aims to create functional human tissues and organs using 3D printing techniques.

Aerospace Industry

The aerospace sector harnesses 3D printing to produce lightweight yet durable components, such as turbine blades and fuel nozzles. This technology enables complex internal structures, reduces material waste, and enhances overall aircraft performance.

Fashion and Design Industry

Designers leverage 3D printing to bring their unique and intricate creations to life. From avant-garde fashion pieces to customizable accessories, the fashion industry benefits from the flexibility and creativity offered by additive manufacturing.

Education and Research

In educational institutions, 3D printers are used to enhance STEM education by allowing students to visualize complex concepts and create tangible models. Researchers utilize 3D printing to develop prototypes, conduct experiments, and explore new possibilities in various scientific fields.

Future Trends and Advancements in 3D Printing

The world of 3D printing is constantly evolving, and several exciting trends and advancements are on the horizon:

Bioprinting and Organ Manufacturing

Scientists and researchers are making significant progress in the field of bioprinting, aiming to print functional human tissues and even complete organs. This breakthrough could potentially revolutionize the healthcare industry, enabling organ transplantation without the need for donors.

Large-Scale 3D Printing

Advancements in technology are paving the way for larger and faster 3D printers capable of producing full-scale buildings and infrastructure. This has the potential to disrupt the construction industry, offering cost-effective and sustainable construction methods.

Integration with Artificial Intelligence

The combination of 3D printing with artificial intelligence algorithms allows for enhanced design optimization, material selection, and process automation. AI can analyze complex data sets to generate optimized structures and improve overall efficiency in additive manufacturing.

Sustainability and Recyclability

As environmental concerns grow, the 3D printing industry is exploring ways to reduce waste and promote recycling. Researchers are developing new materials that are biodegradable and derived from sustainable sources, making additive manufacturing more environmentally friendly.

Conclusion: Embracing the Power of 3D Printing in Manufacturing

3D printing has ushered in a new era of manufacturing, unlocking endless possibilities for design, customization, and innovation. From its layer-by-layer additive process to the diverse applications in industries like automotive, healthcare, aerospace, fashion, and education, 3D printing continues to shape the future of manufacturing. With ongoing advancements and future trends, we can expect even more remarkable breakthroughs in this dynamic field.

FAQs

- How accurate are 3D printed objects?

3D printed objects can achieve high accuracy, with precision depending on various factors such as the printer type, resolution, and design complexity. However, it’s important to note that certain post-processing steps might be required to achieve the desired level of accuracy. - Can 3D printing replace traditional manufacturing methods?

While 3D printing offers numerous advantages, it is unlikely to replace traditional manufacturing methods entirely. Traditional methods still excel in high-volume production and certain specialized applications. However, additive manufacturing continues to complement and revolutionize various aspects of manufacturing. - Are there any safety concerns associated with 3D printing?

When operating 3D printers, it’s important to ensure proper ventilation, especially when using certain materials that may emit fumes. Additionally, some printers use high-powered lasers, so safety precautions should be followed to protect against laser hazards. - How long does it take to 3D print an object?

The printing time varies depending on factors such as the size, complexity, and resolution of the object, as well as the type of printer and material being used. Small objects might take a few hours, while larger and more intricate designs can take several days or even weeks. - Can 3D printers create functional end-use products?

Yes, 3D printers can produce functional end-use products, especially with advancements in materials and technologies. However, the suitability of 3D printing for specific applications depends on factors like material properties, required durability, and cost considerations.