What are the best TPU settings?

Printing with TPU (Thermoplastic Polyurethane) filament requires specific settings to account for its flexibility and unique printing characteristics. Here are the best TPU settings to optimize print quality and minimize common issues like stringing, warping, and poor adhesion:

1. Print Temperature

- Recommended Range: 210°C to 230°C (410°F to 446°F)

- Why It Helps: TPU requires slightly higher temperatures than PLA, but not as high as ABS. Printing within this range ensures proper extrusion and flow.

- Tip: Start at 220°C and adjust depending on the results. If you notice stringing, you can lower the temperature slightly.

2. Bed Temperature

- Recommended Range: 50°C to 60°C (122°F to 140°F)

- Why It Helps: TPU doesn’t require as high a bed temperature as other materials like ABS, but a heated bed helps improve adhesion and prevents warping.

- Tip: If you are printing with TPU on a glass bed, ensure the bed is clean, and you can use adhesion aids (like a glue stick or hairspray) for better first-layer adhesion.

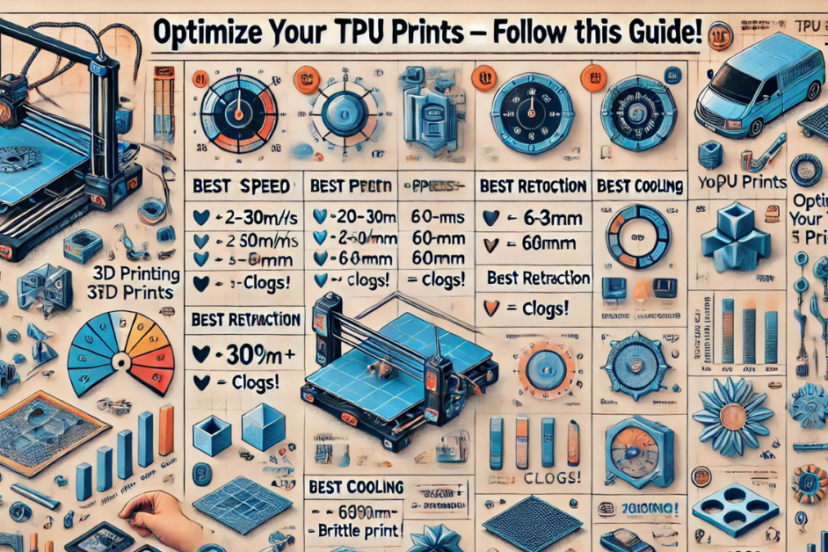

3. Print Speed

- Recommended Range: 20mm/s to 30mm/s (slower print speeds are better for TPU)

- Why It Helps: TPU is flexible and more prone to jams or extrusion issues when printed too quickly. Slower speeds help maintain smooth extrusion and prevent stringing.

- Tip: If you experience under-extrusion or poor layer bonding, slow the print speed further.

4. Retraction Settings

- Retraction Distance: 1mm to 3mm

- Retraction Speed: 20mm/s to 40mm/s

- Why It Helps: TPU is flexible, and retraction helps reduce stringing and oozing. However, too much retraction can lead to clogs. Start at 1mm for retraction distance and adjust accordingly.

- Tip: Make sure your extruder is properly calibrated, and consider reducing retraction distance for flexible filaments to avoid jamming.

5. Cooling Fans

- Recommended Cooling: 20% to 40%

- Why It Helps: TPU benefits from moderate cooling, especially on overhangs and small features. Too much cooling can cause warping or poor layer bonding, while too little cooling can lead to excessive stringing.

- Tip: Use cooling fans sparingly, particularly for the first few layers, and increase cooling as the print progresses.

6. Flow Rate

- Recommended Flow Rate: 95% to 105%

- Why It Helps: TPU can sometimes be under-extruded, especially if it’s too flexible for the printer setup. Adjusting the flow rate ensures a smooth, consistent extrusion.

- Tip: Start at 100% flow rate and adjust based on the appearance of your prints. If prints are under-extruded, slightly increase the flow rate.

7. Layer Height

- Recommended Layer Height: 0.2mm to 0.4mm

- Why It Helps: A larger layer height ensures better print quality, but keep it in the recommended range for TPU to ensure smooth layers and good bonding.

- Tip: For high-detail prints, you can use a smaller layer height, but avoid going too fine, as it may slow down the printing process without significant benefit.

8. Nozzle Size

- Recommended Nozzle Size: 0.4mm to 0.6mm

- Why It Helps: TPU works well with a standard 0.4mm nozzle, but if you are printing with thicker layers or faster prints, a 0.6mm nozzle can help reduce clogging and ensure smoother extrusion.

- Tip: Larger nozzles allow for faster printing but may result in less detail in fine prints.

9. Enable Z-Hop

- Why It Helps: Z-hop (lifting the nozzle during travel movements) prevents the nozzle from dragging across already printed areas, especially when printing with flexible filaments like TPU.

- How to Enable: In your slicer, enable the Z-hop option and set it to 0.2mm to 0.4mm.

- Benefit: This reduces stringing and improves print quality by preventing unwanted filament from being left behind during travel movements.

10. Use a Direct Drive Extruder (if possible)

- Why It Helps: TPU is flexible and can buckle or bend inside the extruder, leading to jams. A direct drive extruder is better suited for flexible filaments like TPU, as it minimizes the distance the filament travels before entering the hotend.

- Tip: If you’re using a Bowden extruder, you may want to reduce the retraction distance and speed to prevent TPU from jamming.

11. Print with a Brim or Raft (Optional)

- Why It Helps: TPU can sometimes struggle with adhesion on the print bed, especially for prints with a small contact area.

- How to Do It: Use a brim or raft to increase the contact area of the first few layers and ensure better adhesion.

- Benefit: This is particularly helpful for large or intricate prints to prevent warping or print failures.

Summary of Best TPU Settings:

- Print Temperature: 210°C to 230°C

- Bed Temperature: 50°C to 60°C

- Print Speed: 20mm/s to 30mm/s

- Retraction Distance: 1mm to 3mm, Retraction Speed: 20mm/s to 40mm

- Cooling Fans: 20% to 40%

- Flow Rate: 95% to 105%

- Layer Height: 0.2mm to 0.4mm

- Nozzle Size: 0.4mm to 0.6mm

- Z-Hop: Enable with 0.2mm to 0.4mm lift

- Extruder Type: Direct Drive (preferred for TPU)

By adjusting these settings based on your specific printer and TPU brand, you can achieve high-quality prints with TPU that are flexible, durable, and smooth. Remember that TPU is a flexible material, so printing slower and making slight adjustments will help ensure a successful print.