How does moisture affect filament quality?

Moisture can have a significant impact on the quality of 3D printing filament, especially for materials that are sensitive to humidity. When filament absorbs moisture from the air, it can lead to a variety of issues that affect both the printing process and the final print quality. Here’s a breakdown of how moisture can affect filament and its performance:

1. Poor Print Quality

- Bubbling and Popping: When filament absorbs moisture, it can cause water to turn into steam during extrusion. This leads to bubbling or popping sounds as the moisture evaporates. The result is inconsistent extrusion, which can cause print defects like holes, weak spots, or visible bubbles in the print.

- Sputtering or Hissing: Filament with absorbed moisture can produce inconsistent extrusion as the water evaporates. This leads to sputtering, hissing, or irregular extrusion that makes it difficult to achieve smooth, even layers.

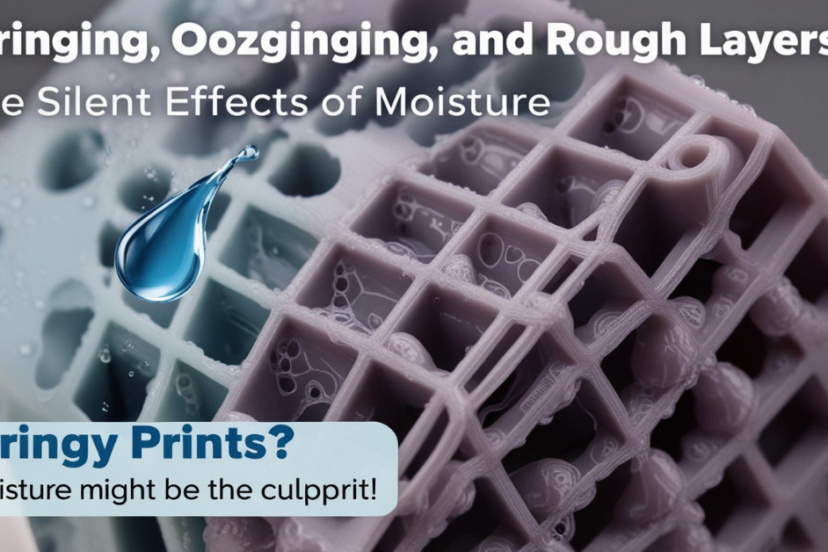

2. Stringing and Oozing

- Increased Stringing: Moisture can affect how filament flows through the extruder. Filament that is too wet may become more fluid than expected, causing it to ooze out of the nozzle even when it’s not supposed to. This results in stringing, where fine threads of filament are left between parts of the print.

- Worse Retraction: With moisture in the filament, the retraction process may not work properly. When the filament expands due to moisture, it doesn’t retract properly, leading to more oozing and stringing between parts of the print.

3. Weak or Brittle Prints

- Reduced Strength: Filament that has absorbed moisture may lose some of its mechanical properties. For example, Nylon and ABS can become brittle or weaker when moisture is present, leading to fragile prints that are more likely to break or deform.

- Impact on Layer Bonding: Moisture can disrupt the bond between layers of a print. This can lead to delamination or poor adhesion between layers, making the print more prone to breaking or failing under stress.

4. Inconsistent Extrusion

- Inconsistent Flow: Wet filament can cause inconsistent extrusion, leading to under-extrusion or over-extrusion. This happens because the moisture inside the filament can create pressure fluctuations in the extruder, making it harder to maintain a steady and controlled extrusion rate.

- Clogs: In some cases, if the filament is very moist, it can cause clogs in the nozzle as steam builds up and forces the filament to expand, potentially obstructing the flow of filament.

5. Color and Surface Finish Issues

- Surface Defects: Moisture can lead to defects in the surface finish of the print, such as rough textures or blemishes. As moisture evaporates during the printing process, it can cause surface bubbling and inconsistent finish.

- Color Changes: For certain filaments, like PLA, excessive moisture can lead to discoloration or dull finishes. This can affect aesthetic prints where the color consistency is important.

6. Increased Warping

- Warping Issues: Filament that has absorbed moisture can expand as it heats, which increases the likelihood of warping or the print lifting off the bed during printing, especially for materials like ABS or PETG. This can lead to failed prints or poor adhesion to the print bed.

Filaments Most Affected by Moisture:

- Nylon: Highly sensitive to moisture, it can absorb up to 10% of its weight in water, which significantly impacts its mechanical properties and print quality.

- TPU: Flexible filaments like TPU are also highly prone to moisture absorption, leading to issues like poor extrusion, stringing, and poor print quality.

- ABS: ABS is somewhat moisture-resistant but can still experience issues like warping and inconsistent extrusion if exposed to high humidity.

- PETG: PETG can absorb moisture and can suffer from stringing and poor adhesion when it is exposed to humidity.

- PVA: PVA (a water-soluble filament) is highly sensitive to moisture and will dissolve in the presence of water, rendering it unusable for prints.

- Polycarbonate: Polycarbonate filaments are also moisture-sensitive and will degrade in quality if stored improperly.

How to Prevent Moisture from Affecting Filament:

- Proper Storage: Store filament in airtight containers or vacuum-sealed bags with desiccants (silica gel) to absorb moisture. For long-term storage, use a filament dry box or a humidifier-controlled environment.

- Filament Drying: If your filament has absorbed moisture, dry it using a filament dryer or in an oven at a low temperature (around 40-50°C) for a few hours to remove the moisture.

- Use a Dry Box While Printing: Keep your filament in a dry box during printing to prevent it from reabsorbing moisture from the air.

- Store in a Cool, Dry Place: Ensure your filament is kept away from humid environments like bathrooms or kitchens.

Summary of How Moisture Affects Filament Quality:

- Print Defects: Moisture can cause bubbling, popping, stringing, and hissing, leading to poor print quality.

- Weak Prints: Wet filament can reduce the strength of your prints, making them brittle or prone to breaking.

- Inconsistent Extrusion: Moisture affects the flow of filament, causing under-extrusion, over-extrusion, or clogs.

- Surface Issues: Filament with moisture can result in poor surface finishes, including rough textures and discoloration.

- Warping: Moisture can increase the likelihood of warping, leading to print failure.

By taking proper precautions to store filament in dry, controlled conditions and drying filament before use, you can significantly improve print quality and reduce issues caused by moisture absorption.