Can Vacuum-Sealed Bags Be Used for Storing Filament While Printing?

Vacuum-sealed bags are an excellent storage solution for keeping filament dry and free from contaminants, but they are not ideal for storing filament while actively printing. Here’s why:

1. Accessing the Filament

- Why It’s a Concern: One of the main limitations of vacuum-sealed bags is that they need to be resealed every time you access the filament. This makes it impractical for use during active printing when you need continuous access to filament.

- Problem: When using vacuum-sealed bags, every time you open the bag to load filament into the printer, the bag loses its airtight seal. This can lead to moisture absorption once the seal is compromised, which defeats the purpose of storing the filament in a vacuum-sealed bag.

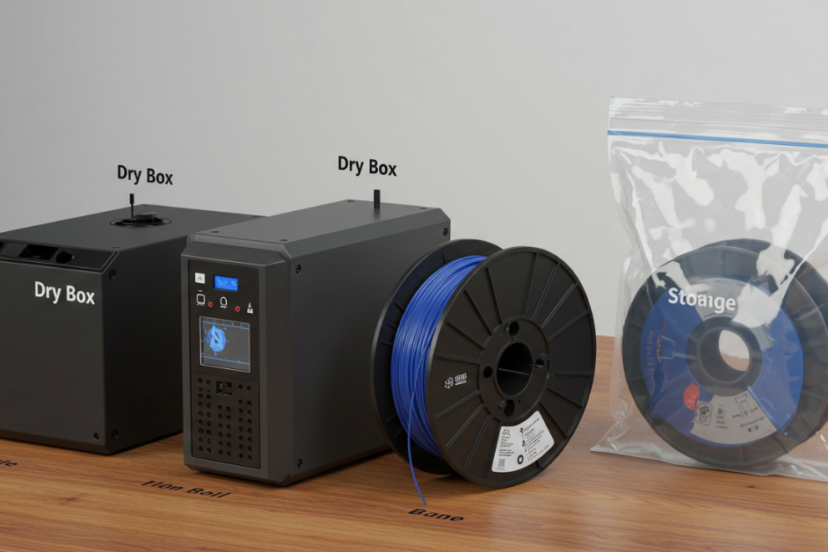

- Solution: Vacuum-sealed bags are better suited for long-term storage rather than active use. For ongoing printing, it’s more efficient to use dry boxes or spool holders that allow easy access to filament without compromising moisture control.

2. Inconvenience of Re-Sealing

- Why It’s a Concern: Every time you open a vacuum-sealed bag to use filament, you need to reseal it immediately after use to ensure it stays protected from moisture. If you’re printing frequently or switching between filament types, this can become a cumbersome and time-consuming process.

- Problem: The need to reseal the bag after every use introduces an extra step in the printing process, which can be impractical, especially for users who need to print multiple objects or switch filaments regularly.

- Solution: Filament dry boxes or spool racks with moisture control are much more convenient for active use since they allow you to keep filament accessible and protected simultaneously.

3. Difficulty with Feeding Filament During Printing

- Why It’s a Concern: Vacuum-sealed bags are not designed for active filament feeding. They are primarily made to store filament in a sealed environment to protect it from moisture.

- Problem: If you try to print directly from a vacuum-sealed bag, you would need to open the bag, remove the filament spool, and then manually feed the filament into the printer. This creates unnecessary interruptions and could cause filament tangling or snags while feeding into the extruder.

- Solution: Dry boxes are designed to store filament and allow it to be fed directly into the 3D printer without needing to open the container, making them more suitable for ongoing use.

4. Risk of Moisture Reabsorption

Why It’s a Concern: Once you open a vacuum-sealed bag, the filament is exposed to the surrounding environment. If the environment is humid, the filament will begin absorbing moisture again, which could affect the print quality.

Problem: If you don’t reseal the vacuum-sealed bag immediately after printing, the filament could absorb moisture, leading to issues like bubbling, weak adhesion, or stringing during future prints.

Solution: To prevent this, dry boxes and other airtight storage containers are more suitable for maintaining a controlled environment for filament that is in active use.

5. Limited Capacity for Continuous Printing

- Why It’s a Concern: Vacuum-sealed bags are not built for continuous access to filament. They are primarily designed to keep filament sealed in a moisture-free environment for long-term storage.

- Problem: For extended printing sessions, you would need to open the vacuum-sealed bag multiple times, which defeats the purpose of storing the filament in an airtight condition.

- Solution: Instead of using vacuum-sealed bags during printing, consider using filament dry boxes that are equipped with features like humidity control and spool holders to allow uninterrupted, continuous access.

6. Filament Spool Size Considerations

Why It’s a Concern: Vacuum-sealed bags are generally designed for smaller filament spools. Larger filament spools, particularly those above 1 kg, may not fit comfortably in vacuum-sealed bags without being over-compressed.

Problem: Over-compressing the filament spool could deform it, making it more difficult to use or feed into the 3D printer. Also, some vacuum-sealing bags may be too small for larger rolls, causing you to buy more bags for multiple spools.

Solution: Dry boxes or filament storage racks are designed to store larger spools more efficiently and offer easy access for continuous printing.

7. Vacuum-Sealed Bags Are Not Designed for Humidity Control During Printing

Why It’s a Concern: Vacuum-sealed bags do not actively control humidity during printing. While they can prevent moisture from entering the bag during storage, they don’t provide the same level of moisture control while the filament is in use.

Problem: Filament can still absorb moisture from the air once the bag is opened, especially in a high-humidity environment or if the bag is not resealed quickly. This can affect print quality.

Solution: Filament dry boxes with built-in humidity control are ideal for maintaining consistent moisture levels while printing, ensuring better print quality and performance.

Summary of Why Vacuum-Sealed Bags Are Not Ideal for Storing Filament While Printing:

- Inconvenient Access: Vacuum-sealed bags require resealing after every use, making them impractical for active printing.

- Difficulty Feeding Filament: Vacuum bags aren’t designed to allow easy, continuous feeding of filament into the 3D printer.

- Risk of Moisture Reabsorption: Once opened, the filament can absorb moisture from the environment, which can degrade print quality.

- Limited Capacity for Continuous Use: Vacuum-sealed bags are designed for long-term storage, not for regular or ongoing access during printing.

- Filament Size Issues: Large filament spools may not fit well in vacuum-sealed bags, making them less practical for certain spool sizes.

- Lack of Active Humidity Control: Vacuum-sealing provides no active control of humidity during the printing process, unlike dry boxes or humidity-controlled containers.

Conclusion:

While vacuum-sealed bags are great for long-term filament storage, they are not ideal for active use during printing. For printing purposes, it’s better to use dry boxes or spool racks that allow easy access to filament while maintaining a moisture-controlled environment. Vacuum-sealing is best reserved for storing unused filament for long periods, especially when the goal is to protect the material from moisture and degradation.