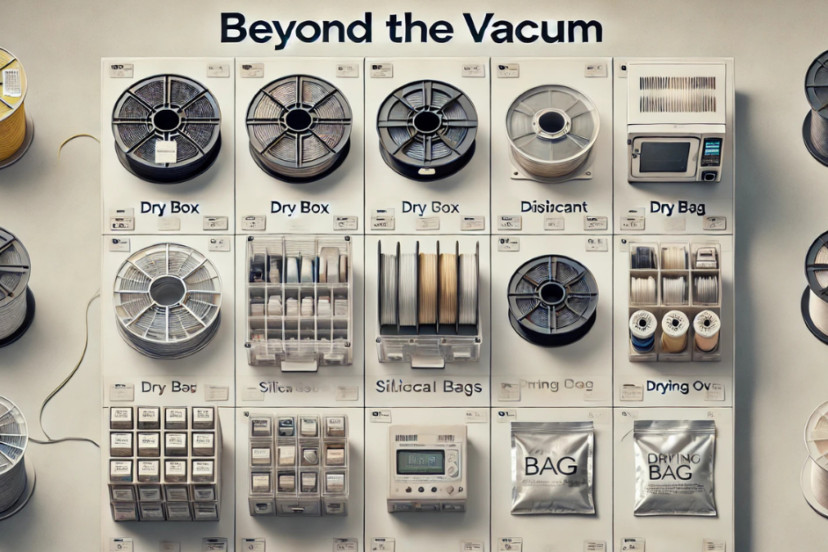

Are There Alternatives to Vacuum-Sealing for High-Quality Filament Storage?

While vacuum-sealing is one of the most effective methods for storing 3D filament and protecting it from moisture and environmental damage, it is not the only option available. Depending on your needs, budget, and convenience, there are several alternatives to vacuum-sealing that can also ensure the long-term quality and stability of your filament. Let’s explore some of the most popular alternatives to vacuum-sealing for high-quality filament storage

1. Filament Dry Boxes

What It Is:

- A filament dry box is a sealed container designed to control the humidity around stored filament. Many dry boxes are equipped with desiccants, heating elements, and humidity sensors to actively monitor and maintain a low-humidity environment for filament storage.

Why It Works for Filament Storage:

- Filament dry boxes are specifically designed to prevent moisture absorption by keeping the filament in a low-humidity environment. This is particularly useful for moisture-sensitive filaments like Nylon, TPU, and ABS, which can degrade rapidly if exposed to moisture.

How It Works:

- A filament dry box either uses desiccant packets to absorb moisture or active heating elements to circulate dry air within the box. Some models even have built-in humidity controls to maintain the ideal moisture level for filament storage.

Benefit:

- Dry boxes are great for active use because they allow easy access to the filament without having to open and reseal bags. They provide continuous moisture protection and are excellent for filament types that need consistent moisture control.

Limitations:

- Dry boxes can be more expensive than vacuum-sealing, especially those with advanced features like humidity control or heating elements. They can also be bulkier, taking up more storage space.

2. Airtight Storage Containers with Desiccants

What It Is:

- Airtight containers are sealed boxes or bins designed to keep moisture and air out. These containers can be paired with desiccants (such as silica gel) to absorb any residual moisture inside the container.

Why It Works for Filament Storage:

- Airtight containers provide basic moisture protection by sealing the filament away from humidity and contaminants. When combined with desiccants, they can maintain a low-humidity environment inside the container, making them effective for storing filament.

How It Works:

- Place the filament spool inside an airtight container and add desiccant packets to absorb moisture. For optimal moisture control, you should also use silica gel packets that can be replaced or recharged periodically.

Benefit:

- Airtight containers are cost-effective and easy to use. They provide basic protection for filament and are more accessible than vacuum-sealing bags. These containers are also stackable, making them space-efficient for storing multiple spools.

Limitations:

- While effective at preventing moisture, airtight containers are not as effective as vacuum-sealing at removing air from the environment. Over time, desiccants may need to be replaced, and humidity levels can fluctuate, leading to potential moisture exposure.

3. Spool Holders with Desiccant Compartments

What It Is:

- Spool holders are devices that hold filament spools during printing. Some advanced spool holders come with built-in desiccant compartments to absorb moisture and help maintain filament quality.

Why It Works for Filament Storage:

- Spool holders with desiccant compartments are useful for short-term filament storage while actively printing. They ensure that the filament remains dry as it is being fed into the printer, particularly for moisture-sensitive filaments.

How It Works:

- These holders usually have small compartments for desiccants, which keep moisture levels low around the filament. Some holders even have built-in humidity sensors to monitor the filament’s environment in real-time.

Benefit:

- Spool holders with desiccants are easy to use and provide active moisture protection while the filament is in use. They are especially beneficial for filaments that are used regularly, ensuring they stay dry throughout the printing process.

Limitations:

- Spool holders with desiccants are more suitable for short-term storage or while actively printing. They are less effective for long-term storage compared to vacuum-sealing or dry boxes, as they don’t offer complete airtight environments.

4. Silica Gel Bags or Pouches

What It Is:

- Silica gel bags are small, breathable pouches filled with silica gel (a desiccant) that absorbs moisture from the surrounding environment. These bags can be placed inside storage containers or vacuum-sealed bags to keep filament dry.

Why It Works for Filament Storage:

- Silica gel is a highly effective moisture absorber that helps prevent filament from absorbing ambient moisture, which can cause bubbling and extrusion issues. By using silica gel bags, you can maintain the quality of your filament without needing specialized storage containers.

How It Works:

- Simply place the silica gel bags in the same container as the filament, or add them to your vacuum-sealed bag. The silica gel will absorb any moisture in the air, keeping the filament dry. Some silica gel bags can be recharged by heating them in an oven.

Benefit:

- Silica gel bags are cheap, easy to use, and provide continuous moisture protection. They are highly effective when used in combination with other storage methods like airtight containers or vacuum-sealed bags.

Limitations:

- Silica gel bags need to be recharged or replaced periodically, and they are not as highly effective as more controlled methods, like dry boxes or vacuum-sealing, for long-term storage.

5. Active Filament Drying Systems

What It Is:

- Active filament drying systems are machines designed to dry filament before printing. They typically include a temperature-controlled chamber that circulates dry air to remove moisture from filament before printing.

Why It Works for Filament Storage:

- While these systems are primarily used for drying filament, they can also be used to re-dry filament after it has been exposed to moisture. Many drying systems include temperature controls to prevent the filament from being exposed to too much heat, which could cause damage.

How It Works:

- Filament spools are placed inside a drying chamber, where the air is circulated and heated to help remove absorbed moisture. The system typically monitors the filament’s moisture content and stops when it reaches the desired dryness level.

Benefit:

- Active drying systems are ideal for restoring moisture-sensitive filaments like Nylon or TPU that have absorbed moisture. They ensure that the filament is dry and ready to print, offering an effective solution for immediate use.

Limitations:

- These systems are typically more expensive than other storage methods and are best suited for filament that has already absorbed moisture. They are not intended for long-term storage and will not prevent moisture from entering the filament during long periods of storage.

6. Climate-Controlled Storage Rooms

What It Is:

- Climate-controlled storage refers to keeping filament in a room or space with carefully regulated temperature and humidity levels to prevent degradation and moisture absorption.

Why It Works for Filament Storage:

- Climate-controlled rooms provide the ultimate control over temperature and humidity, creating a consistent storage environment for filament. This method is especially useful for large filament collections or in areas with high humidity.

How It Works:

A climate-controlled room typically includes air conditioning, humidifiers, or dehumidifiers to maintain the ideal humidity level for filament storage. You can store filament in airtight containers, spool holders, or dry boxes within this environment for added protection.

Benefit:

- Climate-controlled rooms provide the best possible storage conditions for filament, especially in regions with fluctuating humidity levels. This option is ideal for users with large filament collections or those who need to maintain optimal storage conditions for extended periods.

Limitations:

- This method is typically more expensive and requires a dedicated space to control temperature and humidity levels. It may not be practical for all users, especially those with limited space or budget.

Summary of Alternatives to Vacuum-Sealing for High-Quality Filament Storage:

| Method | Effectiveness | Cost | Best For |

|---|---|---|---|

| Filament Dry Boxes | Excellent for active use, continuous moisture control | Medium to High | Long-term and active use |

| Airtight Containers | Good for short-term storage, cost-effective | Low to Medium | Basic moisture protection |

| Spool Holders with Desiccants | Short-term use with active moisture protection | Medium | Active use, printing |

| Silica Gel Bags | Cheap, effective for moisture absorption | Low | Short-term moisture control |

| Active Filament Drying Systems | Effective for drying filament before use | High | Restoring moisture-sensitive filaments |

| Climate-Controlled Rooms | Ultimate moisture and temperature control | High | Large filament collections |

Conclusion:

While vacuum-sealing is one of the most effective methods for long-term filament storage, there are several viable alternatives depending on your needs. Filament dry boxes provide excellent moisture control for active use, while airtight containers and silica gel bags are cost-effective solutions for short-term storage. Active filament drying systems are great for re-drying filament that has absorbed moisture, and climate-controlled rooms offer the best solution for large collections or areas with high humidity. Each method has its advantages, so consider your storage space, budget, and filament needs when selecting the best storage method for your filament.