Can I print Nylon without a heated bed?

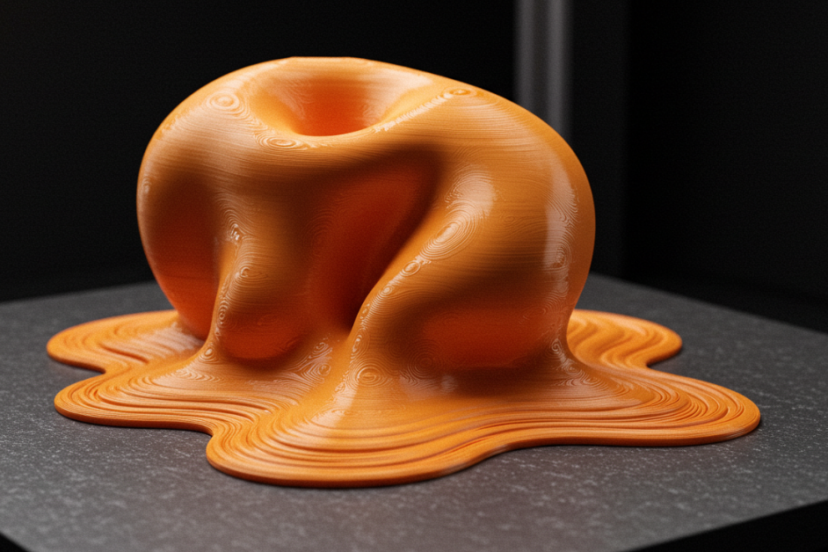

While it is technically possible to print Nylon without a heated bed, it is not recommended for most cases. Nylon is highly prone to warping and has a strong tendency to shrink as it cools, which can lead to adhesion issues, especially on the edges of the print. A heated bed plays a crucial role in helping the filament stay attached to the print bed and reducing the risk of warping.

However, if you must print without a heated bed, here are a few tips to help improve your chances of a successful print:

1. Use an Adhesion Aid

- Glue Stick, Hairspray, or PEI Sheets: Applying a thin layer of glue stick, hairspray, or using a PEI (Polyetherimide) sheet can improve bed adhesion and help the Nylon stay in place while printing.

- Why It Helps: These adhesion aids create a sticky surface that allows the first layer to bond better with the print bed, reducing the risk of lifting and warping.

2. Print at a Slower Speed

- Why It Helps: Printing at slower speeds, especially for the first few layers, can help with better adhesion and reduce the chances of the material warping or lifting.

- How to Do It: Lower the first layer print speed to around 30% of your regular speed to give the filament more time to adhere to the bed.

3. Use a Brim or Raft

- Why It Helps: Adding a brim (extra lines around the base of the print) or a raft (a thick base layer) can increase the surface area of the print, helping the first few layers stick better to the bed and reduce the chances of warping.

- How to Do It: In your slicer settings, enable a brim or raft for larger prints or prints with sharp corners.

4. Maintain a Consistent Environment

- Why It Helps: Temperature fluctuations or drafts can cause Nylon to warp, even without a heated bed. Keeping your printing area warm and free from drafts can help improve adhesion.

- How to Do It: If possible, print in an enclosed area to maintain a consistent temperature around the print.

5. Use a High-Quality Print Surface

- Why It Helps: A high-quality surface, such as a PEI sheet, glass bed, or BuildTak, can improve adhesion and help reduce warping.

- How to Do It: Ensure your print surface is clean and level before starting the print to maximize adhesion.

Conclusion

While you can print Nylon without a heated bed, the results may not be as consistent or reliable as when using a heated bed. A heated bed helps prevent warping, improves adhesion, and allows for better print quality. If you don’t have a heated bed, follow the tips above to improve your chances of a successful print. However, for optimal results with Nylon, using a heated bed is strongly recommended.