Top 10 Innovations in 4D Printing: Smart Materials That Adapt to the Future

Imagine a world where your shoes morph to fit your feet perfectly when it rains, or a medical implant grows with your body. Sounds like sci-fi, right? Well, welcome to the reality of 4D printing! This isn’t just about stacking layers like your trusty 3D printer—it’s about creating objects that evolve over time, reacting to the world around them. As a tech enthusiast who’s spent way too many hours tinkering with printers, I’m here to walk you through the top 10 innovations in 4D printing that are shaping our future. Ready to see how smart materials are rewriting the rulebook? Let’s jump in!

What is 4D Printing?

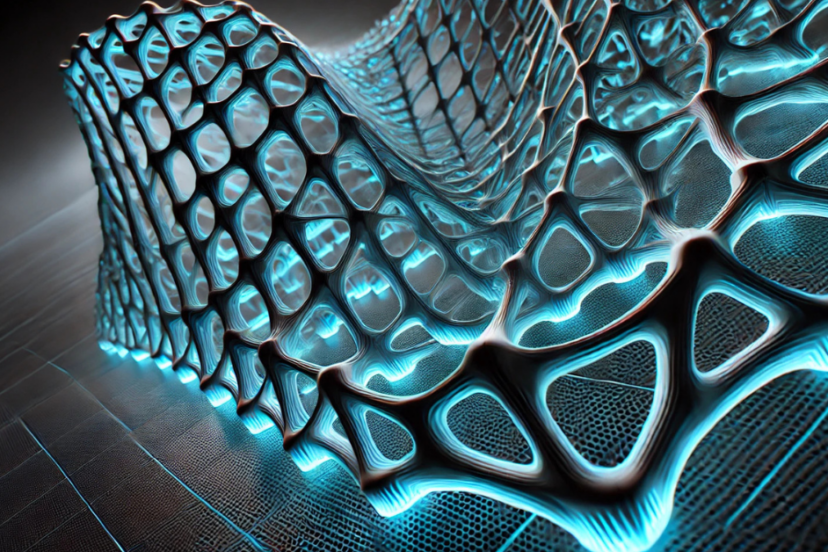

So, what’s the deal with 4D printing? Picture this: you take a 3D printer, feed it some seriously clever materials, and voilà—the printed object doesn’t just sit there. It changes shape or function when triggered by stuff like heat, water, or light. That “time” factor? That’s the fourth dimension. Think of it as 3D printing’s cooler, more dynamic cousin. While 3D printing gives us static objects, 4D printing hands us living, breathing designs that adapt. Pretty mind-blowing, huh?

Why 4D Printing Matters

Why should you care? Because 4D printing is shaking up industries faster than you can say “filament.” From medicine to aerospace, it’s solving problems we didn’t even know we had. Need a stent that expands inside a patient? Done. Want a plane part that adjusts mid-flight? Yep, that’s on the table too. It’s not just about cool tricks—it’s about efficiency, sustainability, and pushing boundaries. Trust me, this is one tech trend you don’t want to sleep on.

Top 10 Innovations in 4D Printing

Here’s the juicy part: the top 10 breakthroughs in 4D printing that are turning heads and sparking ideas. These aren’t pie-in-the-sky concepts—they’re real innovations from real brands. Let’s break them down.

1. Stratasys J850: Self-Evolving Structures

Stratasys is a titan in the printing world, and their J850 printer is a 4D printing beast. Using PolyJet materials, it creates objects that twist and fold when heated. Imagine printing a flat sheet that turns into a cube—no assembly required! It’s perfect for prototyping dynamic designs, and I’ve seen it in action—pure wizardry.

2. HP Multi Jet Fusion: Adaptive Industrial Parts

HP’s Multi Jet Fusion (MJF) isn’t just for 3D—it’s stepping into 4D territory with smart polymers. These parts shift under pressure or temperature, making them ideal for industrial applications. Think self-adjusting gears or ducts that expand with airflow. HP’s precision makes it a game-changer for manufacturers.

3. MIT’s Self-Assembly Lab: Programmable Carbon Fiber

MIT’s Self-Assembly Lab, led by Skylar Tibbits, is where 4D printing was born. Their work with programmable carbon fiber—think flexible, heat-responsive sheets—has teamed up with brands like Carbitex. The result? Materials that curl or stiffen on demand, perfect for adaptive clothing or robotics.

4. Autodesk’s Research: Software-Driven 4D Design

Autodesk isn’t just about printers—they’re crafting the brains behind 4D printing. Their software lets designers simulate how objects will transform over time. Paired with printers like the Stratasys J850, it’s a dream team for creating everything from self-folding furniture to responsive architecture.

5. Sigma-Aldrich Hydrogels: Moisture-Responsive Implants

Sigma-Aldrich’s hydrogels are a 4D printing gem for medicine. These squishy, water-loving materials swell or shrink when wet, making them ideal for implants that adapt inside the body. Picture a stent that grows with a child—Sigma-Aldrich is making it happen.

6. SMP Technologies: Shape Memory Polymers for Aerospace

SMP Technologies specializes in shape memory polymers (SMPs) that snap back to their original form when heated. Used with printers like the HP MJF, these materials are soaring into aerospace—think wings that adjust mid-flight or panels that repair themselves. Lightweight and tough? Yes, please!

7. REGENHU BioPrinters: 4D Bioprinting for Tissues

REGENHU’s bioprinting tech takes 4D printing into living territory. Their printers use smart biomaterials that evolve post-printing, like scaffolds that guide tissue growth. It’s a leap toward printing organs that adapt and heal—straight out of a sci-fi novel, but very real.

8. Poietis Skin Printing: Self-Adapting Tissue

Poietis is redefining bioprinting with 4D-printed skin that responds to its environment. Using laser-assisted tech, they’ve created tissue that adjusts to moisture or heat—think burn grafts that evolve as they heal. It’s a lifesaver, and it’s happening now.

9. Airbus Programmable Inlets: Dynamic Aerospace Parts

Airbus, partnering with MIT, has developed 4D-printed programmable inlets for jet engines. Made with carbon fiber and smart polymers, these parts adjust airflow automatically. Less fuel waste, better performance—aviation just got a whole lot smarter.

10. NASA Space Chain Mail: Flexible Space Fabrics

NASA’s 4D-printed Space Chain Mail is out of this world—literally. This metallic fabric, printed with smart alloys, shifts between rigid and flexible states. It’s designed for spacesuits and antennas, adapting to the harshness of space. Who wouldn’t want to wear that?

How These Innovations Work

So, how do these wonders happen? It’s all about smart materials—think of them as the superheroes of 4D printing. Shape memory polymers, hydrogels, and alloys react to stimuli like heat, water, or pressure. Printers like the Stratasys J850 or HP MJF lay down these materials in precise patterns, embedding instructions for change. It’s like planting a seed that knows how to grow into a tree—except it’s a bracket or a bone scaffold. Cool, right?

Real-World Applications

Where’s this tech popping up? Everywhere! In medicine, 4D printing’s crafting stents and drug-delivery systems that adapt inside you. Aerospace is using it for self-tuning parts, while fashion’s dreaming up clothes that shift with the weather. Even construction’s eyeing self-assembling structures. It’s like giving objects a brain—suddenly, they’re working with us, not just for us.

Challenges Ahead

But it’s not all smooth sailing. 4D printing’s still young—materials are pricey, and designing for “time” is tricky. Scaling it up for mass production? That’s a puzzle we’re still solving. And don’t get me started on the learning curve—mastering this takes patience. Still, every big leap starts with a stumble, right?

The Future of 4D Printing

What’s next? I’d bet on smarter materials and faster printers. Imagine homes that rebuild themselves after storms or cars that tweak their shape for speed. With brands like Stratasys, HP, and NASA pushing the envelope, 4D printing could be as common as 3D printing in a decade. Are you ready for a world where everything adapts?

Conclusion

There you have it—ten jaw-dropping innovations in 4D printing that prove the future’s already here. From Stratasys’s self-folding marvels to NASA’s space fabrics, smart materials are rewriting what’s possible. As someone who geeks out over printers, I can’t wait to see where this tech takes us. What do you think—got a favorite from the list? Drop your thoughts below and let’s geek out together!

FAQs

- What’s the difference between 3D and 4D printing?

3D printing creates static objects, while 4D printing adds time—objects change shape or function after printing using smart materials. - Can I buy a 4D printer for home use?

Not quite yet! Most 4D printing tech, like the Stratasys J850, is industrial-grade, but consumer versions might pop up soon. - Are 4D-printed objects safe for medical use?

Yes, innovations like Sigma-Aldrich hydrogels and REGENHU bioprinting are designed with biocompatibility in mind—pretty life-changing stuff! - How expensive is 4D printing compared to 3D printing?

It’s pricier due to specialized materials and tech, but costs are dropping as adoption grows—think early 3D printing vibes. - What’s the wildest 4D printing idea out there?

NASA’s Space Chain Mail takes the cake—flexible metal fabrics for space? That’s next-level cool!