How can I improve print adhesion?

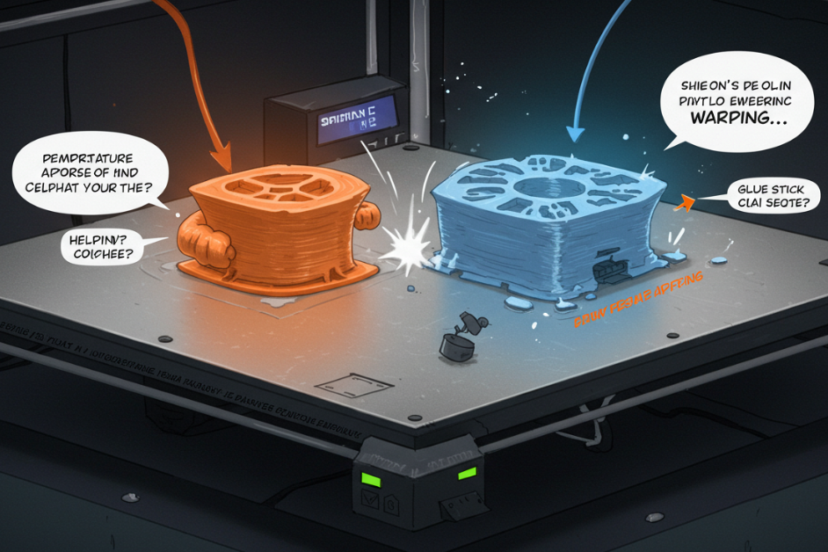

Improving print adhesion is crucial for ensuring that your 3D prints stick properly to the print bed, especially during the first few layers. Poor adhesion can lead to warping, shifting, or even print failure. Here are several strategies to help you improve print adhesion:

1. Level the Print Bed

- Why It Helps: A properly leveled bed ensures that the nozzle is at the correct distance from the bed across the entire print area. If the bed is too high or too low, the filament will not adhere properly to the bed.

- How to Do It:

- Manual leveling: Use a piece of paper or a bed leveling tool to adjust the bed at various points (corners and center) so that there is a slight resistance when the nozzle is at the proper height.

- Auto-bed leveling: If your printer has auto-bed leveling, use that feature to ensure the bed is correctly calibrated.

- Benefit: Ensures even first-layer adhesion, reducing the chances of warping or shifting.

2. Increase the Bed Temperature

- Why It Helps: A heated bed improves adhesion, especially for materials that tend to warp, like ABS and PETG. The heat helps the filament bond better to the bed, especially in the first few layers.

- How to Do It:

- PLA: Set the bed temperature to around 50°C to 60°C.

- ABS: Set the bed temperature to 90°C to 110°C.

- PETG: Set the bed temperature to 70°C to 80°C.

- Benefit: A warm bed ensures the first layers stick better, especially for materials with a tendency to warp.

3. Use Adhesion Aids (Glue Stick, Hairspray, etc.)

- Why It Helps: Adhesion aids can significantly improve the bond between the print and the bed, especially for filaments that struggle with adhesion.

- How to Do It:

- Glue Stick: Apply a thin, even layer of a glue stick on the print bed. This works well for PLA and other common filaments.

- Hairspray: Spray a light coat of hairspray on the bed (ensure it’s an even, thin layer). This is commonly used for ABS and PLA.

- Blue Painter’s Tape: For certain materials like PLA, you can apply blue painter’s tape to the bed to improve adhesion.

- PEI Sheets: Use a PEI sheet on your bed, which provides great adhesion for a variety of filaments and is reusable.

- Benefit: These materials create a better surface for the filament to adhere to and can help prevent warping.

4. Use a Brim or Raft

- Why It Helps: A brim or raft adds extra surface area for the print to adhere to, especially useful for prints with a small surface area or materials prone to warping.

- How to Do It:

- Brim: Adds several extra lines around your print to increase the adhesion area on the print bed.

- Raft: A raft creates a foundation layer beneath your print, ensuring solid adhesion even for materials with poor bed adhesion.

- Benefit: A brim or raft helps reduce the chances of the print detaching from the bed during printing, especially for larger prints or filaments prone to warping.

5. Adjust First Layer Settings

- Why It Helps: The first layer is critical for the overall success of the print. Ensuring it adheres well to the bed is essential to prevent problems later in the print.

- How to Do It:

- Slow down the first layer print speed: Reduce the first layer print speed to 50% of the regular speed to give the filament more time to adhere properly.

- Increase first layer height: Set the first layer height to 0.3mm or slightly more. This ensures the filament is extruded more evenly and makes better contact with the bed.

- Increase first layer extrusion: Increase the extrusion width or flow rate for the first layer to ensure a solid bond.

- Benefit: These settings give the first layer the best chance of sticking to the bed, preventing warping and failed prints.

6. Use the Right Print Surface

- Why It Helps: Some bed surfaces work better with certain filaments, so choosing the right surface material for your print is important for good adhesion.

- How to Do It:

- Glass Bed: A smooth glass bed provides a very flat surface but may need adhesion aids (like glue or hairspray) for certain filaments like ABS or PETG.

- PEI (Polyetherimide) Sheets: PEI sheets provide excellent adhesion for most filaments (PLA, PETG, ABS) without the need for additional adhesives.

- BuildTak or Magigoo: These are adhesive surfaces or sprays designed to improve adhesion for a variety of materials.

- Benefit: Choosing the right print surface material ensures that the filament sticks properly and reduces the chance of warping or failure.

7. Control Environmental Factors (Enclosures)

- Why It Helps: Drafts and temperature fluctuations can negatively affect adhesion, especially for filaments like ABS that are more prone to warping.

- How to Do It:

- Use a 3D printer enclosure to control the ambient temperature and prevent drafts, especially when printing with materials that require high bed temperatures.

- Keep the printer in a temperature-controlled room with consistent temperature and low air movement.

- Benefit: Environmental control ensures that the print has a stable temperature throughout the printing process, which is especially important for materials like ABS.

8. Use the Right Filament for the Job

- Why It Helps: Some filaments naturally have better adhesion to the bed than others.

- How to Do It:

- PLA: Known for its excellent adhesion and ease of use, PLA typically sticks well to most print surfaces without needing additional adhesives.

- ABS: Can warp easily, so use a heated bed and adhesion aids such as glue stick or hairspray to improve adhesion.

- PETG: PETG is more forgiving with adhesion but can benefit from a heated bed and the right print surface, like PEI.

- Benefit: Choosing the right filament with good bed adhesion properties helps avoid issues right from the start.

9. Keep the Print Bed Clean

- Why It Helps: Dirt, oil, or residue on the bed can prevent proper adhesion and lead to failed prints.

- How to Do It:

- Clean the print bed with isopropyl alcohol or mild soap and water to remove any contaminants.

- Avoid touching the bed with your hands to keep oils from your fingers from affecting adhesion.

- Benefit: A clean print surface provides a better surface for the filament to stick, reducing the chances of adhesion problems.

Summary:

To improve print adhesion, start by leveling the bed, adjusting temperature settings, and ensuring the first layer has proper settings. Using adhesion aids like glue stick, hairspray, or a PEI sheet can significantly help, and employing a brim or raft can be beneficial for difficult prints. Make sure your printer is in a stable environment, use the right filament for your print, and keep the bed clean. By optimizing these factors, you can achieve better adhesion and more successful prints.