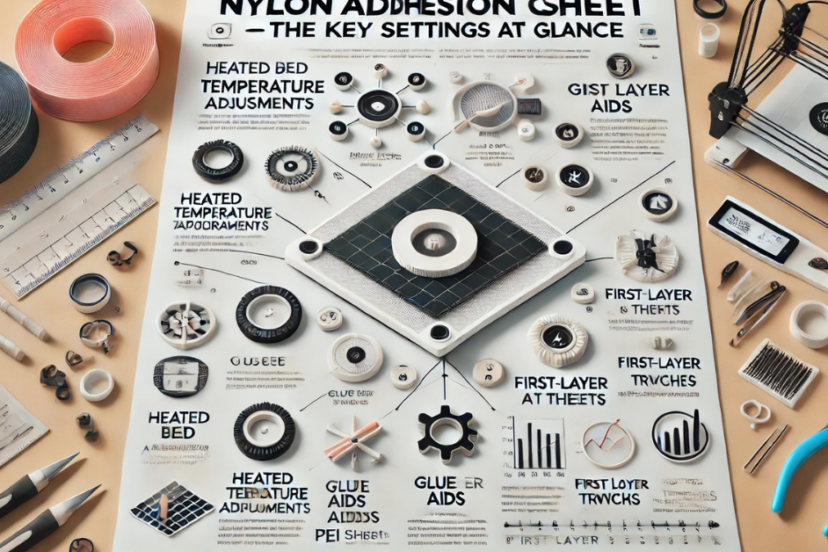

How can I improve Nylon adhesion?

Improving adhesion for Nylon filament can be challenging due to its tendency to warp and its low adhesion to print beds. However, there are several strategies you can use to enhance Nylon adhesion and ensure successful prints:

1. Use a Heated Print Bed

- Why It Helps: A heated bed keeps the first few layers of Nylon at a stable temperature, reducing warping and improving adhesion.

- How to Do It: Set your heated bed to 70°C to 90°C (158°F to 194°F), depending on the specific type of Nylon you are using. For better adhesion, higher temperatures work best.

2. Apply Adhesion Aids (Glue Stick, Hairspray, or PEI Sheet)

- Why It Helps: Adhesion aids like glue stick, hairspray, or a PEI (Polyetherimide) sheet create a tacky surface that helps Nylon stick better to the print bed.

- How to Do It:

- Glue Stick: Apply a thin, even layer of glue stick to the print bed before printing.

- Hairspray: Lightly spray a thin coat of hairspray on the print bed. Make sure to apply it in a well-ventilated area.

- PEI Sheet: PEI sheets are known for excellent adhesion properties and can be directly attached to the print bed for reliable results.

3. Use a Print Surface with High Adhesion

- Why It Helps: Some print surfaces offer better adhesion for Nylon than others, helping to ensure a strong first layer.

- How to Do It: Use build surfaces designed for Nylon, such as BuildTak, PEI sheets, or Kapton tape. These surfaces provide better grip for the first layer and help reduce warping.

4. Enclose the Printer

- Why It Helps: Nylon is prone to warping due to temperature fluctuations, so printing in an enclosed environment helps maintain a stable temperature and prevents drafts from affecting your print.

- How to Do It: Use a 3D printer enclosure or create a DIY enclosure around your printer to maintain a consistent, warm environment.

5. Increase First Layer Settings

- Why It Helps: Adjusting your first layer settings allows the filament to bond better to the bed and helps compensate for slight misalignment.

- How to Do It:

- First Layer Height: Increase the first layer height slightly to make the first layer thicker, giving more surface contact and improving adhesion.

- First Layer Speed: Reduce the print speed for the first layer to allow the filament more time to adhere to the print bed.

- First Layer Temperature: Increase the extrusion temperature for the first layer (around 10°C higher than the printing temperature) to help it stick better to the bed.

6. Use a Brim or Raft

- Why It Helps: A brim or raft increases the surface area of the first few layers, helping the print adhere better and preventing warping.

- How to Do It:

- Brim: Add a few extra lines around the base of your print (usually 5-10 lines) to provide additional surface area for adhesion.

- Raft: Print a raft under the model. A raft consists of a few layers of material that help with adhesion and improve bed contact.

7. Dry the Filament

- Why It Helps: Nylon is highly hygroscopic, meaning it absorbs moisture from the air. Moisture in the filament can cause poor adhesion and print quality. Drying the filament before printing ensures better results.

- How to Do It: Dry your Nylon filament in a filament dryer, oven (at 70°C-75°C for 4-6 hours), or food dehydrator before printing to remove excess moisture.

8. Use a Stronger Adhesive Layer (For Nylon Composite Filaments)

- Why It Helps: For composite Nylon filaments (e.g., those with carbon fiber or glass fiber), adhesion can be more challenging. Applying a stronger adhesive layer can improve adhesion to the print bed.

- How to Do It: Consider using Kapton tape or 3M Scotch-Weld adhesives for tougher composite filaments to improve adhesion.

9. Level Your Print Bed Properly

- Why It Helps: An improperly leveled print bed can cause uneven first layer adhesion, leading to warping or poor adhesion.

- How to Do It: Ensure your print bed is level before printing. Use your printer’s bed leveling function or manually adjust it to make sure it’s even across the entire surface.

Conclusion

Improving Nylon adhesion requires a combination of proper bed preparation, environmental control, and print settings. Using a heated bed, applying adhesion aids, and ensuring proper moisture control can significantly improve your print quality. Additionally, using an enclosure and adjusting first layer settings will help ensure better adhesion and reduce the risk of warping and failed prints.