Can TPU be printed on a glass bed?

Yes, TPU (Thermoplastic Polyurethane) can be printed on a glass bed, but there are some important considerations to ensure good adhesion and successful prints. Glass beds are commonly used because they provide a smooth and flat surface, which helps achieve consistent first-layer adhesion. However, TPU is a flexible material that can sometimes have trouble sticking to a glass surface, especially during the first few layers. Here’s how you can successfully print TPU on a glass bed:

Tips for Printing TPU on a Glass Bed:

1. Use a Heated Bed

- Why It Helps: A heated bed helps improve adhesion, especially with flexible materials like TPU. A heated bed helps the filament adhere to the glass by preventing the edges from lifting during printing.

- Recommended Temperature: Set the heated bed temperature to around 50°C to 60°C. TPU doesn’t require as high a temperature as some other filaments, but the heated bed helps ensure better adhesion to the glass.

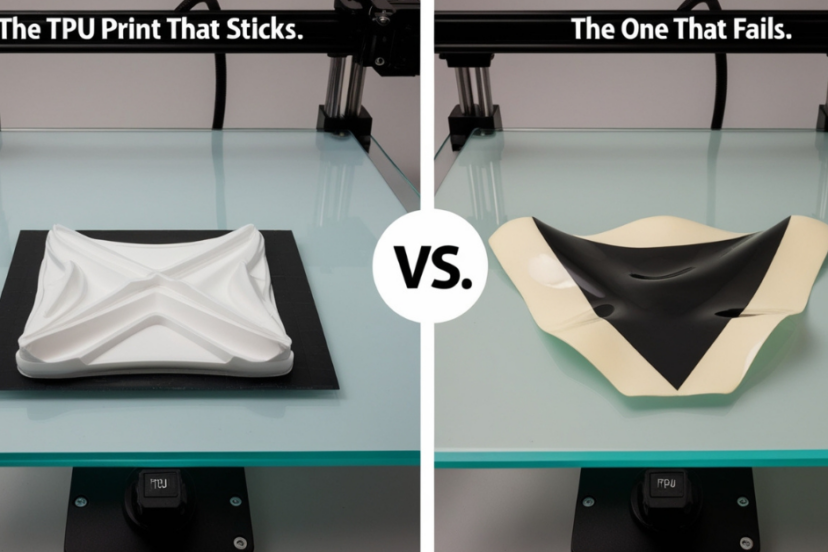

2. Apply an Adhesion Aid (Glue Stick, Hairspray, or PEI Sheet)

Why It Helps: TPU can sometimes struggle to stick to a glass bed without additional adhesion support. Applying a thin layer of glue stick or hairspray can provide a better surface for the first layer to adhere to.

- How to Do It:

- Apply a glue stick or a light coat of hairspray to the glass bed before starting the print.

- Alternatively, you can use a PEI sheet or other adhesive surfaces that are compatible with TPU to improve adhesion.

- Benefit: This helps reduce the chances of warping or the first layer peeling up from the bed.

3. Level the Print Bed Properly

- Why It Helps: A level bed ensures even first-layer adhesion. If the bed is uneven, it can cause adhesion issues, especially with flexible filaments like TPU.

- How to Do It: Ensure the print bed is perfectly level before starting the print. You can do this manually or use the printer’s automatic bed leveling function, if available.

4. Slow Down the First Layer Print Speed

Why It Helps: Printing the first layer slower gives TPU more time to adhere properly to the glass bed. TPU is a flexible material, and printing too fast can result in poor adhesion or warping.

How to Do It: In your slicer settings, reduce the first-layer print speed to 50% of your normal print speed. This will help ensure the first layer has better adhesion and lays down smoothly.

5. Use a Brim or Raft

- Why It Helps: A brim or raft increases the surface area of the first few layers, which improves adhesion to the bed and helps prevent warping.

- How to Do It: In your slicer, enable a brim (usually 5-10 lines around the base of your print) or a raft (a thick base layer) to improve the adhesion and reduce the risk of warping.

- Benefit: This is especially helpful for larger prints or those with smaller contact areas on the print bed.

6. Ensure Good Bed Cleanliness

- Why It Helps: A clean print bed ensures better adhesion and prevents contamination that could cause print failures.

- How to Do It: Clean the glass bed with isopropyl alcohol or a mild detergent before every print to remove any oil, dust, or residue that could interfere with adhesion.

Benefit: A clean bed improves the overall quality of your prints and helps the TPU filament adhere better.

Summary:

Yes, TPU can be printed on a glass bed, but to achieve the best results, you should use a heated bed (50°C to 60°C), apply an adhesion aid (like a glue stick or hairspray), level the bed properly, and print at a slower speed for the first layer. You can also use a brim or raft to enhance bed adhesion and prevent warping. These steps will help ensure that your TPU prints successfully on a glass bed.