Mastering 3D Printing: Essential Tips for Optimizing Print Settings

3D Printing and the Critical Role of Print Settings

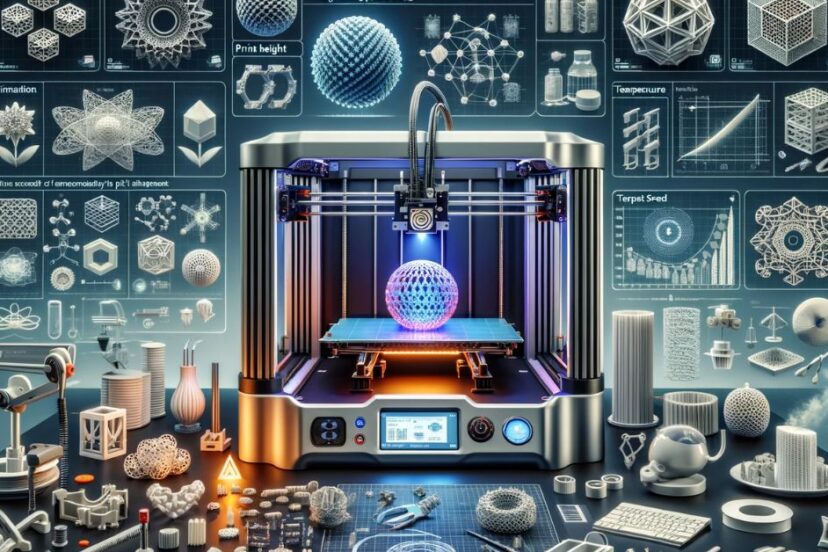

3D printing, a marvel of modern technology, has transformed how we create and manufacture objects. As an enthusiast and advisor in this exciting field, I’ve learned that one of the most crucial aspects of 3D printing is mastering print settings. The right settings can mean the difference between a flawless print and a failed project.

Understanding Layer Height, Infill Density, and Print Speed: The Triad of 3D Print Quality

Let’s delve deeper into the triad of 3D print quality: layer height, infill density, and print speed. These three factors play a crucial role in determining the success and quality of a 3D print.

- Layer Height: The Detail Resolution

- What Is Layer Height?

- Layer height, often measured in microns (1000 microns = 1mm), refers to the thickness of each individual layer of filament laid down during the 3D printing process.

- Impact on Print Quality

- A lower layer height, say 50-100 microns, leads to higher resolution prints with finer details, smoother surfaces, and less visible layer lines.

- Conversely, a higher layer height, like 200-300 microns, speeds up the printing process but results in rougher texture and more visible layers.

- Balancing Act

- Choosing the right layer height is a balance between the desired quality and the acceptable print time. High-resolution models require patience and time, suitable for intricate models like miniatures or jewelry. On the other hand, functional parts like prototypes or simple tools can tolerate higher layer heights for quicker results.

- Infill Density: The Internal Structure

- Defining Infill Density

- Infill density is the percentage of the interior volume of the print that is filled with material. It ranges from sparse (10-15%) to solid (100%).

- Strength vs. Material and Time Efficiency

- Higher infill density increases the strength and weight of the printed object but also uses more filament and extends print time.

- Lower infill density reduces material usage and speeds up the printing process but can compromise the object’s strength and structural integrity.

- Application-Specific Choices

- For decorative items or parts not subjected to stress, a lower infill is sufficient. For functional parts under load or stress, a higher infill ensures durability.

- Print Speed: The Efficiency Factor

- Speed’s Role in 3D Printing

- Print speed, typically measured in millimeters per second (mm/s), is how fast the printer head moves while laying down the filament.

- Quality vs. Time

- Slower print speeds generally yield higher quality prints with smoother finishes and finer details.

- Faster speeds can significantly reduce print times but may lead to issues like shaking, poor layer adhesion, or imperfections in detail.

- Finding the Sweet Spot

- The optimal print speed varies based on printer capabilities, filament type, and the complexity of the print. It often requires experimentation to find the right balance between time efficiency and print quality.

By understanding and adjusting these three parameters – layer height, infill density, and print speed – you can significantly influence the outcome of your 3D printing projects. Each parameter offers a trade-off between quality, strength, and efficiency, and finding the right balance is key to achieving successful prints. Experimentation and experience play a vital role in mastering these settings for various printing needs.

Optimizing Print Settings for Various Objects: A Tailored Approach

Optimizing print settings for various objects in 3D printing requires a tailored approach. The settings that work best for one type of object might not be ideal for another. This customization hinges on understanding the unique requirements of each print project, from detailed figurines to functional mechanical parts.

- Settings for Detailed vs. Functional Prints

- Detailed Prints

- Layer Height: For highly detailed prints like miniatures or intricate models, a lower layer height (around 50-100 microns) is preferable. This ensures finer detail and smoother surfaces.

- Infill Density: While detailed prints require high external detail, they don’t necessarily need to be strong internally. A moderate to low infill density is often sufficient.

- Print Speed: A slower print speed is critical for detailed prints to allow greater precision in laying down each layer.

- Functional Prints

- Layer Height: Functional parts, like mechanical components or tools, can tolerate higher layer heights (200-300 microns) as surface detail is less critical, and the focus is on strength and print time.

- Infill Density: A higher infill density is vital for functional prints to ensure they can withstand the stress or load they will be subjected to.

- Print Speed: Functional prints can be produced at a faster speed since the emphasis is more on strength and less on fine detail.

- Adjusting for Size and Shape Variations

- Small and Complex Objects

- Small objects with complex geometries require careful calibration of print settings. For instance, cooling settings become crucial here to prevent warping or deformation.

- Large Objects

- Large prints may require different settings to maintain structural integrity and minimize printing time. For instance, a slightly higher layer height and infill pattern adjustments can be effective.

- Material Considerations

- Different materials behave differently under the same print settings. For example, flexible filaments like TPU might require slower print speeds and special attention to extrusion settings compared to rigid materials like PLA.

- Overhangs and Supports

- Prints with significant overhangs or unsupported structures require careful settings adjustments, particularly in the support generation. The density, type, and positioning of supports are critical to the print’s success.

- Environmental Factors

- The printing environment, such as ambient temperature and humidity, can also affect print quality. For instance, temperature-sensitive materials might require an enclosed printing chamber.

- Printer Specifics

- Each 3D printer has its quirks and capabilities. Understanding your machine’s strengths and limitations is crucial for optimizing settings for different objects.

- Experimentation and Documentation

- Since there’s no one-size-fits-all approach, it’s essential to experiment with different settings to see what works best for each type of print. Documenting these settings for future reference can save time and improve consistency.

Optimizing print settings for different types of objects in 3D printing is both an art and a science. It requires a deep understanding of the interplay between print settings and the specific requirements of each print. By tailoring these settings to the unique needs of each project, you can achieve the best possible results, whether you’re printing delicate models or robust mechanical parts. Experimentation, patience, and a willingness to learn from each print are key to mastering this optimization process.

Fine-Tuning Temperature for Different Filaments: The Heat is On

Fine-tuning the temperature settings for different filament types in 3D printing is a critical aspect of achieving optimal print quality. Each filament material has unique thermal properties that dictate how it behaves when heated and extruded. Understanding and adjusting the extruder and bed temperatures for these materials is essential for successful printing.

- Temperature Considerations for Common Filaments

- PLA (Polylactic Acid)

- Extruder Temperature: Typically between 180°C and 220°C. PLA is forgiving and works well at lower temperatures, making it ideal for beginners.

- Bed Temperature: Usually between 20°C to 60°C. A heated bed is not always necessary for PLA, but a moderate temperature can help with bed adhesion.

- ABS (Acrylonitrile Butadiene Styrene)

- Extruder Temperature: Higher than PLA, usually between 220°C and 250°C. ABS requires a higher temperature to properly melt and extrude.

- Bed Temperature: Essential to be heated, around 80°C to 110°C. A heated bed prevents warping and helps with layer adhesion.

- PETG (Polyethylene Terephthalate Glycol)

- Extruder Temperature: Ranges from 230°C to 250°C. PETG combines the ease of printing of PLA with the strength and temperature resistance of ABS.

- Bed Temperature: Typically between 70°C and 90°C. A heated bed helps in reducing warping and sticking issues.

- How Temperature Affects Print Quality

- Under-Extrusion and Over-Extrusion

- If the temperature is too low, the filament may not extrude properly, leading to under-extrusion. Conversely, too high a temperature can cause over-extrusion, stringing, and oozing.

- Warping and Cracking

- ABS, in particular, is prone to warping and cracking if the temperature is not correctly maintained. A stable, heated environment is crucial for printing with ABS.

- Surface Quality

- The temperature can affect the glossiness and smoothness of the print. For instance, higher temperatures with PLA can result in a shinier surface but might also lead to stringing.

- Adjusting for Filament Variations

- Not all filaments of the same type are created equal. Variations in composition and color additives can require slight adjustments in temperature settings.

- The Role of the Print Bed

- A heated bed is essential for materials like ABS and PETG, not just for adhesion but also to ensure a gradual cooling of the print to prevent warping.

- Monitoring and Adjusting During Print

- It’s often beneficial to monitor the first few layers of a print and adjust the temperature if you notice issues like poor adhesion, stringing, or poor layer quality.

- Environmental Considerations

- Ambient temperature and drafts can affect print temperature. Enclosed printers can mitigate these environmental factors, especially for temperature-sensitive materials.

- Experimentation and Fine-Tuning

- Each printer and filament batch can behave slightly differently. It’s important to experiment with small test prints to fine-tune the temperature settings for your specific setup.

Fine-tuning the temperature for different filaments in 3D printing is a nuanced and vital part of the printing process. Correct temperature settings lead to better print quality, fewer failures, and more consistent results. While manufacturer recommendations provide a good starting point, the best settings are often found through personal experimentation and adjustment to your specific printer and environment.

The Art of Support Structures in Complex Prints

The use of support structures in 3D printing is a critical aspect, especially for complex prints with overhangs, bridges, and intricate geometries. These supports act as temporary scaffolds, ensuring that every part of the object is printed accurately and with the necessary support, regardless of its shape or complexity.

- Types of Support Structures

- Touching Buildplate Supports

- These supports extend from the build plate up to the part of the object that needs support.

- Ideal for objects with overhangs that start above the build plate.

- Everywhere Supports

- These supports are used when parts of the print hang over other parts of the print, necessitating supports that start from the model itself.

- Essential for very complex geometries with multiple overhangs.

- Tree Supports

- Resemble branches of a tree. These are efficient in material use and often easier to remove.

- Useful for intricate designs where traditional supports might be too invasive or hard to remove.

Dissolvable Supports

- Made from a different material that can be dissolved away after printing.

- Ideal for extremely complex prints where removing physical supports would be difficult or impossible without damaging the print.

2. Customizing Supports for Overhangs and Bridges

- Overhang Angle

- Adjusting the angle at which supports are generated. Steeper angles might not require supports, while shallower angles do.

- Support Density

- The density of the support structure affects how easy it is to remove and how much it supports the print.

- A denser support provides more stability but is harder to remove and uses more material.

- Support Pattern

- Different patterns (grid, lines, zigzag, etc.) offer varying balances between strength and ease of removal.

- Considerations for Successful Support Printing

- Material Usage

- More supports mean more material used, increasing the cost and print time.

- Surface Finish

- The part of the model where the support connects can have a rougher finish and may require post-processing.

- Ease of Removal

- Supports should be designed for easy removal without damaging the print. Settings like ‘Z distance’ or ‘horizontal offset’ can be tweaked for this purpose.

- Software and Slicer Settings

- Most slicer software provides advanced settings to customize supports based on the model’s needs.

- Experimentation and Learning

- The right balance for support structures often comes down to experimentation and experience. What works for one print might not work for another.

- Trial and error, along with learning from each print, are essential in mastering the use of supports.

- Post-Processing

- After the print is complete, supports are removed. This process can be as simple as snapping them off or as involved as dissolving them in a solvent bath.

- Some light sanding or other finishing techniques may be necessary where the supports connected to the print.

The art of using support structures in 3D printing lies in understanding when and how to use them effectively. By tailoring the type, density, and pattern of supports to the specific needs of each print, you can ensure success even with the most complex designs. Balancing material use, ease of removal, and final print quality is key, making the use of supports a skill that improves with practice and experience.

Bridging the Gap: Mastering Advanced Settings

In 3D printing refers to the fine-tuning of printer settings to effectively handle complex features like bridges and overhangs. These features are challenging because they involve printing over open air or at angles unsupported by the layer below. Mastering these settings is essential for achieving high-quality prints without the need for excessive support structures.

- Understanding Bridging and Overhangs

- Bridging: This occurs when filament is extruded between two points with empty space underneath. The challenge is to prevent the filament from sagging.

- Overhangs: These are parts of the print that extend beyond the layer below but are not as extreme as bridges. Overhangs require careful cooling and speed adjustments to maintain shape.

- Techniques for Successful Bridging

- Bridging Speed and Flow Rate

- Reducing the speed during bridging allows the filament to cool and solidify more quickly, reducing sag.

- Adjusting the flow rate (amount of extruded filament) can prevent excess material from weighing down the bridge.

- Cooling

- Increased cooling is crucial for bridging. A strong fan setting helps to rapidly cool the filament as it’s laid down, preventing sagging.

- Layer Height and Width

- Lower layer heights can improve bridging as they require less filament and are more easily cooled.

- Wider extrusion widths can offer more stability to the bridge.

- Overcoming Overhang Challenges

- Supports for Overhangs

- While not always necessary, supports can be useful for extreme overhangs.

- The goal is to use minimal supports to achieve the desired quality, reducing material use and post-processing time.

- Print Angle and Orientation

- Sometimes, simply changing the orientation of the print on the build plate can reduce the severity of overhangs, minimizing the need for supports.

- Temperature Adjustments

- Lower extrusion temperatures can help with overhangs by reducing drooping, but this needs to be balanced against proper filament adhesion and strength.

- Utilizing Slicer Software for Optimization

- Most slicer software provides specific settings for bridges and overhangs, allowing for fine-tuning of speed, flow rate, cooling, and more.

- Using preview modes in slicer software can help identify potential problem areas before printing begins.

- Experimentation: The Key to Mastery

- Each printer and filament can behave differently, so finding the optimal settings often requires experimentation.

- Test prints designed specifically for bridging and overhang challenges can be very useful for dialing in these settings.

- Community Insights and Shared Profiles

- Leverage the knowledge of the 3D printing community. Many users share their settings and profiles for specific printers and materials, which can be a great starting point.

Mastering bridging and overhangs in 3D printing is about understanding the capabilities and limitations of both the printer and the filament. By fine-tuning settings like speed, cooling, and extrusion rates, and using slicer software intelligently, you can bridge the gap effectively, producing clean, structurally sound prints. As with many aspects of 3D printing, achieving proficiency in handling these advanced settings comes down to a mix of knowledge, experimentation, and learning from the community.

Documenting Your Journey: The Importance of Print Profiles

In the context of 3D printing speaks to the value of meticulously recording and organizing the settings and parameters used for different print jobs. This practice is essential for several reasons, primarily for ensuring consistency in print quality and for efficiently managing various printing projects.

- What are Print Profiles?

- Definition

- Print profiles are comprehensive records of all the settings used for a particular 3D print. This includes layer height, infill density, print speed, temperature settings, cooling, and any other relevant parameters.

- Purpose

- They serve as a blueprint for reproducing the same quality and characteristics of a print, which is especially useful when reprinting or adjusting projects.

- Benefits of Maintaining Print Profiles

- Consistency in Printing

- By using established profiles, you can achieve consistent results, especially important for producing multiple parts of the same project or for commercial purposes where uniformity is key.

- Time Efficiency

- Once a successful print profile is developed, it can save considerable time on future projects. There’s no need to recalibrate or go through trial and error for every new print.

- Troubleshooting and Improvements

- Documenting profiles allows for easier troubleshooting of printing issues. By comparing profiles, you can identify what changes might have led to different outcomes.

- Creating a Print Settings Library

- Organizing Profiles

- Organize profiles by material type, print type (detailed, functional, large, small), and even by printer if you use multiple machines.

- Software Use

- Many slicing software packages allow you to save and categorize these profiles directly within the software, making them easily accessible for future prints.

- Sharing and Collaborating

- Community Sharing

- The 3D printing community often shares profiles for specific printers and materials. Using these shared profiles as a starting point can be a huge time-saver.

- Collaboration

- In professional or educational settings, sharing profiles ensures that team members are on the same page and can replicate results.

- Documentation as a Learning Tool

- Reflecting on Past Prints

- Keeping a record of your print profiles, including both successes and failures, is a valuable learning tool. It allows you to reflect on your journey and understand how different settings impact the final print.

- Iterative Improvement

- Documenting allows for an iterative approach to improving print quality. You can make small, incremental changes to a profile and directly see the results.

- Best Practices for Documenting Profiles

- Detailed Notes

- Include notes on specific challenges or adjustments made during the print process.

- Version Control

- Keep versions of profiles, especially if you make significant changes, so you can revert to a previous version if needed.

In 3D printing, documenting and managing print profiles is a critical aspect of mastering the craft. It not only fosters consistency and efficiency but also serves as a valuable tool for learning and collaboration. Whether you are a hobbyist, a professional, or part of a collaborative team, maintaining a detailed library of print profiles will significantly enhance your 3D printing experience.

Avoiding Pitfalls: Common Mistakes in 3D Printing

Navigating the intricate world of 3D printing involves not just mastering the techniques but also being aware of and avoiding common pitfalls. These mistakes can range from simple oversights to more complex technical misunderstandings. By recognizing and learning how to circumvent these issues, you can greatly enhance the success rate and quality of your 3D prints.

- Incorrect Bed Leveling

- The Issue: One of the most common mistakes is improper bed leveling. An uneven bed leads to adhesion problems, affecting the first layer’s quality, which is crucial for the print’s overall success.

- The Solution: Regularly check and adjust the bed leveling. Using a feeler gauge or a piece of paper to measure the distance between the nozzle and the bed can ensure consistent leveling.

- Inadequate Temperature Control

- The Issue: Incorrect extruder or bed temperature settings can lead to various problems, like warping, poor layer adhesion, or stringing.

- The Solution: Use the recommended temperature settings for your filament and adjust based on your printer’s performance and environmental conditions.

- Wrong Print Speed Settings

- The Issue: Setting the print speed too high can lead to shaky prints, poor adhesion, and lack of detail. Conversely, too slow a speed can result in unnecessarily long print times.

- The Solution: Find a balanced speed that works for your printer and project. Consider different speeds for different parts of the print (e.g., slower for detailed areas).

- Neglecting Filament Quality and Storage

- The Issue: Using low-quality filament or poorly stored filament can cause issues like clogging, uneven extrusion, and weak prints.

- The Solution: Invest in good quality filament and store it properly, away from moisture and dust. Using a filament dry box is advisable, especially for materials like nylon.

- Overlooking Slicer Software Settings

- The Issue: The slicer software, which converts your 3D model into printer instructions, has numerous settings that can be overwhelming. Incorrect settings can lead to various print issues.

- The Solution: Take the time to understand and correctly configure your slicer settings. Utilize community resources or profiles as a starting point.

- Ignoring Machine Maintenance

- The Issue: Regular wear and tear can affect print quality. Neglecting maintenance like tightening loose belts or lubricating moving parts can lead to problems.

- The Solution: Develop a regular maintenance routine for your printer. Check for loose screws, ensure belts are tight, and lubricate moving parts as needed.

- Improper First Layer Settings

- The Issue: The first layer is fundamental to print success. Too close or too far from the bed, and the rest of the print can fail.

- The Solution: Pay special attention to first layer settings in your slicer software. Adjust the nozzle height and first layer speed and width for optimal adhesion.

- Lack of Post-Processing Consideration

- The Issue: Not planning for post-processing can lead to prints that are difficult to clean up or finish.

- The Solution: Design with post-processing in mind. Include features that make support removal easier, and plan for sanding, painting, or other finishing processes.

Avoiding these common pitfalls in 3D printing requires a mix of careful planning, regular maintenance, and a willingness to learn and adapt. Each mistake offers a learning opportunity and a chance to refine your approach. By staying mindful of these issues and proactively addressing them, you can significantly improve your 3D printing experience and the quality of your prints.

Community Wisdom: Leveraging Collective Knowledge

In the context of 3D printing highlights the immense value of tapping into the shared experiences, insights, and solutions from the broader 3D printing community. This community, comprising hobbyists, professionals, and enthusiasts, is a rich source of knowledge that can significantly enhance individual 3D printing practices.

- Learning from Shared Experiences

- Wide Range of Knowledge: The 3D printing community is diverse, with members ranging from beginners to highly experienced professionals. This variety ensures a wide range of perspectives and solutions.

- Problem Solving: Common printing issues have often been encountered and solved by others. Accessing community forums or groups can provide quick solutions to problems that new printers might face.

- Online Forums and Communities

- Popular Platforms: Websites like Reddit, Thingiverse, and specialized forums like Ultimaker’s community forum, are treasure troves of information where users share advice, designs, and problem-solving strategies.

- Active Engagement: Participating in these forums not only helps in solving your own queries but also contributes to the collective knowledge pool.

- Utilizing Shared Print Profiles

- Profiles for Different Printers and Materials: Experienced users often share their printer profiles for specific materials and models. These can serve as excellent starting points for newcomers or those trying new materials.

- Calibration and Refinement: These profiles can also help in understanding the calibration and refinement process, guiding through the nuances of fine-tuning printer settings.

- Collaborative Projects and Open Source Contributions

- Community Projects: Many community-led projects allow for collaborative work, contributing to larger initiatives or open-source projects.

- Open Source Software and Hardware: The 3D printing community strongly supports open-source principles, leading to a wealth of freely available resources, including software, hardware designs, and printing models.

- Workshops, Meetups, and Conferences

- Local and Online Meetups: Attending workshops and meetups, either virtually or in-person, is a great way to connect with other 3D printing enthusiasts and professionals.

- Conferences and Trade Shows: Larger events like trade shows or conferences offer opportunities to learn about the latest trends, technologies, and materials in 3D printing.

- Video Tutorials and Online Courses

- Learning Through Visual Guides: Video platforms like YouTube have countless tutorials ranging from basic to advanced techniques.

- Structured Learning: Online courses on platforms like Udemy or Coursera offer a more structured approach to learning 3D printing, often guided by experts in the field.

- Social Media Groups and Hashtags

- Real-Time Interaction: Social media platforms like Facebook, Instagram, and Twitter have active 3D printing communities. Following specific hashtags can lead to a wealth of shared knowledge and inspiration.

- The Importance of Giving Back

- Sharing Your Journey: As you grow in your 3D printing journey, sharing your experiences, successes, and failures can help others.

- Mentorship and Support: Providing support and mentorship to newer members not only enriches the community but also strengthens your understanding and mastery of 3D printing.

In the ever-evolving world of 3D printing, leveraging community wisdom is invaluable. This collective knowledge accelerates learning, inspires innovation, and fosters a supportive environment for both newcomers and veterans in the field. Engaging with and contributing to this community can significantly enhance your skills, understanding, and enjoyment of 3D printing.

Conclusion:

The Never-Ending Journey of Improvement

Mastering print settings in 3D printing is an ongoing journey. Each print is an opportunity to learn and improve. So, keep experimenting, keep documenting, and most importantly, keep printing!

FAQs

- What’s the best layer height for detailed prints?

The ideal layer height for detailed prints is typically around 0.1mm, providing a good balance between detail and print time. - How does infill density affect print strength?

Higher infill density increases the strength of the print but uses more material and increases print time. - Can I use the same temperature settings for all filaments?

No, different filaments require different temperature settings. PLA usually prints at lower temperatures compared to ABS. - What are the best practices for printing overhangs?

For overhangs, using proper support structures, cooling, and adjusting print speed are key. - How important is it to document print settings?

It’s very important as it saves time for future prints and provides a basis for further experimentation.