Speed vs. Quality: Finding the Right Balance in 3D Printing

As an avid enthusiast and advisor in the realm of 3D printing, I understand the age-old dilemma that plagues every maker and creator: the eternal tug-of-war between speed and quality. In this article, we’re going to dive headfirst into the world of 3D printing and explore how to strike that perfect equilibrium between rapid production and impeccable precision.

The Need for Speed

The Fastest 3D Printers on the Market

When speed is of the essence in 3D printing, having the right printer can make all the difference. Here, we explore some of the fastest 3D printers available today, pushing the boundaries of rapid prototyping and production.

Ankor Make M5C

The Ankor Make M5C has made waves in the 3D printing industry with its lightning-fast printing speeds. Using innovative technologies and cutting-edge engineering, it boasts impressive print speeds without compromising on quality. Equipped with advanced features such as high-flow extruders and optimized print pathways, the Ankor Make M5C can churn out prints at remarkable speeds, making it an ideal choice for time-sensitive projects and high-volume production.

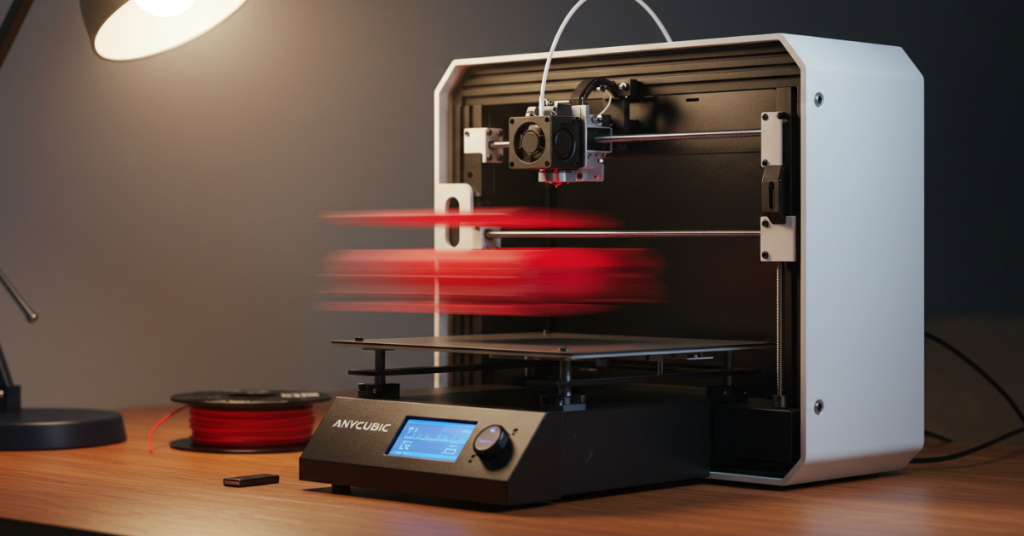

Anycubic Kobra 2

The Anycubic Kobra 2 is another contender in the realm of high-speed 3D printing. With a focus on efficiency and performance, it leverages state-of-the-art components and intelligent design to achieve unparalleled printing speeds. Whether you’re prototyping new designs or producing functional parts on demand, the Anycubic Kobra 2 delivers consistent results with minimal downtime. Its user-friendly interface and robust construction make it a favorite among professionals seeking maximum throughput without sacrificing quality.

Prusa MK4

The Prusa MK4 rounds out our selection of the fastest 3D printers on the market. Renowned for its blistering print speeds and versatility, the Prusa MK4 excels in a wide range of applications, from rapid prototyping to small-batch manufacturing. Featuring a sleek design and intuitive software interface, it streamlines the printing process, allowing you to bring your ideas to life with unparalleled speed and precision. Whether you’re a hobbyist, a designer, or an industrial engineer, the Prusa MK4 offers the speed and reliability you need to stay ahead of the curve.

These printers represent the pinnacle of speed and efficiency in the world of 3D printing. By harnessing the latest technologies and innovations, they empower makers and manufacturers to push the boundaries of what’s possible, delivering quality prints in record time. When speed is paramount, investing in one of these top-tier printers ensures that you can meet tight deadlines and accelerate your creative endeavors with confidence.

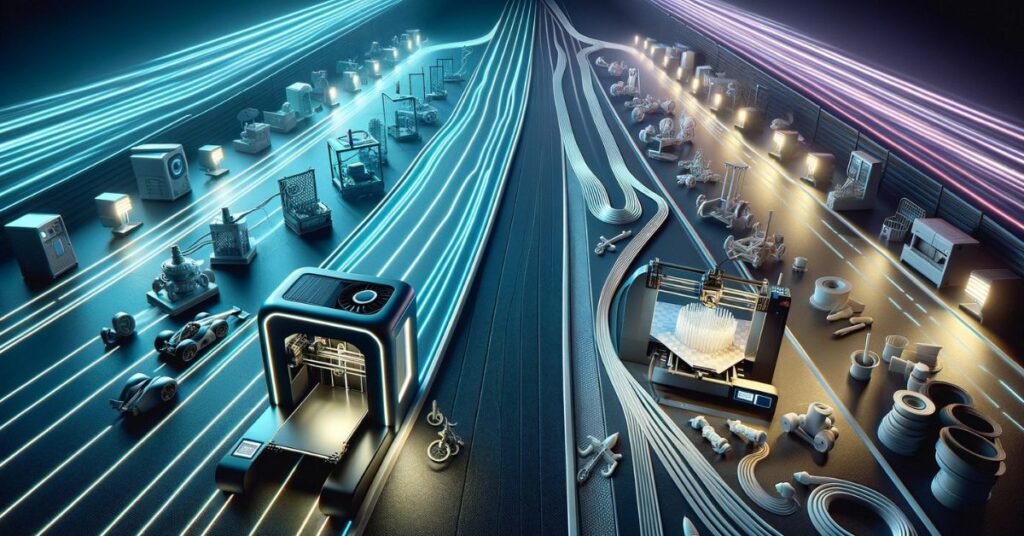

Speed in Prototyping

Prototyping is a fundamental stage in the product development process, where ideas are transformed into tangible models for testing and validation. In today’s fast-paced world, the ability to iterate quickly is essential for staying competitive. Here, we delve into how speed plays a crucial role in prototyping through 3D printing.

Rapid Iteration

Speed is synonymous with agility in prototyping. The faster you can iterate on designs, the quicker you can identify flaws, refine concepts, and ultimately, bring a polished product to market. 3D printing revolutionizes prototyping by significantly reducing the time required to create physical models. With traditional manufacturing methods, prototyping can take weeks or even months. However, with 3D printing, iterations can be completed in a matter of hours or days, accelerating the entire product development cycle.

On-Demand Prototyping

3D printing enables on-demand prototyping, allowing designers and engineers to create prototypes as needed, without relying on external suppliers or tooling facilities. This flexibility eliminates the lead times associated with traditional prototyping methods, empowering teams to respond quickly to design changes, customer feedback, and market demands. Whether it’s a concept sketch in the morning or a fully realized prototype by the end of the day, 3D printing puts rapid prototyping within reach like never before.

Design Validation

Speed in prototyping facilitates rapid design validation, enabling designers to test multiple iterations of a product in real-world conditions. By quickly producing physical prototypes, designers can assess factors such as form, fit, function, and ergonomics, ensuring that the final product meets user needs and design specifications. This iterative process of testing and refinement is essential for identifying and addressing potential issues early in the development cycle, ultimately saving time and resources down the line.

Time-to-Market Advantage

In today’s competitive landscape, time-to-market is critical for success. Speed in prototyping gives companies a significant advantage by accelerating product development timelines and enabling faster commercialization. By leveraging 3D printing for rapid prototyping, businesses can iterate quickly, validate designs efficiently, and bring innovative products to market ahead of the competition. This agility allows companies to capitalize on emerging trends, respond to customer needs, and stay at the forefront of their industries.

Speed in prototyping is essential for driving innovation, accelerating product development, and gaining a competitive edge in the market. 3D printing empowers designers and engineers to iterate quickly, validate designs effectively, and bring ideas to life faster than ever before. By embracing speed in prototyping, companies can streamline their product development processes, reduce time-to-market, and ultimately, achieve greater success in today’s dynamic business environment.

Production Efficiency

Efficiency in production is paramount for businesses aiming to streamline operations, reduce costs, and meet customer demand in a timely manner. In this section, we’ll discuss how speed in 3D printing enhances production efficiency across various industries.

Rapid Manufacturing

Speed is a game-changer in manufacturing, where every minute counts. 3D printing enables rapid manufacturing by significantly reducing lead times compared to traditional manufacturing methods. With 3D printing, complex parts can be produced in a fraction of the time it takes with conventional machining or molding processes. This agility allows manufacturers to respond quickly to changing market demands, produce custom or low-volume parts on demand, and optimize production schedules for maximum efficiency.

Just-in-Time Manufacturing

Just-in-Time (JIT) manufacturing is a strategy aimed at minimizing inventory and waste by producing goods only as they are needed. 3D printing aligns perfectly with JIT principles, as it enables on-demand production of parts and components without the need for costly tooling or setup. By leveraging 3D printing for JIT manufacturing, companies can reduce warehousing costs, eliminate excess inventory, and improve cash flow. This lean approach to production ensures that resources are allocated efficiently, leading to increased profitability and competitiveness.

Agile Supply Chains

In today’s globalized economy, supply chains must be agile and responsive to changing market conditions. 3D printing enhances supply chain agility by decentralizing production and reducing reliance on centralized manufacturing facilities. With 3D printing, companies can establish distributed manufacturing networks, enabling localized production closer to end markets. This reduces shipping costs, shortens lead times, and minimizes supply chain disruptions caused by factors such as natural disasters or geopolitical events. By leveraging 3D printing for agile manufacturing, companies can adapt quickly to market changes, mitigate risks, and maintain a competitive edge in an increasingly volatile business environment.

Customization and Personalization

Consumers increasingly expect personalized products tailored to their unique preferences and needs. 3D printing enables mass customization by allowing manufacturers to produce bespoke products at scale. Whether it’s customized consumer goods, personalized medical devices, or tailor-made automotive parts, 3D printing empowers companies to meet individual customer requirements without sacrificing production efficiency. This flexibility not only enhances customer satisfaction but also opens up new revenue streams and market opportunities for businesses willing to embrace customization as a competitive advantage.

Production efficiency is critical for driving competitiveness and profitability in today’s fast-paced business landscape. By harnessing the speed and flexibility of 3D printing, companies can optimize production processes, reduce costs, and meet customer demand with greater agility and precision. Whether it’s rapid manufacturing, just-in-time production, agile supply chains, or mass customization, 3D printing offers endless possibilities for enhancing efficiency and innovation across industries.

Saving Time and Costs

Time and cost savings are central concerns for businesses across industries. In this section, we’ll explore how speed in 3D printing translates into significant time and cost savings, driving efficiency and competitiveness.

Reduced Lead Times

One of the most significant benefits of 3D printing is its ability to dramatically reduce lead times compared to traditional manufacturing methods. With 3D printing, complex parts can be designed, prototyped, and produced in a fraction of the time it takes with conventional processes. This accelerated timeline enables companies to bring products to market faster, seize opportunities, and respond swiftly to changing customer demands.

Elimination of Tooling Costs

Unlike traditional manufacturing methods that require expensive tooling and molds, 3D printing eliminates the need for such capital-intensive investments. With 3D printing, parts are built layer by layer directly from digital designs, bypassing the need for costly tooling setups. This cost-saving advantage is particularly beneficial for small-batch production, custom manufacturing, and rapid prototyping, where tooling costs can be prohibitive.

On-Demand Production

3D printing enables on-demand production, allowing companies to manufacture parts and components as needed, without the need for large inventories or warehousing facilities. By producing goods on-demand, companies can minimize inventory carrying costs, reduce the risk of overstocking or obsolescence, and optimize cash flow. This lean approach to production ensures that resources are allocated efficiently, leading to cost savings and improved profitability.

Design Iteration Savings

In traditional manufacturing, each design iteration requires the production of new molds, tooling, or prototypes, leading to significant time and costs. With 3D printing, design iterations can be made quickly and affordably, as digital designs can be modified and printed on-demand with minimal setup time. This iterative approach to design saves both time and costs associated with physical prototyping, enabling companies to refine their products more efficiently and cost-effectively.

Material Efficiency

3D printing minimizes material waste by only using the exact amount of material required to build each part. Unlike subtractive manufacturing methods that generate significant waste through machining or milling, 3D printing adds material layer by layer, optimizing material usage and reducing costs. This material efficiency not only saves money but also aligns with sustainable manufacturing practices, reducing environmental impact.

3D printing offers significant time and cost savings across various stages of the product lifecycle. From reduced lead times and elimination of tooling costs to on-demand production and material efficiency, the speed and flexibility of 3D printing drive efficiency, innovation, and competitiveness in today’s dynamic business environment. By leveraging 3D printing technologies, companies can achieve greater agility, profitability, and success in their respective industries.

The Pursuit of Perfection

Precision Matters

In 3D printing, precision is paramount. The ability to produce accurate, high-quality parts with intricate details directly impacts the functionality, performance, and aesthetic appeal of the final product. Here, we delve into why precision matters in 3D printing and how it contributes to overall success.

Functional Prototyping

Precision is crucial when creating functional prototypes that closely mimic the intended design and functionality of the final product. Whether it’s testing the fit of mechanical components, assessing the performance of intricate features, or evaluating the assembly of complex mechanisms, precise 3D prints enable engineers and designers to identify potential issues early in the development process. This ensures that the final product meets performance requirements and functions as intended, reducing the risk of costly redesigns or production errors down the line.

Complex Geometries

3D printing excels at producing parts with complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. From intricate lattice structures and organic shapes to interlocking components and internal channels, precision is essential for ensuring the dimensional accuracy and integrity of these complex designs. Precise 3D printing allows for the faithful reproduction of intricate details, ensuring that each layer is deposited with precision to maintain the integrity of the overall geometry.

Medical Applications

In the field of medicine, precision is critical for producing patient-specific implants, prosthetics, and surgical guides tailored to individual anatomies. Precise 3D printing enables medical professionals to create custom solutions that fit precisely and perform optimally, reducing the risk of complications and improving patient outcomes. Whether it’s a dental crown designed to fit seamlessly in a patient’s mouth or a titanium implant precisely shaped to match a bone defect, precision in 3D printing is essential for delivering personalized healthcare solutions.

Aerospace and Automotive Industries

In aerospace and automotive industries, where safety and performance are paramount, precision in manufacturing is non-negotiable. 3D printing allows for the production of lightweight, high-strength components with intricate geometries and tight tolerances. These precision-engineered parts contribute to fuel efficiency, aerodynamic performance, and overall vehicle performance. From turbine blades and engine components to lightweight structures and aerodynamic surfaces, precise 3D printing plays a crucial role in advancing innovation and pushing the boundaries of what’s possible in these industries.

Quality Assurance

Finally, precision is essential for ensuring quality throughout the 3D printing process. From the initial design phase to post-processing and finishing, maintaining precise control over parameters such as layer height, print speed, and material properties is key to achieving consistent, high-quality results. Quality assurance measures, such as calibration, material testing, and post-print inspections, help identify and address any deviations from desired specifications, ensuring that each print meets the required standards of precision and accuracy.

Precision is a cornerstone of successful 3D printing across industries. Whether it’s functional prototyping, complex geometries, medical applications, or aerospace and automotive manufacturing, precise 3D printing enables innovation, customization, and quality assurance at every stage of the product lifecycle. By prioritizing precision in 3D printing, companies can achieve superior results, drive innovation, and deliver products that meet the highest standards of performance and reliability.

Print Resolution Explained

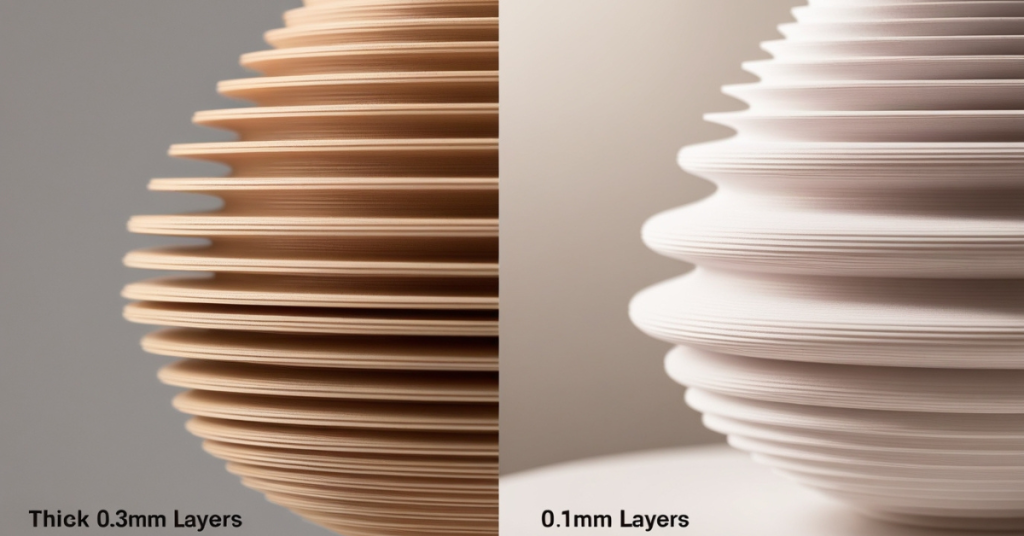

Print resolution is a critical factor in 3D printing that directly impacts the quality and detail of printed objects. Understanding print resolution and its implications is essential for achieving the desired level of precision and aesthetics in 3D printed parts. Here, we’ll delve into what print resolution is, how it’s measured, and its significance in the 3D printing process.

Definition of Print Resolution

Print resolution refers to the level of detail or fineness that can be achieved in a 3D printed object. It is determined by the smallest increment in the X, Y, and Z axes that the 3D printer can accurately reproduce. In other words, print resolution describes the smallest features or details that can be represented in a printed part.

Measuring Print Resolution

Print resolution is typically measured in terms of layer height, which refers to the thickness of each layer deposited by the 3D printer during the printing process. The smaller the layer height, the finer the resolution and the smoother the surface finish of the printed object. Printers with higher resolution capabilities can produce finer details and more intricate geometries, resulting in higher-quality prints.

Impact on Print Quality

Print resolution directly influences the visual appearance, dimensional accuracy, and structural integrity of 3D printed parts. Higher print resolution results in smoother surfaces, sharper edges, and finer details, leading to superior aesthetics and functionality. However, increasing print resolution typically requires longer print times and may require more advanced or specialized equipment.

Balancing Resolution and Speed

Achieving the optimal balance between print resolution and printing speed is essential in 3D printing. While higher resolution settings produce finer details and higher-quality prints, they also increase print times and material usage. Conversely, lower resolution settings can reduce print times but may sacrifice surface finish and detail. Balancing these factors is crucial to achieving the desired level of quality and efficiency in 3D printing projects.

Applications of Different Resolutions

Different applications may require varying levels of print resolution depending on factors such as the intended use of the printed part, aesthetic preferences, and functional requirements. For example:

- High Resolution: Applications requiring fine details and intricate geometries, such as jewelry, figurines, and prototypes with complex features.

- Medium Resolution: General-purpose applications where a balance between detail and speed is desired, such as architectural models, functional prototypes, and consumer products.

- Low Resolution: Rapid prototyping or conceptual modeling where speed is prioritized over surface finish and detail, such as initial design iterations or proof-of-concept prints.

Considerations for Print Resolution

When determining the appropriate print resolution for a project, consider factors such as the intended use of the printed part, the level of detail required, printing time constraints, and material limitations. Experimentation and testing with different resolution settings can help identify the optimal balance between print quality and efficiency for each specific application.

Print resolution is a fundamental aspect of 3D printing that significantly influences the quality, detail, and functionality of printed objects. By understanding the concept of print resolution and its implications, designers, engineers, and makers can make informed decisions to achieve the desired level of precision and aesthetics in their 3D printed creations.

Materials and Quality

The choice of material in 3D printing plays a critical role in determining the quality, strength, and functionality of printed objects. From thermoplastics and resins to metals and composites, each material offers unique properties that impact the final outcome. Here, we’ll delve into how material selection influences print quality and how to choose the right material for your 3D printing needs.

Material Properties

Different materials exhibit varying characteristics that affect print quality:

- Thermoplastics: Common thermoplastics such as PLA and ABS are popular choices for Fused Deposition Modeling (FDM) 3D printing. PLA is known for its ease of use and biodegradability, while ABS offers higher strength and heat resistance. Material properties such as layer adhesion, warping tendency, and print temperature impact the quality of prints produced with thermoplastics.

- Resins: Resin-based 3D printing technologies, such as Stereolithography (SLA) and Digital Light Processing (DLP), use liquid photopolymers that cure under UV light. Resins offer high resolution and smooth surface finishes, making them ideal for detailed models and prototypes. Material properties such as viscosity, curing time, and post-curing requirements influence the quality and characteristics of resin prints.

- Metals and Composites: Metal 3D printing processes, such as Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS), use metal powders to produce high-strength, complex parts. Metal prints offer exceptional mechanical properties and are suitable for applications requiring durability and precision. Composites, which combine materials such as carbon fiber or fiberglass with thermoplastics, offer enhanced strength and stiffness compared to pure polymers.

Print Quality Considerations

When selecting a material for 3D printing, consider the following factors that impact print quality:

- Surface Finish: Some materials produce smoother surface finishes than others. Resin-based 3D printing typically offers the highest level of detail and surface smoothness, while FDM prints may exhibit layer lines and texture.

- Strength and Durability: The mechanical properties of the material determine the strength and durability of printed parts. Metals and high-performance polymers offer superior mechanical properties compared to standard thermoplastics.

- Dimensional Accuracy: Material shrinkage, warping, and distortion during printing can affect dimensional accuracy. Choosing materials with low shrinkage and minimal warping tendencies can help maintain dimensional stability and accuracy.

- Printability: Consider the compatibility of the material with your 3D printer and its printing parameters. Some materials may require specific temperature settings, build plate adhesion methods, or post-processing techniques to achieve optimal print quality.

Matching Material to Application

Selecting the right material for your 3D printing application is essential for achieving the desired results:

- Functional Prototypes: For functional prototypes requiring mechanical testing, consider materials with properties that closely match the final production material, such as engineering-grade thermoplastics or metal alloys.

- Visual Prototypes: For prototypes intended for visual evaluation or presentation purposes, prioritize materials that offer high resolution and smooth surface finishes, such as resins or high-detail thermoplastics.

- End-Use Parts: When producing end-use parts, choose materials that offer the necessary strength, durability, and performance characteristics required for the application. Consider factors such as environmental conditions, load-bearing requirements, and regulatory compliance.

Testing and Iteration

Experimentation and testing with different materials can help identify the optimal material for your specific application. Conducting test prints, evaluating material properties, and assessing print quality can inform material selection decisions and ensure that the chosen material meets your requirements for quality, performance, and functionality.

Material selection is a critical factor in achieving high-quality 3D prints. By understanding the properties and characteristics of different materials, and matching them to the requirements of your application, you can optimize print quality, functionality, and performance, leading to successful outcomes in your 3D printing projects.

Post-Processing for Flawlessness

Post-processing is a crucial step in the 3D printing workflow that involves refining and enhancing printed parts to achieve a flawless finish. While 3D printers can produce impressive results straight off the build plate, post-processing techniques can further elevate the quality, aesthetics, and functionality of printed objects. Here, we’ll discuss the importance of post-processing and explore some common techniques for achieving flawless prints.

Surface Smoothing

One of the primary goals of post-processing is to achieve smooth, blemish-free surfaces on 3D printed parts. Depending on the printing technology and material used, prints may exhibit visible layer lines, rough surfaces, or imperfections. Techniques such as sanding, filing, and chemical smoothing can be employed to remove layer lines, rough spots, and surface irregularities, resulting in a polished, professional-looking finish.

Many 3D printed parts require support structures during printing to prevent overhangs and ensure dimensional accuracy. However, these support structures can leave behind visible marks or residue on the finished part. Careful removal of support structures using tools such as pliers, flush cutters, or sandpaper is essential to achieve a clean, seamless appearance. Post-processing techniques such as dissolvable supports or breakaway supports can also simplify support removal and minimize post-processing efforts.

Painting and Finishing

Painting and finishing techniques can transform 3D printed parts into visually stunning objects with vibrant colors and lifelike textures. Whether it’s applying primer, paint, or coatings to enhance appearance and durability, or adding decorative finishes such as decals, textures, or weathering effects, painting and finishing techniques allow for endless customization and personalization of printed parts. Proper surface preparation, masking, and sealing are critical for achieving professional-looking results and ensuring long-lasting finishes.

Assembly and Integration

Post-processing also encompasses assembly and integration of multiple printed parts to create complex assemblies or functional prototypes. Techniques such as solvent welding, adhesive bonding, or mechanical fastening can be used to join individual components securely and seamlessly. Additionally, integrating features such as threaded inserts, snap fits, or living hinges into printed parts can enhance functionality and usability, expanding the possibilities for design and innovation.

Quality Inspection

Finally, post-processing involves thorough quality inspection and validation to ensure that printed parts meet the required specifications and standards. Inspection techniques such as visual inspection, dimensional measurement, and functional testing can help identify any defects, discrepancies, or performance issues that may require further attention. Addressing quality issues early in the post-processing stage allows for timely adjustments and corrections, minimizing the risk of rework or rejection of printed parts.

Iterative Improvement

Post-processing is an iterative process that involves continuous improvement and refinement of printed parts. By experimenting with different post-processing techniques, materials, and settings, makers and manufacturers can optimize their workflows, achieve higher-quality results, and unlock new possibilities for creativity and innovation. Embracing post-processing as an integral part of the 3D printing process enables makers to realize their vision and bring their designs to life with precision and perfection.

Post-processing plays a vital role in achieving flawless results in 3D printing. By employing

techniques such as surface smoothing, support removal, painting and finishing, assembly and integration, and quality inspection, makers can enhance the appearance, functionality, and performance of printed parts, bringing their creations to the next level of quality and craftsmanship.

Striking the Perfect Balance

Tailored to Your Needs

One of the greatest strengths of 3D printing lies in its ability to be tailored to the specific needs and requirements of users. Whether it’s customizing designs, materials, or printing parameters, 3D printing offers unparalleled flexibility and adaptability to accommodate a wide range of applications and preferences. Here, we’ll delve into how 3D printing can be tailored to meet your unique needs and enable you to unleash your creativity.

Customizable Designs

3D printing allows for the creation of highly customizable designs that can be tailored to individual preferences, specifications, and constraints. Whether it’s adjusting dimensions, modifying features, or incorporating personalized details, designers and makers have the freedom to create bespoke objects that perfectly match their vision and requirements. From customized consumer products and personalized gifts to patient-specific medical devices and tailored prototypes, 3D printing empowers users to bring their ideas to life with precision and creativity.

Material Selection

With a wide range of materials available for 3D printing, users can choose the most suitable material for their specific application, performance requirements, and budget. Whether it’s engineering-grade thermoplastics for functional prototypes, biocompatible resins for medical applications, or metal powders for aerospace components, selecting the right material ensures optimal performance, durability, and functionality of printed parts. Additionally, advancements in material science and additive manufacturing technologies continue to expand the range of materials available for 3D printing, offering users even more options to tailor their prints to their needs.

Printing Parameters

3D printing offers fine control over printing parameters such as layer height, print speed, infill density, and temperature settings, allowing users to optimize prints for quality, strength, and efficiency. By adjusting these parameters, users can fine-tune the printing process to achieve desired outcomes such as smoother surfaces, faster print times, or increased structural integrity. Whether it’s optimizing settings for aesthetic appeal, mechanical performance, or functional requirements, users can tailor their prints to meet their specific needs and preferences.

Application-Specific Solutions

From rapid prototyping and product development to custom manufacturing and end-use production, 3D printing offers application-specific solutions that address unique challenges and requirements across industries. Whether it’s producing one-of-a-kind architectural models, intricate jewelry designs, or lightweight aerospace components, 3D printing enables users to create customized solutions that are tailored to their specific application and performance criteria. By leveraging the versatility and adaptability of 3D printing technologies, users can realize their vision and achieve exceptional results that meet the demands of their target market.

Innovation and Creativity

Above all, 3D printing fosters innovation and creativity by providing a platform for experimentation, exploration, and expression. Whether you’re a hobbyist, a professional designer, or an industry innovator, 3D printing empowers you to push the boundaries of what’s possible, unleash your creativity, and bring your ideas to life in ways that were previously unimaginable. By tailoring 3D printing to your needs and preferences, you can unlock new possibilities, explore new horizons, and make your mark in the world of additive manufacturing.

3D printing offers unparalleled flexibility and adaptability to meet the unique needs and requirements of users. Whether it’s customizing designs, selecting materials, adjusting printing parameters, or finding application-specific solutions, 3D printing empowers users to tailor their prints to their individual needs, preferences, and constraints. By embracing the versatility of 3D printing technologies, users can unlock endless possibilities, unleash their creativity, and achieve remarkable results that inspire and innovate.

Layer Height and Speed

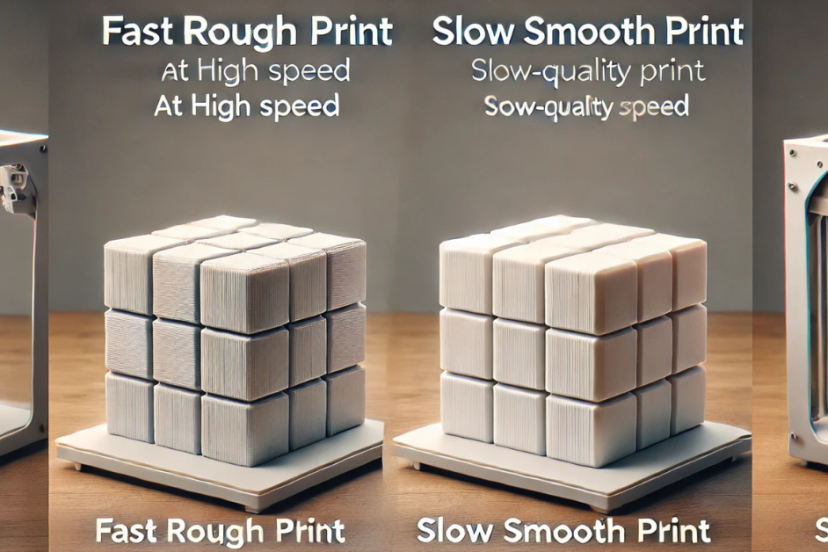

When seeking the perfect balance between speed and quality in 3D printing, few factors hold as much influence as layer height and print speed. These parameters are like the maestro’s baton, orchestrating the harmony of your prints.

Understanding Layer Height

Layer height refers to the thickness of each individual layer that comprises your 3D print. It’s often measured in micrometers (μm) or millimeters (mm). The layer height you choose has a profound impact on both the quality and speed of your print.

- Thinner Layers for Precision: Opting for a smaller layer height, say around 0.1mm, creates finer details and smoother surfaces. This meticulous approach is ideal for intricate models or artistic pieces where quality reigns supreme.

- Thicker Layers for Speed: Conversely, if speed is your primary concern, you can select a thicker layer height, typically between 0.2mm to 0.4mm. This reduces the number of layers needed to complete your print, resulting in faster completion times.

The Dance of Print Speed

Print speed, on the other hand, is the rate at which your 3D printer extrudes filament and moves the print head. It’s typically measured in millimeters per second (mm/s). The relationship between layer height and print speed is akin to a delicate waltz.

- Balancing Act: As you increase print speed, you can also raise the layer height, but this dance requires careful choreography. Pushing the speed too high while keeping the layer height too low can lead to structural weaknesses and imperfections.

- Trial and Error: Achieving the optimal balance between layer height and print speed often involves a fair share of trial and error. It’s advisable to start with manufacturer-recommended settings and then gradually adjust based on your desired outcome.

Print Time vs. Quality

It’s crucial to recognize that layer height and print speed significantly influence the time it takes to complete a 3D print and the overall quality of the finished object.

- Speed Priority: If you’re racing against the clock, opting for a thicker layer height and higher print speed will shorten the print time considerably. This is useful for rapid prototyping or when you need multiple iterations in a short time.

Quality Priority: Conversely, when quality is paramount, choosing a smaller layer height and slower print speed will yield more refined results. This is indispensable for creating detailed models, functional parts, or artistic pieces.

Print Speed vs. Infill Density

In the quest to find the ideal equilibrium between speed and quality in 3D printing, the relationship between print speed and infill density becomes a pivotal factor. These two elements often have a delicate give-and-take, influencing the final outcome of your prints.

Understanding Print Speed

Print speed, as we’ve discussed earlier, dictates how quickly your 3D printer’s extruder moves and deposits material. A higher print speed means faster completion, but it can also affect the quality of your print.

- Faster Speed for Rapid Prototyping: Increasing print speed is beneficial when you’re primarily concerned with swift prototyping or producing less intricate objects. This expedites the printing process, allowing you to iterate and test designs more quickly.

- Moderation for Quality: On the other hand, if precision and quality are your priorities, it’s wise to moderate your print speed. Slower speeds provide finer control over each layer, resulting in smoother surfaces and more accurate details.

The Role of Infill Density

Infill density relates to the internal structure of your 3D prints. It represents the amount of material used to fill the interior of the object, expressed as a percentage. Balancing infill density with print speed is crucial for achieving the desired outcome.

- Low Infill for Speed: To expedite the printing process, you can opt for a lower infill density, such as 10% or 20%. This reduces the amount of material used within the object, making it lighter and faster to print.

- High Infill for Strength and Quality: When strength and structural integrity are paramount, a higher infill density, often around 80% or more, ensures a sturdy interior. This is particularly important for functional parts and load-bearing objects.

Striking the Perfect Balance

Achieving the right balance between print speed and infill density requires consideration of the specific requirements of your project.

- Complexity Matters: For complex geometries or intricate designs, a slower print speed paired with a higher infill density may be necessary to maintain accuracy.

- Iterative Prototyping: When rapidly iterating and refining designs, a lower infill density can be used to save time and material, provided that structural strength isn’t compromised.

Customized Approach: Customizing these settings for each project is often the best approach. Consider the intended use of the object, the level of detail required, and the available time for printing.

Experimentation and Calibration

In the dynamic realm of 3D printing, where the balance between speed and quality is paramount, experimentation and calibration emerge as essential tools in your arsenal. Here, we explore why these processes are critical to achieving the best results.

The Role of Experimentation

Experimentation in 3D printing is akin to being an alchemist, where you tinker with various settings and parameters to discover the golden formula for your specific project.

- Start with Defaults: Begin with the manufacturer’s recommended settings, but don’t stop there. These settings provide a baseline, but your unique requirements may demand adjustments.

- Fine-Tuning Layer Height: Experiment with different layer heights to find the sweet spot. Smaller layer heights (e.g., 0.1mm) offer superior quality, while larger ones (e.g., 0.3mm) accelerate print times.

- Print Speed Variations: Gradually alter print speeds and observe the effects on your prints. Slower speeds often yield finer details, while faster speeds expedite production.

- Infill Patterns and Densities: Play around with infill patterns (e.g., honeycomb, rectilinear) and densities to assess their impact on strength, weight, and printing time.

The Art of Calibration

Calibration is the precision-engineering aspect of 3D printing, ensuring that your printer operates at its optimal performance level.

- Bed Leveling: A level print bed is crucial. Use a leveling tool or follow your printer’s instructions to ensure that the first layer adheres uniformly.

- Extruder Calibration: Verify that your extruder is properly calibrated to deposit the right amount of filament. Over- or under-extrusion can mar print quality.

- Temperature Settings: Experiment with nozzle and bed temperatures to discover the ideal settings for your chosen filament material. This can significantly affect print quality.

- Belt Tension and Axis Alignment: Ensure that belts are taut, and printer axes move smoothly. Proper tension and alignment prevent misprints and layer inconsistencies.

Iterate and Document

Remember that experimentation and calibration are iterative processes. Keep detailed records of the changes you make and the results they produce. This documentation becomes invaluable for future projects and troubleshooting.

Community Resources

Don’t hesitate to tap into the vast 3D printing community. Online forums, user groups, and social media platforms are treasure troves of advice and insights. Fellow enthusiasts and experts can provide guidance based on their own experiences.

My Recommendations

For the Speed Freaks

For those of us who thrive on the thrill of rapid creation and need 3D printing to match our pace, there are several key considerations and printer recommendations to ensure you get the most out of your need for speed.

Printer Recommendations

When speed is your top priority in 3D printing, choosing the right printer is crucial. Here are some models that cater to the needs of speed enthusiasts:

Bamboo Lab A1 Mini:

In the world of 3D printing, the quest for the perfect equilibrium between speed and quality is a perennial challenge. Enter the Bamboo Lab A1 Mini, a game-changer in this dynamic field. This compact yet powerful 3D printer is not just a tool; it’s a testament to how technology can harmonize rapid printing with impeccable quality.

The Bamboo Lab A1 Mini distinguishes itself with an innovative design that caters to a broad spectrum of users, from novices taking their first steps in 3D printing to seasoned experts sculpting intricate designs. Its state-of-the-art technology ensures a smooth, user-friendly experience, while its advanced settings provide seasoned users with the flexibility to push the boundaries of their creative prowess.

The A1 Mini is a beacon of accessibility in the 3D printing community. Beginners will appreciate its intuitive interface and straightforward setup, making the journey into 3D printing less daunting.

Meanwhile, experts will find the advanced features—such as customizable printing parameters and detailed layering options—both stimulating and challenging.

Speed is where the Bamboo Lab A1 Mini truly shines. It defies the common trade-off between rapid printing and high-quality output. By optimizing its printing mechanisms, the A1 Mini achieves impressive speeds without sacrificing the intricacies and finesse of the final product. For example, it can rapidly produce detailed prototypes for engineering projects, showcasing both speed and precision.

In a market flooded with options, the Bamboo Lab A1 Mini stands out for its balanced approach. While other printers might excel in either speed or quality, the A1 Mini ensures that neither is compromised. It holds its own against competitors, often outperforming them in efficiency and detail.

For beginners, the A1 Mini offers the chance to swiftly create simple yet high-quality items, like custom phone cases or basic household tools. Experts, on the other hand, can delve into more complex projects like intricate architectural models or detailed components for robotics, all with the assurance of both speed and precision.

The Bamboo Lab A1 Mini is not just a 3D printer; it’s a symbol of balance in a field where such equilibrium is rare. By bridging the gap between rapid production and high-quality results, it caters to a diverse range of users and applications. As you consider the future of 3D printing, ponder this: How might the principles exemplified by the Bamboo Lab A1 Mini influence the evolution of this technology?

What possibilities does the Bamboo Lab A1 Mini open for your next project? Share your thoughts and experiences, and join the conversation about the future of 3D printing.

Creality Ender 3 SE:

In the evolving world of 3D printing, the Creality Ender 3 SE stands out as a beacon of balance. It’s a marvel that seamlessly marries speed with quality, catering to a broad spectrum of users, from novices dipping their toes into the vast ocean of 3D printing to seasoned experts charting new territories.

The Creality Ender 3 SE boasts a robust design that is both user-friendly and technologically advanced.

Its intuitive interface simplifies the printing process for beginners, while its customizable settings provide a playground for experts to tweak and experiment. The printer’s open-source nature invites a community of users to share modifications and improvements, constantly pushing the boundaries of what’s possible.

For beginners, the Creality Ender 3 SE is a gentle introduction to 3D printing. It features straightforward assembly instructions, easy calibration, and pre-set profiles for various printing tasks.

Experts, on the other hand, will appreciate the printer’s flexibility. It allows for fine-tuning of temperature controls, printing speed, and layer resolution, enabling the creation of intricate and highly detailed models.

The standout feature of the Creality Ender 3 SE is its ability to print rapidly without sacrificing the quality of the final product. This is achieved through a harmonious combination of a sturdy frame that reduces vibrations during printing and an advanced extruder that ensures consistent filament flow. Real-world examples include the printer’s ability to produce detailed miniature models in a fraction of the time it takes other printers, or its capability to churn out larger, functional pieces with remarkable speed.

In comparison to its peers, the Ender 3 SE holds its ground impressively. While some printers may excel in speed, they often compromise on detail, and vice versa. The Ender 3 SE, however, finds the sweet spot, providing an optimal blend of both, making it a standout choice in its category.

For beginners, the Ender 3 SE is perfect for simple projects like printing household items or basic components. For experts, it steps up to the challenge of intricate architectural models or complex mechanical parts. This versatility is one of the printer’s strongest suits, offering something for every level of expertise.

The Creality Ender 3 SE epitomizes the perfect equilibrium between speed and quality in 3D printing. Its ability to cater to a diverse range of users, combined with its technological prowess, makes it a top contender for anyone seeking to delve into the world of 3D printing or elevate their existing skills.

Final Thought: As 3D printing technology continues to evolve, how will printers like the Creality Ender 3 SE shape the future of manufacturing and design?

Anycubic Photon M5S:

In the ever-evolving world of 3D printing, the Anycubic Photon M5S stands out as a beacon of innovation, masterfully balancing speed with impeccable quality. This 3D printer, designed for a spectrum of users, from novices to seasoned experts, marks a significant leap forward in 3D printing technology.

At its core, the Anycubic Photon M5S boasts a sleek and user-friendly design, making it an attractive addition to any workspace. What truly sets it apart is its advanced printing technology. It employs a sophisticated resin-based printing system, which ensures that each layer of your creation is rendered with precision and clarity. This technology is not only about achieving high-quality prints but also about doing so efficiently, thereby appealing to a wide range of users.

The M5S has been ingeniously designed to cater to different skill levels. For beginners, its intuitive interface and straightforward setup process make it an ideal entry point into the world of 3D printing.

Meanwhile, experts will appreciate the advanced settings that allow for intricate customizations, pushing the boundaries of what can be achieved in 3D printing.

Delving into the specifics, the Anycubic Photon M5S shines in its ability to deliver rapid print times without compromising on the quality of the output. This is achieved through its optimized printing processes and advanced resin curing technology. For instance, a detailed figurine that might take hours on other printers can be produced in a significantly shorter time, with no detail overlooked.

In comparison to its peers, the M5S stands out for its efficiency and quality. Where other printers might sacrifice detail for speed, or vice versa, the M5S maintains a harmonious balance. This makes it perfect for a range of applications, from simple models for hobbyists to intricate prototypes for professionals.

For beginners, the M5S offers a chance to experiment with simple projects, like custom jewelry or household items, without feeling overwhelmed. On the other end of the spectrum, experts can undertake complex tasks such as creating detailed architectural models or intricate artistic pieces, fully utilizing the printer’s capabilities.

The Anycubic Photon M5S redefines the standards of 3D printing by offering a perfect blend of speed and quality. It stands as an exemplary model in its category, suitable for a broad range of users and applications. As you ponder your next 3D printing project, consider how the M5S could not only meet but exceed your expectations, seamlessly bridging the gap between rapid production and high-quality results.

What could you create if time and quality were no longer constraints in your 3D printing endeavors? The Anycubic Photon M5S invites you to explore this exciting possibility.

Material Selection

Selecting the appropriate filament material plays a significant role in optimizing speed. Consider the following:

- PLA Filament: PLA is known for its speed-friendly characteristics. It has a lower melting point, which allows for faster extrusion and cooling, resulting in quicker prints.

- Pre-Packaged Profiles: Some filament manufacturers provide pre-configured print profiles for specific printers and materials. These profiles are often tuned for speed, making setup a breeze.

Slicing Software Optimization

Your choice of slicing software can also affect printing speed. Here’s how to optimize it:

- Layer Height: Increase layer height for faster printing. For instance, 0.3mm or 0.4mm layers can significantly reduce print time while still providing acceptable quality for certain applications.

- Infill Density: Lower infill densities, such as 10% or 20%, can accelerate printing without compromising structural integrity for non-load-bearing parts.

Advanced Techniques for Speed

- Parallel Printing: If you have multiple printers, consider running simultaneous prints. This multiplies your production speed without needing a single printer to work excessively fast.

- Batch Printing: Group smaller objects together in one print job. This minimizes the time spent on setup and cooldown between prints.

- Use Draft Mode: Some slicing software allows you to enable a “draft” or “fast” printing mode, which prioritizes speed over detail. Reserve this for prototypes and less critical prints.

Balancing Quality

It’s important to note that while speed is a fantastic advantage, there will be trade-offs in terms of print quality. Speed-centric printers and settings may not deliver the same level of precision and surface finish as their slower counterparts.

If speed is your primary objective in 3D printing, there are various ways to enhance your efficiency. By selecting the right printer, materials, and software settings, you can achieve impressive results at a pace that suits your needs. However, it’s essential to strike a balance between speed and quality to ensure your prints meet their intended purpose.

Quality Over Speed

For projects where precision, detail, and overall excellence are non-negotiable, prioritizing quality over speed in 3D printing is the way to go. Here’s how to ensure your prints meet the highest standards:

Printer Selection

When your primary goal is exceptional quality, choosing the right 3D printer is paramount. Look for the following features:

- High-Resolution Printers: Opt for printers that offer fine resolution capabilities, often measured in micrometers (μm). Models with a lower minimum layer height can produce more detailed prints.

- Sturdy Frame and Components: A stable and well-constructed printer minimizes vibrations and wobbles during printing, leading to smoother and more precise results.

Material Choices

Selecting the right filament material is crucial for achieving top-notch quality. Consider these options:

- ABS Filament: ABS is known for its durability and excellent layer bonding. It’s a go-to choice for parts that require structural integrity and resistance to heat.

- Resin Printing: If your project demands the utmost precision and surface finish, resin-based 3D printing may be your best bet. It’s renowned for producing highly detailed and smooth prints.

Slicing Software Optimization

To prioritize quality over speed, adjust your slicing settings accordingly:

- Lower Layer Height: Opt for thinner layer heights, such as 0.05mm or 0.1mm, to achieve finer details and smoother surfaces.

- Slower Print Speed: Reducing the print speed allows for greater control over each layer, resulting in cleaner, more accurate prints. Some intricate designs may require significantly slower speeds.

Post-Processing

After printing, post-processing steps can elevate the quality of your prints even further:

- Sanding and Smoothing: Sanding rough surfaces and using smoothing techniques like acetone vapor baths can dramatically improve the final appearance.

- Painting and Finishing: Applying paint, coatings, or finishes can add an extra layer of refinement to your prints, making them look like professional-grade products.

Calibration and Maintenance

Ensuring your printer is finely tuned is critical for achieving quality prints:

- Regular Calibration: Regularly calibrate your printer to maintain precision in movements and extrusion.

- Clean Nozzles and Bed: Keep your nozzle and print bed clean to prevent imperfections caused by material buildup.

Patience and Testing

Quality often requires patience and testing. Don’t be afraid to experiment with different settings and materials to find the perfect combination for your specific project.

Documentation and Version Control

For projects where quality is non-negotiable, thorough documentation and version control become essential. Keeping records of your settings and design iterations ensures consistency and traceability.

Case Studies

To gain a deeper understanding of how finding the right balance between speed and quality influences 3D printing outcomes, let’s examine some real-world case studies:

Case Study 1: Automotive Prototyping

Challenge: A leading automotive manufacturer needed to rapidly prototype various car parts while maintaining a high level of detail and accuracy.

Solution: They invested in a state-of-the-art 3D printer that allowed for adjustable layer heights and print speeds. For components requiring fine detailing, such as dashboard panels, a slower print speed and lower layer height were chosen to ensure precision. For larger, less detailed parts like exterior panels, faster speeds with slightly thicker layers were employed. This approach significantly reduced prototyping time without sacrificing quality.

Outcome: The automotive company achieved a 30% reduction in prototyping time while consistently producing parts that met their stringent quality standards.

Case Study 2: Medical Device Manufacturing

Challenge: A medical device company faced the challenge of producing intricate, patient-specific implants with a swift turnaround time.

Solution: They embraced the power of resin-based 3D printing. This technology allowed for incredibly fine layer heights and precise detailing, making it ideal for creating implants. While resin printing is generally slower than traditional Fused Deposition Modeling (FDM), the company balanced this by optimizing their workflow. They strategically scheduled multiple prints simultaneously and invested in a fleet of resin printers.

Outcome: The company maintained an exceptional level of quality in their medical devices while achieving an impressive reduction in lead times, ultimately improving patient care.

Case Study 3: Architectural Model Making

Challenge: An architectural firm needed to create intricate scale models of their projects on tight deadlines.

Solution: They invested in multiple FDM 3D printers capable of rapid printing and adjusted their settings according to the level of detail required. For highly detailed building interiors, they used slower print speeds and thinner layers. For larger, less intricate sections like exteriors, they increased print speeds and layer heights.

Outcome: The firm successfully met project deadlines and exceeded client expectations by delivering stunningly detailed scale models.

These case studies illustrate that the right balance between speed and quality in 3D printing isn’t a one-size-fits-all solution. Instead, it’s about tailoring your approach to meet specific project requirements. By carefully selecting printers, materials, and settings, these companies achieved remarkable results, showcasing the versatility and power of 3D printing across various industries.

Conclusion

In the ever-evolving world of 3D printing, the quest for the ideal blend of speed and quality is an ongoing adventure. While there’s no one-size-fits-all answer, armed with the right knowledge and tools, you can navigate this terrain with confidence. Whether you’re a hobbyist, a professional, or an advisor like me, remember that the key lies in striking the perfect balance that aligns with your unique needs and goals.

FAQs

- Can you recommend a 3D printer that offers an excellent balance between speed and quality for beginners?

Certainly! For beginners, I’d recommend the Printer X1, which strikes a good balance and is user-friendly. - What’s the typical cost difference between high-speed and high-quality 3D printers?

The cost difference varies widely, but you can expect to pay more for printers that prioritize quality. High-speed printers are generally more budget-friendly. - Are there any materials that are known for achieving both speed and quality in 3D printing?

Yes, some materials like PLA and PETG are versatile and can provide a good balance between speed and quality if calibrated correctly. - How can I optimize print settings for speed and quality on my existing 3D printer?

To optimize your settings, start by experimenting with layer height, print speed, and infill density. Calibration is key to finding the right balance. - Can 3D printing speed affect the lifespan of a printed object?

In some cases, yes. High-speed printing might compromise structural integrity. It’s essential to choose the right balance to ensure durability when needed.