Unveiling the Elite: Your Ultimate Guide to the Best Resin 3D Printers of 2024

In the kaleidoscopic world of 3D printing, where innovation and creativity intersect, resin printers have carved out a niche for themselves, captivating hobbyists and professionals alike. The best 3D resin printer is more than a machine; it’s a gateway to transforming the ethereal into the tangible, where every detail matters, and every print tells a story.

But what truly defines the “best” in a market brimming with options? Is it the lightning-fast speeds that defy the patience of creation, or the microscopic precision that captures the essence of your imagination? Or perhaps, it’s the intuitive ease of use that makes complex technology accessible to all? The answer lies in a harmonious blend of these traits, tailored to the needs and aspirations of its user.

Imagine a printer that not only brings your most intricate designs to life but does so with a finesse that breathes life into every layer. It’s about striking the perfect balance between speed and detail, ensuring that not a minute is wasted nor a detail overlooked. But beyond the hardware lies the soul of the printer: software that speaks your language, a supportive community that shares your passion, and an ecosystem that nurtures your creativity.

The best 3D resin printer is the one that fits seamlessly into your workflow, empowering you to push the boundaries of what’s possible. Whether you’re crafting bespoke jewelry, precision engineering parts, or fantastical tabletop miniatures, the right printer is your faithful companion on this journey of creation. It’s about finding that perfect match where every print feels like a masterpiece, and every masterpiece sparks a new idea.

So, as we venture into the heart of this guide, remember: the best 3D resin printer is not just a tool; it’s the key to unlocking a world where your creativity knows no bounds. Join me as we explore the leading contenders, each with its own story to tell, in the quest to find the one that resonates with your spirit of innovation and creativity.

Why Resin?

In the dynamic arena of 3D printing, where each technology vies for attention, resin 3D printing stands out for reasons that resonate with both the artist and the engineer. But why do enthusiasts and professionals alike gravitate towards resin? The allure of resin lies in its ability to achieve the unachievable, turning dreams into reality with precision and speed that other technologies struggle to match.

Precision That Captures Every Detail: Imagine the delicate wings of a dragonfly, with every vein detailed in its ethereal beauty. Resin printers make this possible. The technology behind resin printing allows for layer resolutions that are so fine, the end result often requires a magnifying glass to fully appreciate the intricacy. This is the realm where the only limit to detail is your imagination.

A Finish Unparalleled in Smoothness: Beyond the precision, resin prints emerge with a surface finish that is astonishingly smooth, often eliminating the need for post-processing. This is especially important for applications where aesthetics are paramount, such as jewelry design or figurine production. The smooth finish also proves beneficial in functional parts, where surface friction needs to be minimized.

Speed That Keeps Pace with Your Creativity: In a world where time is often of the essence, resin printing technologies offer speeds that can keep pace with your flow of ideas. Advances in resin printer designs and the development of new, faster-curing resins mean that what used to take hours can now be accomplished in minutes. This efficiency opens up new possibilities for rapid prototyping, allowing designers and engineers to iterate faster than ever before.

Versatility for Various Applications: Resin printers are not one-trick ponies; they excel in a wide range of applications. From dental and medical models to intricate jewelry and detailed gaming miniatures, the versatility of resin 3D printing is a testament to its adaptability across sectors. With a growing library of resins, each with unique properties like flexibility, durability, or transparency, the potential applications for resin printing continue to expand.

A Community of Innovators: Behind every great technology lies a community of passionate individuals. The resin 3D printing community is a vibrant ecosystem of makers, designers, and hobbyists who share a common passion for pushing the boundaries of what’s possible. This community-driven innovation leads to constant improvements in resin printing techniques, materials, and software, ensuring that the technology continues to evolve and adapt to the needs of its users.

In essence, the question isn’t “Why resin?” but rather, “Why not?” With its unmatched detail, superior surface finish, rapid printing speeds, and versatility, resin 3D printing offers a compelling proposition for anyone looking to bring their visions to life. Whether you’re a seasoned professional or just beginning your journey into the world of 3D printing, the world of resin offers a rich canvas for exploration and creativity.

Factors to Consider

Selecting the best resin 3D printer is akin to choosing the right partner for a dance. It’s about finding that perfect match that complements your rhythm, style, and aspirations. Here are the pivotal considerations that will guide you through this decision-making waltz:

- Speed: Speed in resin printing doesn’t just mean how fast the printer can move. It encompasses the time from the moment you hit ‘print’ to the moment you hold a finished piece. Consider printers that optimize this entire process, reducing waiting times and increasing your productivity. But remember, speed should not compromise the quality. The best printers balance these two aspects beautifully, ensuring quick results without losing the fine detail that makes resin printing stand out.

- Print Quality: When we talk about quality in resin 3D printing, we’re referring to the printer’s ability to reproduce intricate details with clarity and precision. The resolution of a printer, measured in microns, plays a crucial role here. Lower numbers mean higher resolution, but it’s also about how well the printer manages layers and curing. Look for printers that offer a fine balance between layer height and exposure control, as these will significantly impact the finesomeness of your prints.

- Ease of Use: A resin 3D printer should not require a degree in rocket science to operate. From intuitive software interfaces to streamlined setup processes and reliable support systems, ease of use is paramount. Consider printers that offer a user-friendly experience at every step. Features like automatic resin feeding, easy bed leveling, and guided cleaning processes can transform your printing experience from tedious to enjoyable.

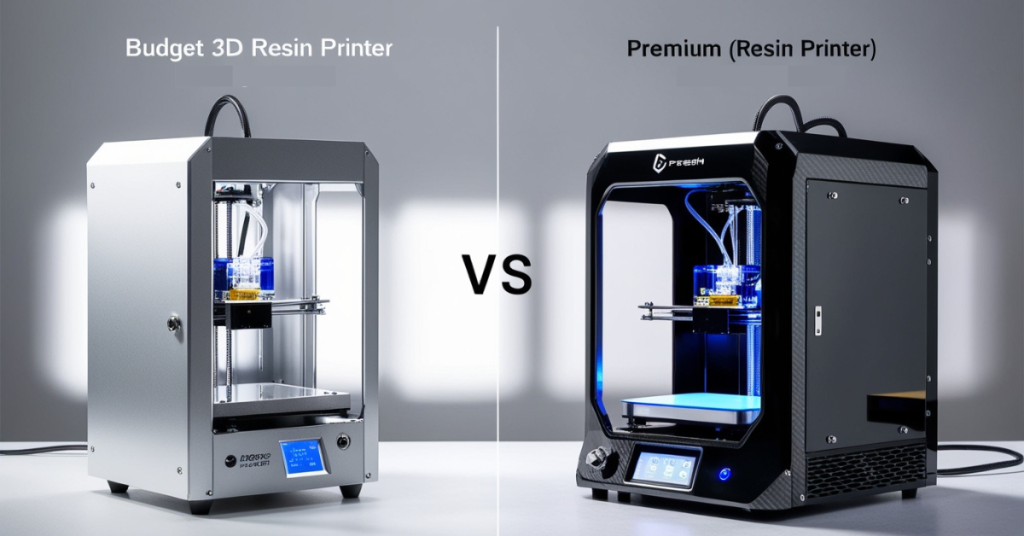

- Price to Performance Ratio: The cost of a resin 3D printer is not just its purchase price. You must consider the ongoing costs of materials, replacement parts, and even electricity. Assessing the price to performance ratio involves looking at the total cost of ownership alongside the printer’s capabilities. Seek out printers that offer durability, efficient resin use, and minimal maintenance needs. It’s about investing in a printer that will serve you faithfully in the long run, offering both quality and reliability without draining your wallet.

- Materials Compatibility: The versatility of your resin 3D printer is significantly determined by the types of resins it can process. From standard resins to specialized ones for toughness, flexibility, or transparency, your printer’s ability to handle a wide range of materials opens up a universe of possibilities for what you can create. Look for printers compatible with third-party resins, as this can not only reduce your material costs but also provide you with a broader palette for your projects.

- Safety Features: Resin printing involves chemicals that require careful handling. Printers designed with safety in mind include features like built-in ventilation or air filtration systems, spill-proof resin tanks, and UV-blocking covers. These features not only protect you but also ensure a more pleasant and safe working environment.

- Community and Support: Last but certainly not least, the community and manufacturer support surrounding a printer can greatly enhance your experience. A vibrant community can provide tips, troubleshooting advice, and inspiration for your projects. Manufacturer support is also crucial for resolving any technical issues. A company that offers responsive and helpful customer service, alongside a wealth of online resources, can make all the difference in your 3D printing journey.

Choosing the best resin 3D printer is a journey of balancing these factors against your personal needs and goals. Whether you prioritize speed and efficiency, detail and quality, or perhaps a blend of all these elements, understanding these key considerations will help you make a choice that brings your creative visions to life with precision and ease.

Top Picks for Resin 3D Printers

In the quest for the best resin 3D printer, a few models stand out from the crowd, each excelling in different areas. Whether you’re a hobbyist seeking precision for intricate models or a professional needing reliability and speed, here’s a curated list of printers that have garnered acclaim for their performance, ease of use, and innovation.

The Speed Demon: Anycubic Photon Mono X

The Anycubic Photon Mono X remains a standout choice for those prioritizing speed without sacrificing quality. Its impressive monochrome LCD speeds up the printing process significantly while maintaining high-resolution outputs. Ideal for professionals and hobbyists alike, this printer excels in delivering quality prints swiftly, making it a reliable tool in any creator’s arsenal.

The Detail Master: Elegoo Mars 4 MSLA

Replacing the Elegoo Mars 3 Pro, the Elegoo Mars 4 MSLA brings enhanced capabilities to the table. This model boasts a new monochrome LCD that provides even higher resolution and more precise UV light control, resulting in exceptionally detailed prints. The Mars 4 is perfect for those who need ultra-fine details for intricate models, jewelry, or dental work, bridging the gap between professional needs and accessible technology.

The Budget-Friendly Choice: Phrozen Sonic Mini 8K

Upgrading from the Sonic Mini 4K, the Phrozen Sonic Mini 8K offers an even more impressive resolution at a still accessible price point. This printer is designed for those who do not want to compromise on the quality of their detailed projects but must adhere to a tighter budget. Its 8K resolution capabilities ensure that even the smallest features are sharp and clear, making it an excellent choice for detailed figurines and complex educational models.

The All-Rounder: Formlabs Form 4

The Formlabs Form 4 is the latest iteration, succeeding the Form 3 with improvements in speed, precision, and user interface. This model uses advanced Low Force Stereolithography (LFS) technology, which enhances print consistency and reduces the forces exerted on the model during the printing process. With a robust ecosystem of resin materials and a user-friendly setup, the Form 4 is perfect for businesses and enthusiasts who demand the best balance of functionality and innovation.

The Innovator: Prusa SL1S Speed

The Prusa SL1S Speed is designed for users who value innovation and efficiency. With its high-speed monochrome LCD and fine-tuned optics, it significantly reduces layer curing time, allowing for faster print speeds without a drop in quality. Coupled with Prusa’s reputation for reliability and excellent customer support, the SL1S Speed is perfect for those who seek the cutting edge in resin printing technology.

Making the Most of Your Resin 3D Printer

Owning a resin 3D printer is just the beginning. To truly excel and make the most of this powerful tool, a combination of proper maintenance, creative exploration, and continuous learning is key. Here’s how to ensure that your printer not only lasts longer but also helps you bring even the most ambitious projects to life.

Maintenance and Care

Regular maintenance is the backbone of printer longevity and consistent print quality. Here are essential practices to integrate into your routine:

- Regular Cleaning: Post-processing and spills are part of the resin printing process. Keeping your printer clean, including the vat, build plate, and outer surfaces, prevents contamination and ensures smooth operation. Use isopropyl alcohol to clean the vat and build plate, and ensure you handle liquid resin safely, wearing gloves and protective eyewear.

- Vat and FEP Film Care: The FEP film at the bottom of the resin vat is crucial for successful prints but can wear out or get damaged. Inspect it regularly for scratches or cloudiness and replace it as needed to maintain print quality and prevent failures.

- UV Light Source Maintenance: The UV light source is essential for curing resin. Keep it free from dust and resin spillage. For printers using LCD screens, check for pixel health and replace the screen if you notice dead pixels, as they can affect the details of your prints.

Optimizing Print Settings

Finding the optimal settings for your resin and model can significantly enhance print quality:

- Layer Height and Exposure Times: Experiment with layer height and exposure times to find the perfect balance between speed and detail for your specific resin.

- Support Structures: Mastering support placement is crucial in resin printing. Use your printer’s software to generate supports, but don’t shy away from manually adding or removing supports for better results and easier post-processing.

- Hollowing Models: To save resin and reduce print times, consider hollowing larger models. Just remember to add drainage holes to prevent trapped uncured resin.

Expanding Your Material Horizons

Resin technology is constantly advancing, with new formulations hitting the market:

- Experiment with Different Resins: From tough and durable to flexible or castable resins, expanding your material usage can open new avenues for projects and applications.

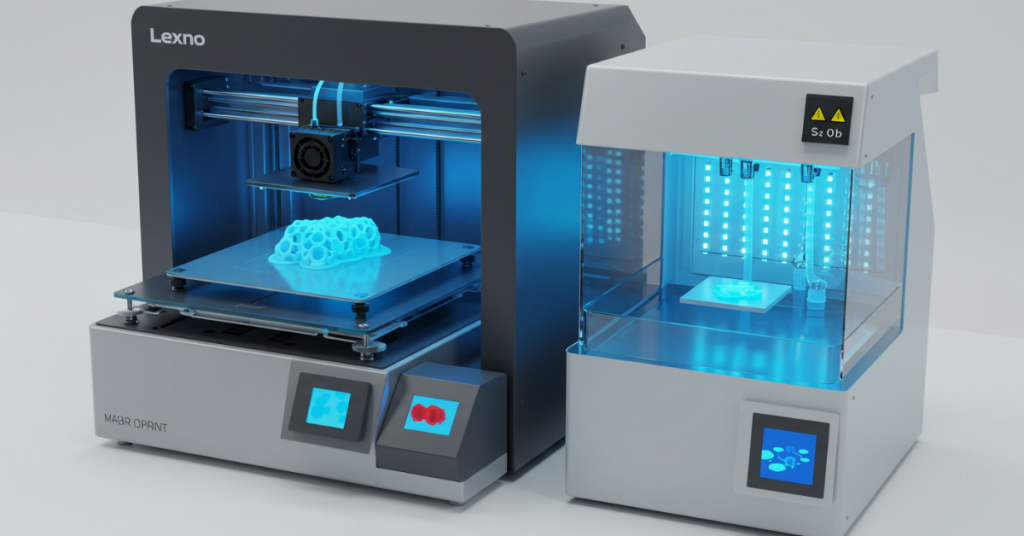

- Post-Curing Properly: Different resins have different post-curing requirements. Invest in a good UV curing station and follow the manufacturer’s recommendations for curing times to achieve the best material properties.

Engaging with the Community

The resin printing community is a treasure trove of knowledge, inspiration, and support:

- Join Forums and Social Media Groups: Engage with other resin printing enthusiasts to share experiences, troubleshoot issues, and get feedback on your projects.

- Follow Tutorials and Workshops: Take advantage of online tutorials and workshops to learn new techniques and keep up with the latest advancements in resin printing.

Innovative Projects to Push Your Limits

Finally, the best way to make the most of your resin 3D printer is to challenge yourself with projects that push the boundaries of what you believe is possible:

- Custom Jewelry: Utilize the precision of resin printing to create intricate jewelry designs that would be difficult to replicate with traditional manufacturing techniques.

- Detailed Miniatures and Models: Whether for gaming, collecting, or prototyping, the detail achievable with resin printers is unmatched, allowing for complex, scale models and figurines.

- Functional Parts: Explore the use of durable and specialized resins to print functional parts for gadgets, machines, or even medical models.

Embracing these practices and challenges not only enhances the longevity and performance of your resin 3D printer but also elevates your skills and creativity. The journey with resin 3D printing is one of continuous learning and exploration, where each print can be a masterpiece and every challenge a stepping stone to mastery.

Conclusion

Embarking on the resin 3D printing journey is akin to unlocking a door to endless possibilities. As we’ve navigated through the realms of choosing the best resin 3D printer, understanding its profound impact, and mastering its use, one thing becomes abundantly clear: the power to bring your most ambitious visions to life lies within your grasp. Whether you’re drawn to the unparalleled detail, the astonishing speed, or the sheer versatility of materials and applications, resin 3D printing offers a unique canvas for your creativity.

Choosing the right printer, however, is just the beginning. As you delve deeper into the world of resin printing, you’ll discover that each project is a learning experience, each challenge an opportunity to grow. The journey is as much about the creations you bring to life as it is about the insights you gain and the community you become a part of. From the meticulous care and maintenance of your printer to the exploration of new materials and techniques, every step you take is a step towards mastering this captivating form of art and engineering.

But remember, the best resin 3D printer is not just about the specifications or the price tag; it’s about how well it aligns with your needs, ambitions, and the stories you want to tell. It’s about finding that perfect partner in creation that not only meets your expectations but inspires you to push the boundaries of what you thought was possible.

So, as you stand at the precipice of your next creative endeavor, armed with the knowledge and insights from this guide, embrace the possibilities that resin 3D printing holds. Let your creativity flow, challenge the limits of detail and precision, and join a community of innovators who share your passion for bringing the impossible to life.

The world of resin 3D printing is vast and ever-evolving, filled with opportunities to create, innovate, and inspire. Whether you’re a seasoned professional or a curious newcomer, there’s never been a better time to explore this remarkable technology. Let your journey begin today, and may your creations not only reflect your vision but inspire others to embark on their own journeys of discovery and innovation.

FAQs

- What makes resin 3D printers faster than others?

Resin 3D printers, especially those utilizing modern LCD and DLP technology, are often faster than their FDM counterparts due to the way they cure resin. They can cure entire layers of resin simultaneously, rather than tracing each layer point by point. This, combined with the development of quicker-curing resins and more efficient light sources, significantly reduces print times, making resin printers ideal for rapid prototyping and high-detail projects.

- How do I maintain my resin 3D printer?

Maintaining your resin 3D printer involves regular cleaning, vat and FEP film care, and ensuring the UV light source remains effective. After each print, clean the build plate and vat with isopropyl alcohol to remove uncured resin. Check the FEP film for any signs of wear or damage and replace it as needed. Also, keep the UV light source clean and free from resin. Regular firmware updates and mechanical checks will keep your printer running smoothly. - Can I use any resin with my 3D printer?

While many resin 3D printers are compatible with third-party resins, it’s essential to check your printer’s specifications and recommendations. Different resins have varying properties and curing times, which can affect print quality and success. Some printers are calibrated for specific resin types, so using an incompatible resin might result in poor print quality or even damage the printer. Always perform a test print when trying a new resin brand or type. - What are some common mistakes to avoid in resin 3D printing?

Common mistakes include not properly preparing the build platform, resulting in adhesion issues; not shaking the resin bottle before use, leading to inconsistent prints; ignoring the importance of supports, which can cause parts of the model to fail; and inadequate post-processing, which can leave the print sticky or uncured. Learning the nuances of your specific printer and resin type can help avoid these pitfalls. - How can I decide between a laser and an LCD resin 3D printer?

The choice between a laser (SLA) and an LCD (MSLA) resin 3D printer depends on your specific needs. SLA printers use a laser to cure the resin, offering high precision and quality, making them suitable for applications requiring intricate details. MSLA printers use an LCD screen to cure entire layers at once, offering faster print times but sometimes at the expense of the ultimate detail that SLA can achieve. Consider your priority between detail and speed, as well as your budget, as SLA printers tend to be more expensive.