Top 5 3D Printers of 2024: Finding the Best Model for Your Projects

As the new year unfolds, the evolution of 3D printing technology continues to astound us, offering more sophisticated, user-friendly, and efficient models than ever before. Whether you’re setting up a new design studio, upgrading your home workshop, or integrating cutting-edge tools into your educational curriculum, selecting the right 3D printer is crucial for success. In 2024, a multitude of models are vying for the title of ‘best in class,’ each boasting unique features that cater to diverse printing needs.

Why is choosing the right 3D printer so critical this year? With advancements in print speed, resolution, and material compatibility, today’s printers can significantly impact the quality and scope of your projects. Moreover, as the technology becomes more accessible, it’s vital to discern which features truly enhance your creative process versus those that are merely hype.

In this guide, we will explore the top 5 3D printers that stand out in 2024. These models are not just machines; they are gateways to expanding your creative horizons, pushing the boundaries of what you can achieve with 3D printing. From reliable workhorses suitable for beginners to high-end machines that promise to transform professional workflows, we’ll help you navigate the landscape to find the best model that fits your projects’ demands and your budget.

Let’s dive into the world of 3D printing and discover which models are leading the pack in 2024, setting new standards for performance, precision, and usability.

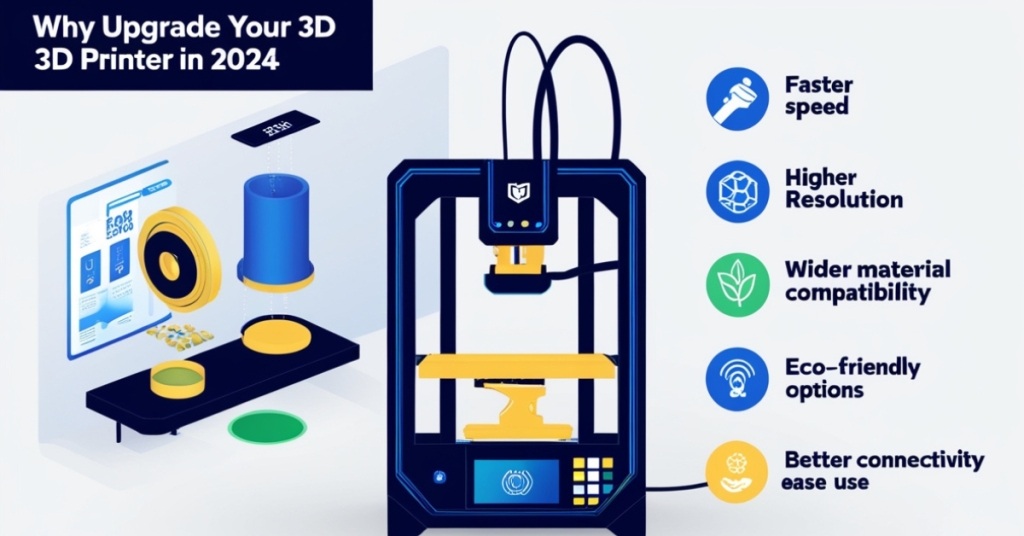

Why Upgrade Your 3D Printer in 2024?

In the fast-paced world of technology, staying current is key, and the field of 3D printing is no exception. As we step into 2024, the advancements in 3D printing technology present compelling reasons to consider upgrading your equipment. But why should you upgrade your 3D printer this year? Let’s explore the driving factors that make an upgrade not just a luxury, but a necessity for anyone serious about their 3D printing endeavors.

Cutting-Edge Technology

The latest models of 3D printers come equipped with state-of-the-art technology that offers superior precision, increased speed, and greater material flexibility. These advancements allow for finer details and smoother finishes, which are essential for professional-quality projects. Whether you are a designer, engineer, or hobbyist, the ability to produce intricately detailed objects with reliability can significantly enhance the scope of what you can create.

Improved User Experience

2024’s 3D printers boast enhancements that significantly improve the user experience. From intuitive touchscreens to sophisticated software that simplifies the design-to-print process, these features make 3D printing more accessible to newcomers and more efficient for seasoned pros. Moreover, many of the latest printers feature enhanced connectivity options, such as Wi-Fi and cloud printing, allowing for seamless integration into your existing workflow.

Eco-Friendly and Cost-Effective

Environmental considerations and cost efficiency are increasingly important in the 3D printing industry. Newer models are designed to be more energy-efficient and are compatible with a wider range of eco-friendly materials. Additionally, advancements in technology have reduced the cost of high-quality prints, making 3D printing more affordable for personal and professional use. Upgrading to a newer model can also mean lower maintenance costs and less material waste, which translates to long-term savings and a smaller environmental footprint.

Expanding Material Compatibility

The ability to work with a broader array of materials opens up new possibilities for 3D printing projects. Recent models support everything from flexible and composite materials to advanced polymers and biocompatible resins, catering to industries as diverse as fashion, medicine, and aerospace. Upgrading your printer can expand your creative and professional horizons by enabling you to experiment with new materials and applications.

Keeping Competitive

For businesses, staying competitive often means keeping up with technological advances. An upgraded 3D printer can provide the edge needed to produce faster, innovate more, and meet client demands with unparalleled quality. In educational settings, providing students access to the latest technology prepares them for future careers and sparks innovation.

Upgrading your 3D printer in 2024 is not just about keeping up with technology; it’s about embracing the future of manufacturing, design, and art. With each advancement, 3D printing becomes more integral to various fields, making an upgrade an essential step for anyone committed to excelling in their craft.

Top 5 3D Printers of 2024

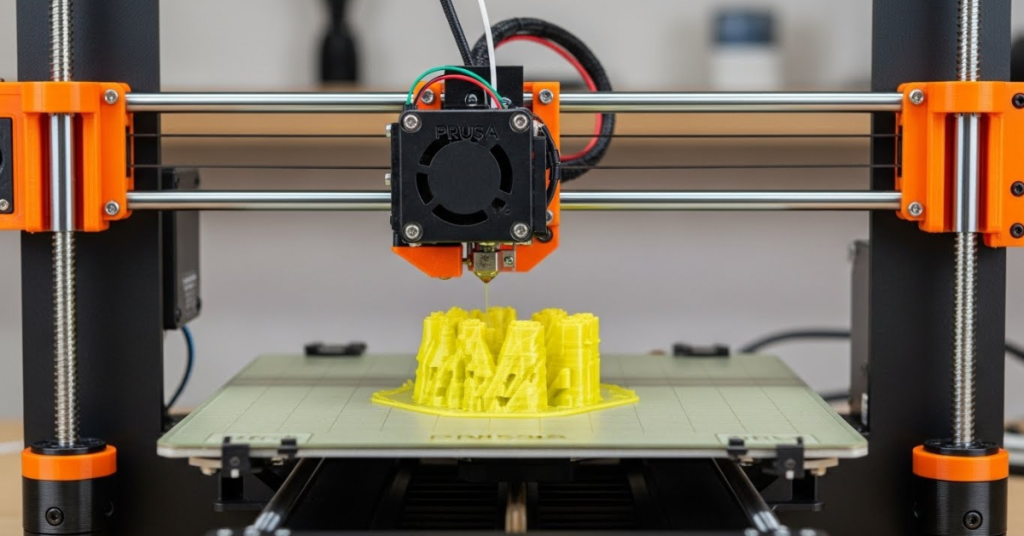

- Prusa i3 MK3S+

Reliability and Community Support

The Prusa i3 MK3S+ continues to be a beacon of reliability in the 3D printing world. Built on the legacy of the renowned Prusa i3 series, the MK3S+ is the culmination of continuous improvements and user feedback, resulting in one of the most dependable printers on the market today. Its strong community support not only provides a wealth of shared knowledge but also frequent updates that enhance the printer’s capabilities and user experience.

Innovative Features

- Automatic Bed Leveling: The MK3S+ features an upgraded bed leveling system that uses multiple points across the bed to ensure a perfectly level print surface, which is critical for achieving high-quality prints.

- Filament Sensor: An improved filament sensor detects the presence and movement of filament, helping to prevent printing errors due to jams or runouts, which can be a common headache in printing projects.

- Power Panic: This feature saves your print progress in the event of a power outage. Once power is restored, printing can resume from the exact point it stopped, reducing material waste and frustration.

Performance and Quality

With a build volume of 250 x 210 x 210 mm, the MK3S+ offers ample space for most projects while maintaining a compact footprint suitable for desktop use. The printer operates with remarkable precision, thanks to its rigid frame and precise stepper motors. The layer resolution can be as fine as 0.05 mm, allowing for incredibly detailed prints that are both structurally sound and aesthetically pleasing.

Materials and Applications

The Prusa i3 MK3S+ is not limited to standard PLA and ABS; it can handle a variety of materials, including PETG, TPU, and composites infused with carbon fiber. This versatility makes it an ideal choice for hobbyists who experiment with different materials, as well as for professionals who require specific properties in their prototypes or finished products.

User Experience

“It’s like having a reliable partner in every project,” shares a seasoned designer. “The MK3S+ handles complex designs with ease, and its consistent performance lets me focus more on creativity and less on machine tweaking.”

Why It’s a Top Pick

The Prusa i3 MK3S+ stands out for its exceptional reliability, ease of use, and superb print quality. It is particularly well-suited for educational environments, makerspaces, and anyone serious about diving into 3D printing without constant hardware issues. Its open-source nature and the robust community surrounding Prusa Research further enhance its appeal, offering endless possibilities for upgrades and customization.

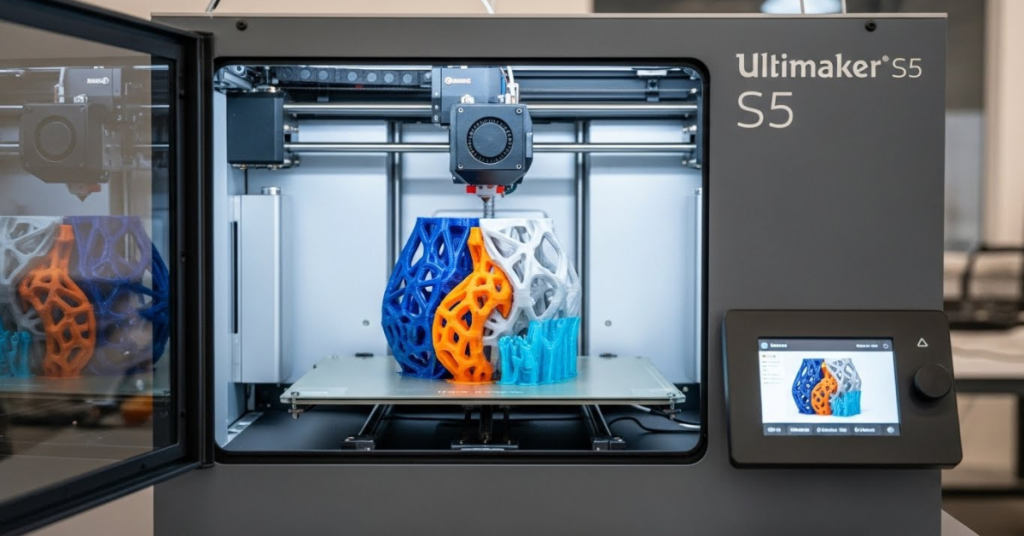

- Ultimaker S5

High-Performance and Scalability

The Ultimaker S5 is a powerhouse in professional 3D printing, designed to meet the demands of large-scale projects and high-detail applications. Known for its robust construction and reliability, the S5 is engineered to deliver consistently outstanding results over extended periods, making it a favorite among professionals in engineering, product design, and manufacturing sectors.

Innovative Features

- Dual Extrusion Capability: The S5 features advanced dual extrusion that allows for printing with two different materials simultaneously. This is particularly useful for creating complex parts with support structures or parts that require multiple materials.

- Enhanced Bed Leveling: An upgraded active bed leveling system ensures a perfect first layer, a critical factor for achieving flawless prints. The heated glass build plate further enhances adhesion, reducing warping and ensuring smooth, flat surfaces.

- Large Build Volume: With a spacious build volume of 330 x 240 x 300 mm, the Ultimaker S5 is well-suited for printing large objects or multiple parts in one go, optimizing workflow and productivity.

Performance and Quality

Precision is at the heart of the Ultimaker S5’s design. It offers layer resolutions from 20 microns, facilitating the production of parts with incredibly fine details. The printer operates with a precision that ensures dimensional accuracy and repeatability, crucial for professional applications where tolerances are tight.

Materials and Applications

The S5’s open filament system allows users to choose from a wide range of materials, including Ultimaker’s own range of filaments and third-party options. This flexibility is enhanced by the printer’s ability to handle everything from standard PLA to advanced technical materials like composites, nylons, and TPU, catering to specific industrial needs.

User Experience

“Ultimaker S5 is our go-to printer for prototyping. Its reliability and the quality of prints mean less time tinkering and more time innovating,” explains a product development manager. “The ease of use and the support from Ultimaker’s extensive online community have made integration into our workflow seamless.”

Why It’s a Top Pick

The Ultimaker S5’s combination of high performance, large build volume, and versatility makes it an excellent choice for businesses looking to scale their production capabilities or for educational institutions that demand reliability and precision for teaching and research purposes. Its comprehensive monitoring features, including an in-built camera for remote print monitoring, provide further convenience and control, making complex projects more manageable and efficient.

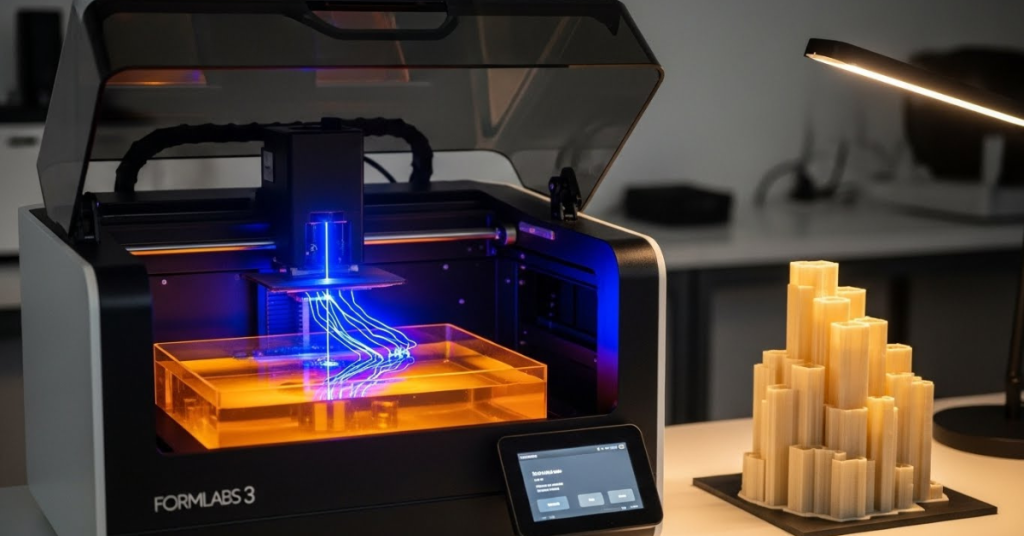

- Formlabs Form 3

Resin Printing Excellence

The Formlabs Form 3 is a leader in the resin printer market, renowned for its exceptional print quality and precision. Leveraging advanced Low Force Stereolithography (LFS) technology, the Form 3 offers a revolutionary approach to 3D printing by significantly reducing the forces of the print process. This technology not only enhances the detail and surface finish of prints but also extends the life of the printer components, ensuring reliable operation over time.

Innovative Features

- Low Force Stereolithography (LFS) Technology: This cutting-edge technology uses a flexible tank and linear illumination to deliver groundbreaking print quality with incredible detail and smooth surfaces.

- Automated Resin System: The Form 3 includes an automated cartridge system that fills the resin tank as needed, reducing manual intervention and allowing for longer, unattended print jobs.

- Advanced Optical System: The printer’s optical system maintains a precise, dense laser spot to ensure consistent, accurate prints across the entire build platform.

Performance and Quality

The Form 3 is optimized for fine detail printing, making it ideal for applications that require intricate textures and delicate features, such as jewelry, dental, and prototyping for consumer electronics. The printer operates with a laser spot size of 85 microns, providing the ability to capture minute details that are often challenging for other 3D printing technologies.

Materials and Applications

Formlabs has developed a wide range of proprietary resins for the Form 3, each formulated for specific applications. These include standard resins for general prototyping, engineering resins for functional parts, and specialty resins for biocompatible applications. The versatility in materials makes the Form 3 highly adaptable to various sectors, including healthcare, education, and art.

User Experience

“Form 3 has transformed our production of customized dental appliances. The precision it offers means our products not only fit better but are also stronger and more aesthetic,” shares a dental technician.

Why It’s a Top Pick

The Formlabs Form 3 excels where precision and fine detail are paramount. Its innovative LFS technology sets it apart in the resin printing market, offering unmatched print quality and surface finish. For professionals in sectors like healthcare, jewelry, and industrial design, the Form 3 provides the capability to produce with the exactness and quality expected in commercial-grade products. Its ease of use and reliability make it a valuable tool in any setting where detail, precision, and aesthetic matter.

- Creality Ender 3 V2

Budget-Friendly Innovation

The Creality Ender 3 V2 stands as an exemplary model of how affordability does not have to compromise quality. This printer has quickly become a favorite among hobbyists and beginners due to its excellent value proposition. With significant upgrades over its predecessor, the Ender 3 V2 combines user-friendly features with a robust design, making it an ideal entry point for those new to 3D printing or operating on a tighter budget.

Innovative Features

- Silent Motherboard: One of the standout upgrades is the inclusion of a new, ultra-quiet stepper motor driver. This feature significantly reduces noise levels, making the Ender 3 V2 ideal for home use.

- Improved Bed Leveling: The Ender 3 V2 features a newly designed rotary knob under the print bed, making it easier than ever to finely adjust the bed level without requiring additional tools.

- Glass Bed: The addition of a carborundum glass platform improves bed adhesion and results in a smoother finish on the bottom of prints. It also heats up faster and distributes heat more evenly.

Performance and Quality

Despite its status as a budget printer, the Ender 3 V2 does not skimp on performance. It offers a respectable print volume of 220 x 220 x 250 mm and supports a variety of filaments, including PLA, ABS, and TPU. The printer maintains an impressive level of precision for its price range, with the ability to print layers as fine as 100 microns.

Materials and Applications

The Ender 3 V2’s open-source nature and wide material compatibility make it highly versatile. It is popular among hobbyists for creating everything from toys and household items to more functional and mechanical parts. Its ease of use also makes it a fantastic educational tool, providing students and beginners a hands-on experience with 3D printing technology without a steep learning curve.

User Experience

“The Ender 3 V2 was my first 3D printer, and it was incredibly straightforward to set up and start printing. It’s amazing what kind of quality you can get from such an affordable machine,” shares a 3D printing enthusiast.

Why It’s a Top Pick

For those looking to dive into 3D printing without making a hefty investment, the Creality Ender 3 V2 offers the best of both worlds—affordability and quality. Its enhancements in usability and print quality make it not just accessible but also a joy to use. Whether you are a beginner looking to explore 3D printing or an experienced maker on a budget, the Ender 3 V2 delivers solid performance at a price point that is hard to beat.

- MakerBot Replicator+

Versatile and User-Friendly

The MakerBot Replicator+ is a testament to MakerBot’s commitment to delivering reliable and user-friendly 3D printing solutions. An evolution of the trusted Replicator line, this model enhances the user experience with improved hardware and software features. It is particularly favored in educational settings and small businesses where versatility and ease of use are paramount.

Innovative Features

- Flex Build Plate: The Replicator+ features a flex build plate with a grip surface, which significantly improves model adhesion during printing and reduces warping. The flexible plate also allows for easier and quicker model removal once printing is complete.

- Smart Extruder+: This updated extruder increases reliability and reduces clogging. It’s easily swappable, minimizing downtime and facilitating maintenance.

- Onboard Camera: A built-in camera allows for remote monitoring of print jobs through the MakerBot Mobile app, making it easier to manage prints from anywhere.

Performance and Quality

The MakerBot Replicator+ boasts a 25% larger build volume than its predecessor, providing more flexibility for larger prints or batch production of smaller parts. It delivers consistent print quality, with a resolution capability of down to 100 microns. The printer is optimized for PLA filament, ensuring non-toxic, office-safe printing without the need for a heated build plate.

Materials and Applications

MakerBot offers a range of PLA composite filaments, including ones embedded with materials like bronze, limestone, and maple wood, providing a variety of textures and aesthetic finishes. The Replicator+ is adept at producing educational models, prototypes, and architectural designs, making it a versatile tool for classrooms, labs, and design studios.

User Experience

“We use the MakerBot Replicator+ in our design lab at school. It’s reliable, easy to use, and the students love watching their creations come to life,” explains a high school technology teacher. “The ability to monitor the prints remotely is incredibly beneficial, allowing us to maintain flexibility in our lesson planning.”

Why It’s a Top Pick

The MakerBot Replicator+ stands out for its robust construction, reliability, and user-friendly features, making it ideal for educational and professional settings. Its enhanced print quality, combined with the convenience of remote monitoring and the ease of maintenance with the Smart Extruder+, provides a seamless 3D printing experience. For educators and professionals who require a dependable, safe, and efficient 3D printer, the Replicator+ offers an excellent balance of performance and practicality.

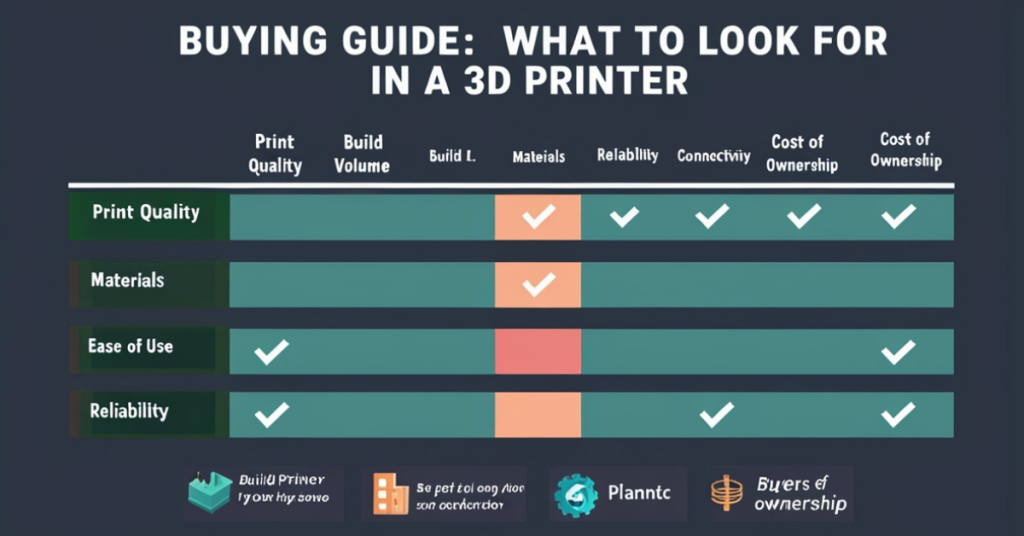

Buying Guide: What to Look for in a 3D Printer?

Choosing the right 3D printer involves more than just comparing prices and print volumes. Whether you are a first-time buyer or looking to upgrade your current machine, understanding the different aspects that contribute to a printer’s performance and suitability for specific tasks is crucial. Here are the key features and considerations to keep in mind:

Print Quality and Resolution

- Layer Resolution: This refers to the thickness of each layer that the printer can produce, typically measured in microns. Lower numbers mean finer layers that are less visible to the naked eye, resulting in smoother and more detailed prints.

- Print Speed: While faster print speeds can save time, they often come at the cost of print quality. Find a balance that does not compromise the detail and quality of your projects.

Build Volume

- Size Matters: The build volume determines the maximum size of objects you can print. Consider what you plan to print and ensure the printer can accommodate those dimensions.

Material Compatibility

- Filament Types: Some printers are limited to specific types of materials. Common materials include PLA, ABS, PETG, and TPU, but some printers also handle more advanced materials like composites or water-soluble supports.

- Enclosed Chamber: For materials that warp easily, such as ABS, an enclosed chamber helps maintain a consistent temperature to reduce warping.

Ease of Use

- User Interface: A user-friendly interface with a clear display can make all the difference in your printing experience. Touchscreens provide an intuitive way to control your printer.

- Leveling: Auto-bed leveling technology saves time and hassle by automatically calibrating the print bed to ensure a flat surface for printing.

Reliability and Support

- Durability: Check for reviews and user feedback on the printer’s reliability over time. A sturdy frame and high-quality components can reduce vibrations and improve print quality.

- Customer Support and Community: A responsive customer service team and an active community forum can be invaluable for troubleshooting and tips, especially for those new to 3D printing.

Connectivity and Software

- Connectivity Options: Options like USB, Wi-Fi, and Ethernet can affect how you send files to your printer. Some models also offer remote monitoring and control through apps.

- Software Compatibility: Ensure that the printer is compatible with the software you plan to use for designing and slicing your models. Some printers work with proprietary software, while others are compatible with a variety of open-source options.

Maintenance and Upgrades

- Maintenance Needs: Regular maintenance is crucial for keeping your 3D printer in good working order. Check what routine maintenance is recommended and how often it needs to be performed.

- Upgradability: Consider whether the printer can be upgraded with new components or software updates. This can extend its lifespan and improve functionality over time.

Cost of Ownership

- Initial Investment vs. Operating Cost: Beyond the purchase price, consider the ongoing costs of materials, replacement parts, and energy consumption. Some printers offer a lower upfront cost but may have higher long-term operating expenses.

By carefully evaluating these factors, you can choose a 3D printer that not only fits your budget but also meets your specific needs and expectations, ensuring that you make a sound investment in your creative endeavors.

Conclusion

Choosing the best 3D printer for your projects in 2024 is about much more than picking the most technologically advanced or the most expensive model. It’s about finding a machine that aligns perfectly with your specific needs, whether those involve high-detail resin printing for jewelry design, robust and reliable large-scale printing for educational purposes, or a budget-friendly model for hobbyist ventures.

The 3D printers we’ve highlighted in this guide—ranging from the precision of the Formlabs Form 3 to the versatility of the MakerBot Replicator+—demonstrate the diversity and sophistication available in today’s market. Each model brings something unique to the table, and your choice should be guided by a combination of performance specifications, material compatibility, and user-friendly features that suit your workflow.

Embrace the Future of 3D Printing

As 3D printing technology continues to evolve, staying informed about the latest advancements and how they can benefit your specific applications is crucial. By choosing a printer that not only meets today’s standards but is also capable of adapting to tomorrow’s innovations, you can ensure a long-term investment that grows with your skills and ambitions.

A Call to Action: Engage with the Community

Don’t hesitate to reach out to user communities and forums for advice. The experiences of others can provide invaluable insights into the reliability and performance of different printers over time. Moreover, participating in these communities can also offer ongoing support and inspiration for your projects.

Your Partner in Creativity

Remember, a good 3D printer doesn’t just perform tasks—it enhances your creative process, reduces your workload through reliable performance, and opens up new possibilities for innovation and design. Choose wisely, and let your chosen 3D printer be a partner in your creative journey, helping to bring your visions to life with precision and ease.

By carefully considering the insights and recommendations shared in this guide, you are well on your way to selecting a 3D printer that will not only meet but exceed your expectations, ensuring that your projects achieve the quality and impact you desire.

FAQs

- What should I prioritize when choosing a 3D printer?

Consider print quality, printer reliability, and specific feature needs. - How do I maintain a 3D printer?

Regular cleaning and calibration are essential for optimal performance. - Can these printers use third-party materials?

Some printers are open to third-party materials, but check manufacturer guidelines. - What is the lifespan of a 3D printer?

With proper maintenance, many can last for several years. - Where can I buy these 3D printers?

Check official websites or authorized retailers for purchase options.