Multicolor/Multi-material Printing: Unlocking Creativity and Functionality

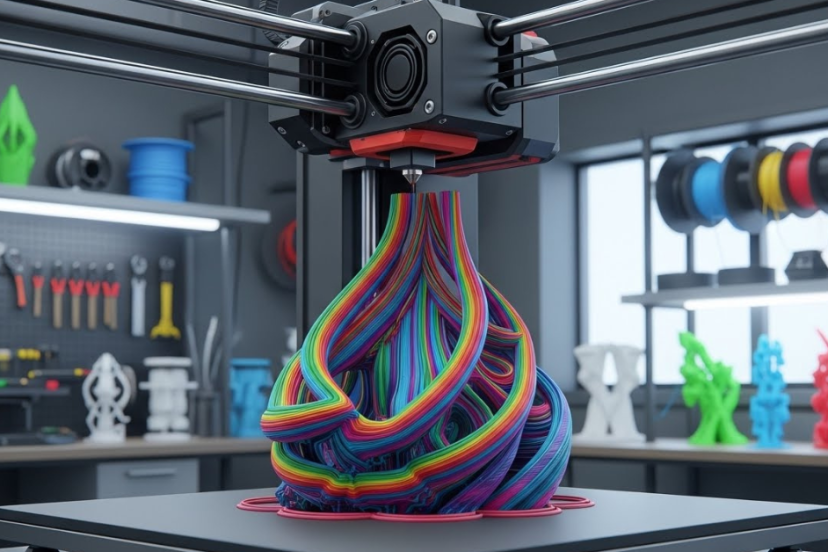

Welcome to the revolutionary world of 3D printed multicolor, where imagination meets reality, and the possibilities stretch as far as the eye can see. In the ever-evolving landscape of 3D printing, the introduction of multicolor and multi-material capabilities has marked a significant milestone, transforming the way we conceive and create objects. This technology is not just about splashing a spectrum of colors onto your projects; it’s about bringing a new dimension of creativity and functionality to life. Whether it’s crafting stunning models that stand out with lifelike detail or engineering complex components with diverse materials in a single print, multicolor 3D printing is at the forefront of innovation.

But what exactly propels this technology beyond the traditional boundaries of 3D printing? At its heart, multicolor and multi-material printing embodies the fusion of artistic vision with practical application. By enabling the simultaneous use of multiple filaments or resins, these printers allow creators to design with an unprecedented range of colors and materials. From vibrant hues that mimic the real world to distinct material properties within a single object, the results are as functional as they are beautiful.

Imagine the impact on prototyping, where a single print can now include transparent sections for visualization, rubber-like components for functional testing, and rigid parts for structural integrity—all rendered in the exact colors of the final product. Or consider the realm of custom goods, where personalization reaches new heights with products designed to match the unique preferences and needs of individuals.

In this comprehensive guide, we will explore the depths of 3D printed multicolor technology: its principles, its applications, and, most importantly, how it unlocks a world where your creative visions and practical needs converge in vibrant harmony. Join us as we delve into the colorful and multi-dimensional future of 3D printing, a future where every print tells a story, every layer adds value, and every color brings an idea closer to reality.

The Basics of 3D Printing

The journey into the fascinating world of 3D printing begins with understanding its core principles. At its simplest, 3D printing is a form of additive manufacturing that creates objects from digital models by layering material, layer by layer, until a physical object takes shape. This method stands in contrast to traditional subtractive manufacturing techniques, which involve cutting away material from a solid block to form an object. The beauty of 3D printing lies in its ability to produce complex and intricate designs that would be challenging, if not impossible, to achieve with conventional methods.

Technologies and Materials

Several technologies underpin 3D printing, each suited to different applications and materials. The most common among these is Fused Deposition Modeling (FDM), where a filament of thermoplastic material is heated and extruded through a nozzle, hardening upon contact to form layers. Stereolithography (SLA) uses a laser to cure liquid resin into solid plastic in a precise, layer-by-layer fashion. Selective Laser Sintering (SLS), on the other hand, fuses powder particles together using a laser, allowing for the printing of functional parts with complex geometries.

Materials play a crucial role in 3D printing, with options ranging from plastics like PLA and ABS to more specialized materials like TPU (flexible), PETG (durable and food-safe), and a variety of resins for SLA printers, offering different properties such as flexibility, durability, and transparency. Metals can also be 3D printed using more advanced technologies like Direct Metal Laser Sintering (DMLS), opening up applications in aerospace, automotive, and medical industries.

Designing for 3D Printing

Designing for 3D printing requires a blend of creativity and technical skill. It starts with a 3D model, created in computer-aided design (CAD) software, which is then sliced into thin layers by specialized software. This slicing software converts the model into a series of instructions (G-code) for the 3D printer, detailing how each layer should be constructed. Design considerations include the orientation of the part, the need for support structures to prevent overhangs from collapsing during printing, and the optimization of the model to minimize material use and printing time.

From Monochrome to Multicolor

Initially, 3D printing was predominantly monochromatic, limiting the visual and functional scope of printed objects. The transition to multicolor and multi-material printing has dramatically expanded the creative and practical applications of 3D printing. By incorporating multiple colors and materials into a single print job, users can create objects with enhanced aesthetic appeal and complex functionalities, including varied textures, material properties, and mechanical components, all seamlessly integrated into one print.

Understanding these basics sets the stage for appreciating the transformative potential of multicolor and multi-material 3D printing. As we delve deeper into this technology, it becomes clear that we are standing at the brink of a new era in manufacturing, where the only limit is our imagination.

The Technology Behind Multicolor Printing

The allure of multicolor 3D printing is not just in its visual appeal but in the intricate technology that enables these vibrant creations. Moving beyond single-color prints, multicolor printing introduces a complexity that combines precision, material science, and software ingenuity to bring vivid colors and diverse material properties into a single object. Let’s explore the key technologies and innovations driving this colorful revolution.

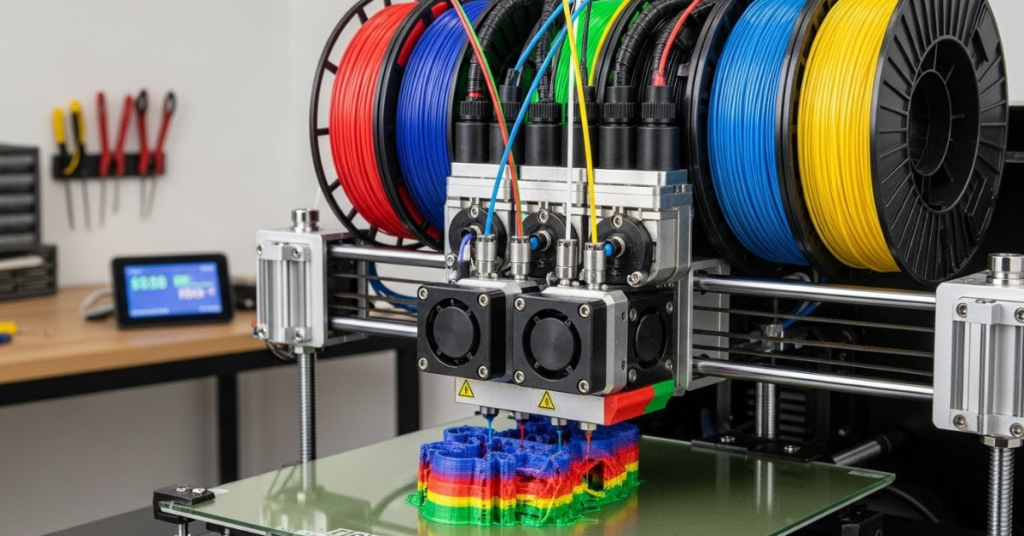

Dual or Multi-Extruder Systems

One of the most straightforward approaches to multicolor 3D printing involves printers equipped with dual or multiple extruders. Each extruder can feed a different color or type of filament into the print, allowing for the creation of objects with distinct colors and materials. The challenge here lies in precisely controlling each extruder and synchronizing the material flow to achieve clean transitions and sharp definitions between colors and materials.

Color Blending Technologies

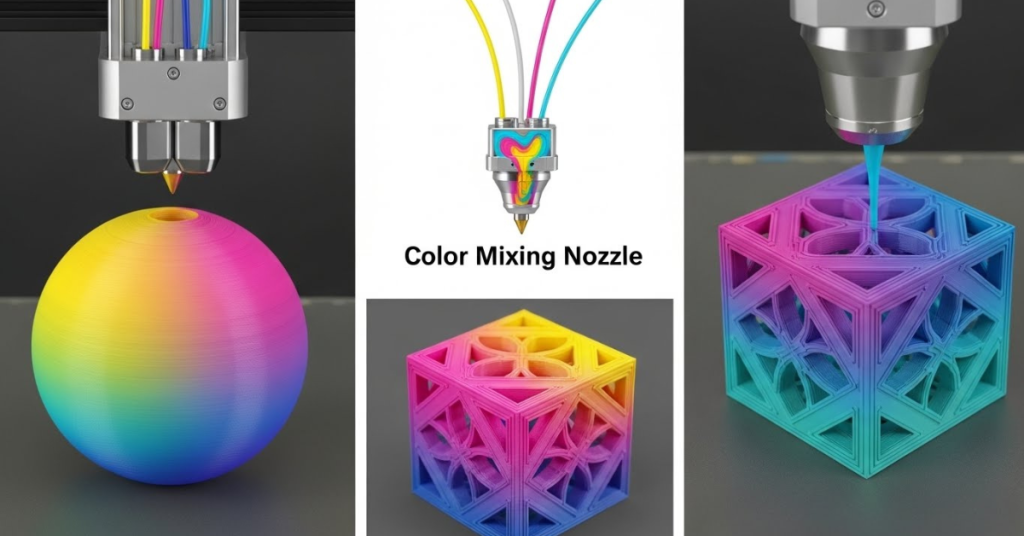

More advanced than simple dual extrusion, some printers feature color blending technologies that can mix primary colors of filament before extrusion. This method enables the production of a wide spectrum of colors from just a few base filaments. The printhead can mix these colors in controlled proportions, allowing for gradient effects and a vast range of hues within a single layer or throughout an object.

Inkjet-Based 3D Printing

Adopting a technique reminiscent of traditional 2D inkjet printing, certain high-end 3D printers can deposit a binding agent onto a powder bed, with the ability to add full-color dyes during the process. This method is particularly effective for creating full-color prototypes and models with intricate details and a wide range of colors. The resulting objects often require post-processing to improve durability but can achieve unparalleled color accuracy and detail.

Material Jetting

Material jetting works similarly to inkjet document printing but with 3D printing materials. It sprays droplets of a photopolymer that are instantly cured by ultraviolet light. This process allows for the printing of parts with multiple materials and colors in a single object. Material jetting is known for its high precision and smooth surface finish, making it ideal for detailed prototypes and models that require exact color matches.

Limitations and Innovations

Despite these advancements, multicolor 3D printing faces challenges such as color fidelity, material compatibility, and the complexity of managing multiple materials. However, ongoing innovations continue to push the boundaries. For instance, research into new filament materials and colorants, improved slicing software that can better manage color transitions and material properties, and advancements in printer hardware all contribute to the maturation of this technology.

Looking Ahead

The technology behind multicolor 3D printing is evolving rapidly, with each breakthrough bringing us closer to seamless integration of color and material in additive manufacturing. As these technologies become more accessible and refined, we can anticipate a future where multicolor and multi-material 3D printing becomes the standard, unlocking new levels of creativity and functionality.

Exploring the technology behind multicolor printing reveals a field ripe with innovation and potential. By understanding these technologies, we gain insight into the capabilities and future direction of multicolor 3D printing, opening up endless possibilities for creators, designers, and innovators worldwide.

Why Multicolor Matters

In the world of additive manufacturing, the transition to multicolor printing is not just a leap in technology but a stride towards new horizons of creativity and practical application. Here’s why the ability to print in multiple colors and materials is revolutionizing the field.

Enhanced Aesthetic Appeal

The most immediate impact of multicolor 3D printing is its ability to produce objects that are visually striking and more representative of their final intended look. This capability is invaluable in sectors like fashion, home decor, and art, where the visual presentation is as important as the object’s functionality. Multicolor printing enables designers to experiment with color schemes and textures, making each creation not just a piece but a spectacle.

Realistic Prototypes and Models

For industries that rely on prototypes and models to visualize products before mass production, multicolor printing is a game-changer. It allows for the creation of prototypes that closely resemble the final product in terms of color, material properties, and texture. This realism can enhance communication with stakeholders, reduce the time and cost associated with iterative design processes, and improve the final product’s market fit.

Complex Educational Tools

In educational settings, multicolor 3D printing can create detailed anatomical models, complex geometric shapes, and historical artifacts, enhancing learning through tactile and visual engagement. These models can illustrate concepts in a way that 2D images or monochromatic models cannot, making education more interactive and impactful.

Customization and Personalization

The ability to incorporate multiple colors and materials into a single print opens up unparalleled opportunities for customization. Whether it’s personalized merchandise, bespoke jewelry, or tailor-made medical devices, multicolor printing can cater to the unique preferences or needs of individuals. This level of personalization is becoming increasingly important in a market where differentiation and individual expression are highly valued.

Functional and Mechanical Properties

Beyond aesthetics, the integration of multiple materials into a single print allows for objects with varied mechanical and functional properties. For instance, a single print could include both rigid and flexible parts, transparent and opaque sections, or conductive and insulative elements. This capability is crucial for functional prototypes, wearable technology, and customized tools or components that must meet specific performance criteria.

Sustainability and Efficiency

Multicolor and multi-material printing can also contribute to sustainability efforts. By reducing the need for painting, assembly, and material waste, this technology supports more efficient production processes. Additionally, the ability to print objects with the exact color and material specifications in a single process reduces the carbon footprint associated with manufacturing and transporting multiple parts.

The Future of Creativity and Innovation

As we continue to explore the boundaries of what’s possible with 3D printing, multicolor and multi-material capabilities stand out as key drivers of innovation. They enable not just the creation of objects that are more beautiful, realistic, and functional, but also the realization of ideas that were previously unthinkable. In this light, multicolor matters not just as a technological achievement, but as a catalyst for creativity, learning, and personal expression in the digital age.

The significance of multicolor 3D printing lies in its ability to bridge the gap between imagination and reality, bringing to life creations that are as diverse and dynamic as the world around us.

Multicolor Printing Techniques

The ability to print in multiple colors and materials has transformed 3D printing into a more versatile and creative endeavor. Several techniques have been developed to achieve this, each with its unique approach and application. Understanding these techniques is crucial for anyone looking to explore the full potential of multicolor 3D printing.

Fused Deposition Modeling (FDM) with Multiple Extruders

One of the most common methods for achieving multicolor prints is through Fused Deposition Modeling (FDM) printers equipped with multiple extruders. Each extruder can feed a different color of filament into the print, allowing for the creation of designs that feature distinct colors in specified areas. Some printers come with dual extruders, while others may have four or more, greatly expanding the palette of colors available in a single print. The challenge with this method lies in ensuring clean transitions between colors and managing the oozing of inactive extruders, which can mar the print’s surface.

Color Mixing Nozzle Technology

Advanced FDM printers incorporate color mixing nozzle technology, which allows for the blending of two or more filament colors directly in the nozzle. This technology can create a gradient effect or smoothly transition between colors within the same layer. Color mixing nozzles offer a broader color spectrum with fewer physical extruders, providing more nuanced control over the color output and enabling a wider range of color effects within prints.

Material Jetting

Material jetting operates similarly to inkjet printing but in three dimensions. It deposits droplets of a photosensitive material onto the build platform, which are then cured by UV light. This process is precise enough to allow for the printing of multiple materials in the same object, including different colors. The result is prints with a high level of detail and smooth surface finishes, suitable for prototypes and models that require precise color matching.

Binder Jetting with Full-Color Capability

Binder jetting technology involves spreading a layer of powder (such as gypsum-based or metal powder) and selectively jetting a binding agent that is mixed with dyes for color. This method can produce full-color prints with a wide range of hues and gradients, making it ideal for detailed figurines, architectural models, and other applications where color detail is critical. The finished objects may require post-processing to enhance their strength and durability.

Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF) with Color

While traditionally used for monochrome prints, Selective Laser Sintering (SLS) and HP’s Multi Jet Fusion (MJF) technologies have been adapted to incorporate color. By using colored powders or treating the parts during the printing process with colored dyes, these techniques can create colored objects. However, the color range and saturation levels are generally more limited compared to other multicolor techniques.

Limitations and Opportunities

Each multicolor printing technique comes with its own set of challenges, including color accuracy, material properties, and the complexity of the printing process. However, ongoing innovations in printer design, material science, and software are continually pushing the boundaries of what can be achieved. As these technologies evolve, we can expect to see even more sophisticated multicolor and multi-material printing capabilities, opening up new avenues for creativity, functionality, and personalized production.

By leveraging these diverse multicolor printing techniques, creators and manufacturers can bring to life objects that are not only visually captivating but also functionally dynamic, merging the realms of art, design, and engineering in exciting new ways.

The Fastest 3D Printers on the Market

In the rapidly evolving world of 3D printing, speed is a crucial factor for businesses and hobbyists alike. However, achieving quick print times without sacrificing quality, especially in multicolor printing, requires advanced technology. Below are some of the fastest and most reliable 3D printers available that can handle multicolor projects.

Stratasys J750 and J850

The Stratasys J750 and its successor, the J850, are renowned for their exceptional full-color printing capabilities. They utilize PolyJet technology, which jets layers of curable liquid photopolymer onto a build tray. These printers can produce parts with a vast array of colors, gradients, and material properties all in a single print, making them ideal for prototypes, tooling, and final product applications. Their speed, combined with the ability to print with multiple materials simultaneously, sets them apart in the professional 3D printing market.

3D Systems ProJet CJP 660Pro

The ProJet CJP 660Pro by 3D Systems specializes in full-color sandstone printing and is known for its fast print speeds in the realm of color 3D printing. Utilizing ColorJet Printing (CJP) technology, it distributes a fine layer of powder and then jets a binding agent in specific areas, which is mixed with color to produce vibrant prints. This printer is particularly popular for creating realistic models and prototypes that require a wide color palette.

HP Jet Fusion 580 Color

HP’s Jet Fusion 580 Color is a noteworthy mention for its speed and ability to produce functional parts in vibrant colors. Leveraging HP’s Multi Jet Fusion (MJF) technology, it offers a rapid layering process that can produce parts up to ten times faster than SLS machines, according to HP. This printer is designed for small to medium-sized product development teams and businesses that need to prototype or produce parts with fine detail and full color.

Ultimaker S3 and S5

While not exclusively multicolor printers, the Ultimaker S3 and S5 models deserve mention for their versatility, speed, and reliability. With the addition of a dual extrusion system, these printers can handle two colors or materials in a single print. Known for their ease of use and high-quality prints, they are suitable for a wide range of applications, from educational purposes to professional prototyping and manufacturing. The Ultimaker printers are particularly praised for their efficient print times and excellent material compatibility.

Prusa i3 MK3S+

The Prusa i3 MK3S+ is a highly versatile and reliable 3D printer that, while primarily designed for single-color prints, can be adapted for multicolor printing with the addition of the Multi-Material Upgrade (MMU2S). This upgrade allows it to handle up to five different materials in one print. While the setup and use of the MMU2S may offer a slight learning curve, the base printer itself is renowned for its print quality, reliability, and user-friendly features, making it a great choice for beginners looking to explore multicolor printing as they advance their skills.

Creality Ender 3 V2

The Creality Ender 3 V2 is an upgrade from one of the most popular budget-friendly 3D printers on the market. While it is a single-extruder printer, it can achieve multicolor prints through filament swapping either manually or with the addition of inexpensive modifications and accessories. Its affordability, combined with a relatively straightforward assembly and tuning process, makes it an excellent entry point for beginners interested in exploring the basics of 3D printing, including initial forays into multicolor projects.

Evaluating Speed in 3D Printing

When considering the speed of a 3D printer, it’s essential to look beyond just the raw print speed. Factors such as the time required for setup, post-processing, and the printer’s ability to handle complex multicolor or multi-material jobs efficiently are crucial. The fastest printers in the market are those that offer a combination of quick print times and the flexibility to produce detailed, high-quality multicolor prints without extensive manual intervention.

These printers represent the pinnacle of what’s currently achievable in rapid, multicolor 3D printing. As technology advances, we can expect to see even faster printers that do not compromise on quality or color fidelity, further revolutionizing the fields of prototyping, manufacturing, and creative design.

How to Choose the Right Printer

Determine Your Primary Use

Before diving into the specifications of different printers, clarify what you primarily need the printer for. Are you creating detailed prototypes, custom artwork, educational models, or functional parts? Your primary use will guide your choice, as different printers excel in various aspects, such as color accuracy, material compatibility, and print speed.

Multicolor Capabilities

Since multicolor printing is your focus, evaluate how well different printers handle multiple colors or materials. Consider the technology they use (e.g., dual extruders, color mixing nozzles, or material jetting) and the range of colors they can produce. Some printers offer extensive color palettes and gradient capabilities, essential for detailed and realistic prototypes.

Material Compatibility

Your projects might require printing with different materials, from standard plastics like PLA and ABS to more specialized ones like TPU, PETG, or even resin. Check if the printer supports the materials you plan to use and whether it can handle printing with multiple materials simultaneously, if that’s a requirement for your work.

Print Speed and Quality

While speed is important, it shouldn’t come at the expense of print quality. Assess the printer’s ability to produce high-quality prints at a pace that meets your needs. Remember, multicolor and multi-material printing can be more time-consuming than single-material prints, so find a balance that works for you.

Ease of Use

Consider the printer’s user interface, software compatibility, and overall ease of use. Printers with intuitive interfaces, robust slicing software, and reliable support can significantly enhance your printing experience, especially when dealing with the complexities of multicolor printing.

Build Volume

The size of the objects you plan to print will dictate the required build volume. Ensure the printer has a large enough build area to accommodate your projects without the need for splitting and assembling parts post-printing.

Resolution and Layer Height

For projects that demand fine detail, look into the printer’s resolution and minimum layer height. These specifications will tell you how detailed and smooth the surface of your prints can be, which is particularly important for intricate designs and high-quality prototypes.

Cost and Budget Considerations

Multicolor printers can vary widely in price, from affordable desktop models to high-end professional machines. Consider the total cost of ownership, including the initial purchase price, the cost of materials, and any ongoing maintenance expenses. Align your choice with your budget and the value the printer will bring to your projects.

Community and Support

A strong user community and reliable manufacturer support can be invaluable, especially when you’re navigating the complexities of multicolor printing. Look for printers with active forums, user groups, and responsive customer service to help troubleshoot issues and improve your skills.

Future-Proofing

Finally, consider how the printer fits with your future goals. Will it be able to handle more complex projects as your skills and needs evolve? Is the manufacturer known for updating and supporting their products long-term? Choosing a printer that can grow with you will ensure it remains a valuable tool in your creative or professional arsenal.

By carefully considering these factors, you can choose a 3D printer that not only meets your current needs but also supports your future projects and ambitions in multicolor 3D printing.

Preparing Your Design for Multicolor Printing

Understand Your Printer’s Capabilities

Before you start designing, it’s essential to know what your printer (or the printer you intend to use) is capable of in terms of multicolor printing. Different printers have varying methods for handling colors and materials, such as dual extruders, color mixing technologies, or material jetting. This knowledge will influence how you prepare your design.

Software Selection

The choice of software can significantly impact the ease with which you can prepare and print a multicolor design. Use 3D modeling software that allows you to assign different colors or materials to specific parts of your model. Some slicing software also offers advanced features for multicolor printing, enabling you to assign colors to different layers or sections of your print directly within the slicer.

Design with Color in Mind

When designing for multicolor printing, think about how colors will define, enhance, or differentiate parts of your model. Use colors strategically to highlight features, create contrasts, or convey information. Remember, the transition between colors can vary depending on the printing technique, so design with potential color bleed or mixing in mind.

Optimize for Material Properties

If your design incorporates multiple materials (for example, rigid and flexible parts), consider the mechanical properties and how they will affect the object’s functionality. Ensure that your design takes into account the different properties of each material, such as their strength, flexibility, and how they adhere to each other.

Simplify Color Changes

To minimize printing complexity and time, try to reduce the number of color changes or transitions. This can involve grouping elements of the same color together or planning your design so that color changes happen less frequently. However, for printers with advanced color mixing capabilities, this may be less of a concern.

Test Print Small Sections

Before committing to a full print, consider test printing a small section of your design to check how the colors appear and interact. This step can help you adjust your design or settings to achieve the desired outcome, saving time and materials in the long run.

Consider the Final Use

Think about how the object will be used or displayed. Areas subject to wear or handling might benefit from darker colors to hide marks, while display pieces can have a wider color range.

Also, consider the orientation of the object during printing, as this can affect the appearance of colors and the need for support structures, which might alter the final color or material finish.

File Preparation and Slicing

Finally, prepare your file for printing by ensuring it’s in a format compatible with your printer’s software. During the slicing process, pay attention to settings that can affect color quality, such as layer height and infill. The slicer will generate the G-code needed for printing, which instructs the printer on how to lay down each layer of material, including where and when to change colors.

By carefully preparing your design for multicolor printing, you can maximize the potential of your printer and materials, resulting in prints that are both beautiful and functional. This preparation phase is as much a part of the creative process as the initial design, offering a unique opportunity to bring your visions to life in vibrant color.

Potential Challenges and Solutions in Multicolor 3D Printing

Color Bleeding

- Challenge: Color bleeding occurs when colors mix unintentionally, leading to muddy or unclear boundaries between different colored sections of the print.

- Solution: To minimize color bleeding, optimize print settings such as temperature and retraction. Using a prime tower or ooze shield can also help by wiping and purging the nozzle between color changes.

Material Compatibility

- Challenge: Different materials may not adhere well to each other or may require significantly different print settings, complicating the process of multicolor printing with multiple materials.

- Solution: Research and select materials that are known to be compatible or have similar printing requirements. Conduct small-scale tests to determine optimal print settings for material combinations.

Complex Design Preparation

- Challenge: Preparing a design for multicolor printing can be complex, requiring detailed attention to color assignment and the division of the model into color-specific sections.

- Solution: Utilize 3D modeling and slicing software that supports multicolor printing, allowing for easier color assignment and visualization of the final print. Consider simplifying the design to reduce the number of color changes if possible.

Increased Print Time and Cost

- Challenge: Multicolor printing often takes longer and uses more material than single-color printing, leading to increased print times and higher costs.

- Solution: Efficiently plan your print jobs to minimize wasted material and unnecessary color changes. Consider the economic and time trade-offs of multicolor printing for each project to ensure it’s justified by the final outcome.

Post-Processing Requirements

- Challenge: Multicolor prints may require additional post-processing to achieve the desired finish or to remove support structures that could mar the appearance of the print.

- Solution: Design with post-processing in mind, aiming to reduce the need for supports or optimizing their placement. Explore different post-processing techniques, such as sanding, painting, or coating, to enhance the final appearance.

Software Limitations

- Challenge: Not all 3D printing software is fully equipped to handle multicolor printing efficiently, which can limit design capabilities and the final print quality.

- Solution: Seek out and invest in software solutions specifically designed for multicolor printing. Stay updated on software updates or consider third-party software that offers advanced multicolor printing features.

Calibration and Maintenance

- Challenge: Multicolor printers, especially those with multiple extruders, require careful calibration and regular maintenance to ensure accurate color placement and print quality.

- Solution: Regularly calibrate your printer according to the manufacturer’s guidelines. Perform routine maintenance checks and cleanings to keep the printer in optimal condition for multicolor printing.

Overcoming these challenges in multicolor 3D printing requires a combination of technical know-how, patience, and creativity. By anticipating potential issues and preparing with solutions in mind, you can achieve vibrant, detailed, and functional multicolor prints. This not only enhances the aesthetic appeal of your creations but also opens up new possibilities for innovation and design in 3D printing.

Case Studies in Multicolor 3D Printing

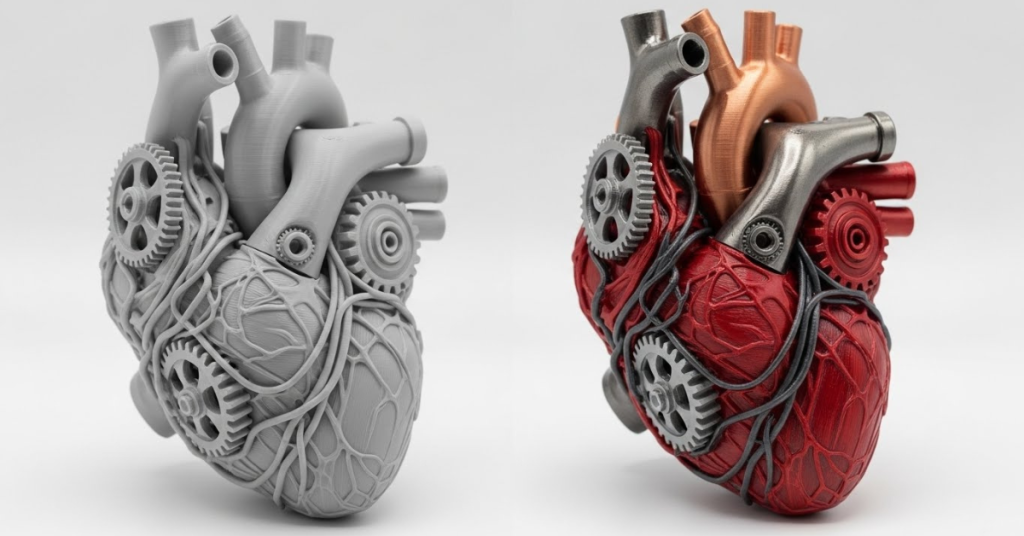

Medical Models for Surgical Planning

- Challenge: Surgeons often rely on 2D images or generic anatomical models for pre-surgical planning, which may not fully represent the complexity of individual patient cases.

- Solution: Using multicolor 3D printing, hospitals and medical institutions have started creating patient-specific models of organs, bones, or other anatomical features. These models are printed in multiple colors to differentiate between tissues, such as arteries, muscles, and bones, providing surgeons with a detailed, tactile reference for planning surgeries. A notable example is the use of 3D-printed models for complex heart surgeries, where precise understanding of the anatomy can significantly impact surgical outcomes.

Educational Tools for Enhanced Learning

- Challenge: Traditional educational aids often fail to fully engage students or accommodate different learning styles.

- Solution: Educators are turning to multicolor 3D printing to create detailed, color-coded models that illustrate complex concepts in science, geography, history, and more. For instance, multicolored geological strata models help students visualize earth science concepts, while historical artifacts reproduced in full color bring history lessons to life. These tools offer a hands-on learning experience that can enhance comprehension and retention.

Customized Consumer Products

- Challenge: Consumers increasingly seek products that reflect their personal style and preferences, a demand that mass-produced items can’t always satisfy.

- Solution: Companies are using multicolor 3D printing to offer personalized products, from custom-fit eyewear with frames in the wearer’s choice of colors to unique phone cases featuring multicolored designs. This approach allows for a high degree of customization without the need for large inventory or complex manufacturing processes, catering to the growing market for personalized products.

Innovative Art and Fashion

- Challenge: Artists and designers often face limitations in bringing their visions to life, especially when their concepts involve intricate designs or a wide palette of colors.

- Solution: Multicolor 3D printing has become a tool for artists and fashion designers to create complex, vibrant pieces that were previously impossible or prohibitively expensive to produce. For example, elaborate multicolored sculptures that combine various materials and textures, or fashion accessories that feature intricate patterns and hues, demonstrate the technology’s ability to break new ground in creative expression.

Prototyping for Product Development

- Challenge: Developing a new product often involves creating prototypes, which can be time-consuming and costly, especially when multiple iterations are needed to test different aspects of the design.

- Solution: Businesses are leveraging multicolor 3D printing to streamline the prototyping process. By producing functional prototypes that accurately represent the final product in terms of color, material properties, and design details, companies can reduce development cycles and costs. This is particularly valuable in industries like consumer electronics, where aesthetic appeal and functionality are key to market success.

These case studies illustrate the transformative impact of multicolor 3D printing across a range of applications. By enabling the creation of detailed, functional, and personalized objects, multicolor printing is not just an advancement in manufacturing technology—it’s a tool that empowers innovation, education, and artistic expression, marking a new era in how we think about and interact with the physical world.

The Future of Multicolor 3D Printing

Advanced Color Mixing Technologies

The development of sophisticated color mixing technologies will enable printers to produce an even broader spectrum of colors with higher fidelity. These advancements will likely reduce the need for multiple extruders by allowing precise control over color blending directly in the printhead. This evolution will not only enhance the aesthetic qualities of prints but also streamline the printing process.

Improved Material Compatibility

Future multicolor printers will likely support a wider range of materials, including new composites, bio-materials, and conductive inks, enabling prints with diverse functional properties. This expansion in material compatibility will open up new applications for multicolor 3D printing, from wearable electronics that integrate conductive pathways to biocompatible medical devices customized for individual patients.

Increased Print Speed and Efficiency

As technology evolves, we can expect to see significant improvements in print speed without compromising the quality of multicolor prints. Innovations in printer hardware and software, including more efficient slicer algorithms and faster curing processes, will reduce print times, making multicolor 3D printing more viable for mass production and rapid prototyping.

Seamless Integration of Multiple Materials

The integration of multiple materials within a single print job will become more seamless, allowing for the creation of objects with complex internal structures and varied material properties. This capability will be particularly impactful in fields such as robotics and prosthetics, where the combination of rigidity and flexibility, transparency and opacity, or conductivity and insulation can be crucial to the functionality of the final product.

AI and Machine Learning Optimization

Artificial intelligence (AI) and machine learning algorithms will play a larger role in optimizing multicolor 3D printing processes, from design and material selection to print settings and post-processing. By analyzing vast amounts of data, these technologies can identify patterns and optimizations that would be impractical for humans to discern, leading to improvements in efficiency, quality, and material usage.

Greater Accessibility and User-Friendliness

As the technology matures, multicolor 3D printers will become more accessible to a wider audience, including hobbyists, educators, and small businesses. User-friendly design software, intuitive printer interfaces, and online communities will lower the barriers to entry, enabling more people to explore the creative and practical applications of multicolor printing.

Sustainability Focus

Sustainability will become a more prominent consideration in the development of multicolor 3D printing technologies. Advances may include the use of eco-friendly materials, energy-efficient printing processes, and designs that minimize waste. The ability to print objects with multiple materials in a single run can also contribute to reduced material consumption and waste.

Customization and Personalization at Scale

Multicolor 3D printing will further empower mass customization, allowing manufacturers to produce goods that are tailored to individual preferences at scale. This capability will transform industries ranging from consumer products and fashion to healthcare, where personalized solutions can provide superior outcomes and experiences.

The future of multicolor 3D printing is not just about technological advancements but about reimagining the boundaries of creativity, innovation, and personalized production. As these technologies continue to evolve, they will unlock new possibilities for creators, innovators, and businesses, heralding a new era of manufacturing that is more dynamic, expressive, and tailored to individual needs and aspirations.

Conclusion

The journey through the world of multicolor 3D printing reveals a technology brimming with potential, not just for revolutionizing manufacturing and prototyping, but for opening up new vistas of creativity and personal expression. From its humble beginnings to the advanced capabilities we see today, multicolor printing has transcended mere novelty to become a pivotal tool in numerous fields, heralding a future where the limitations of fabrication are bound only by our imagination.

Transforming Industries

In healthcare, education, consumer goods, and art, multicolor 3D printing is not merely enhancing existing processes; it’s redefining what’s possible. It enables the creation of intricate, customized, and functional objects that blend aesthetics with utility, bringing concepts to life in a way that was previously unimaginable. This technology is transforming the landscape of manufacturing, shifting paradigms from mass production to mass customization, where personalization doesn’t come at a premium.

The Power of Creativity and Innovation

Multicolor 3D printing stands as a testament to human creativity and the relentless pursuit of innovation. By allowing designers, engineers, and artists to merge multiple materials and colors in a single print, it has opened up a world where functional objects can be as expressive as works of art, and educational models can be as compelling as the concepts they represent. This fusion of form and function is not just enhancing the aesthetic appeal of 3D printed objects; it’s expanding the horizons of what can be achieved through additive manufacturing.

Facing Challenges Head-On

Despite the promise, the path forward for multicolor 3D printing involves navigating technical challenges, from achieving precise color accuracy and material compatibility to simplifying the design process. Yet, the solutions to these challenges are being pursued with vigor, driven by innovations in printer technology, materials science, and software development. As these solutions emerge, they promise to make multicolor printing even more accessible, efficient, and versatile.

Looking to the Future

The future of multicolor 3D printing shines brightly on the horizon, illuminated by ongoing advancements in technology and a growing recognition of its potential. As we look ahead, we can anticipate a world where multicolor printers are as commonplace as their monochromatic predecessors, enabling not just professionals but hobbyists and educators to bring their visions to vibrant reality. This future is not just about the objects we can create but about the barriers we can break down in the process of creation, making it an exciting time for anyone involved in the field of 3D printing.

A Canvas for the Imagination

In essence, multicolor 3D printing represents a canvas for the imagination, offering an unprecedented blend of creativity and functionality. As this technology continues to evolve, it will undoubtedly play a pivotal role in shaping the future of design, manufacturing, and personal expression. The journey of multicolor 3D printing is just beginning, and it promises to be as colorful and diverse as the prints it produces.

In conclusion, 3D printed multicolor is not just an advancement in printing technology; it’s a revolution in how we think about making and interacting with the world around us. It challenges us to dream bigger, design smarter, and appreciate the beauty in functionality. The future is multicolor, and it’s unfolding one layer at a time.

FAQs

- What is multicolor 3D printing?

Multicolor 3D printing is the process of creating objects with multiple colors and materials in a single print, enhancing both aesthetic appeal and functionality. - Can any 3D printer print in multicolor?

Not all 3D printers are capable of multicolor printing. It requires specific technology, such as printers with multiple extruders or specialized color blending capabilities. - What materials can be used for multicolor printing?

While plastics are most common, advancements are being made to incorporate a wider range of materials, including resins and metals, for multicolor printing. - How do I prepare my design for multicolor printing?

Preparing a design for multicolor printing involves using compatible software to define color regions and ensuring your design is segmented appropriately for your printer’s capabilities. - What are the main benefits of multicolor 3D printing?

The main benefits include the ability to create more realistic prototypes, personalized objects, and products that are both functional and aesthetically pleasing, without the need for post-processing painting or assembly.