Choosing the Best Resin 3D Printer: A Buyer’s Guide for 2024

Are you excited about diving into the world of resin 3D printing in 2024 but feeling a bit overwhelmed by the choices? You’re not alone! With advancements in technology, the variety of resin 3D printers available today can make picking the right one a daunting task. But don’t worry; you’ve come to the right place.

In this guide, we’ll break down everything you need to know to find the perfect resin 3D printer that fits your needs and budget. From understanding what makes resin printers unique to exploring the top models on the market, we’ll cover all the essentials. Whether you’re a hobbyist looking to create intricate models or a professional in need of high-precision prints, we’ll help you navigate through your options and make an informed decision. So, sit back, relax, and let’s unravel the mystery of choosing the best resin 3D printer for 2024!

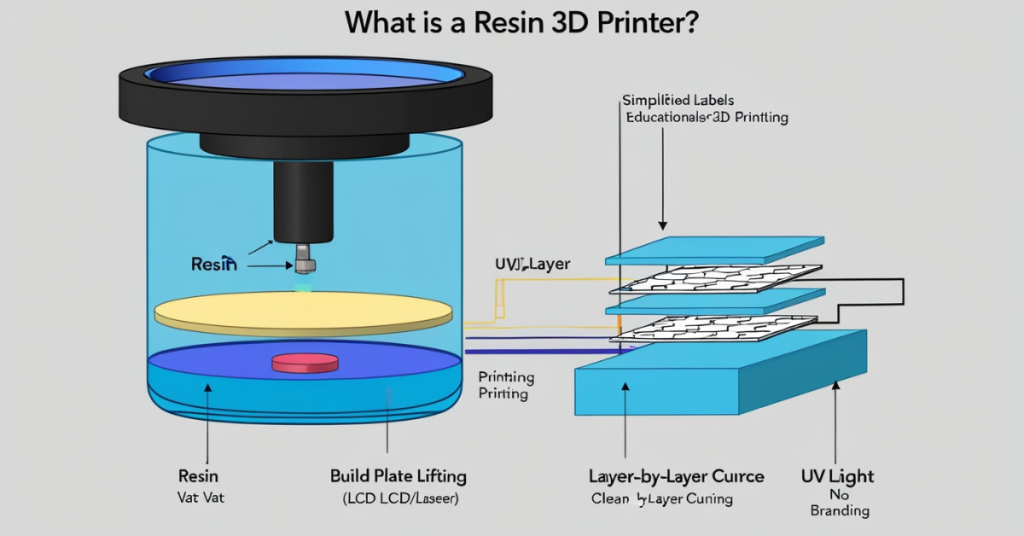

What is a Resin 3D Printer?

If you’ve been exploring the realm of 3D printing, you might have come across resin 3D printers. But what exactly are they, and how do they differ from traditional 3D printers? Let’s dive into it.

A resin 3D printer is a type of 3D printer that uses liquid resin, which is a photosensitive material, to create highly detailed and precise objects. Unlike filament-based 3D printers, which extrude plastic filament to build up layers, resin printers use a different approach. They rely on ultraviolet (UV) light to cure or harden the liquid resin layer by layer.

Here’s a breakdown of how resin 3D printers work:

- Liquid Resin: Resin printers use a tank filled with liquid photopolymer resin. This resin remains in a liquid state until exposed to UV light.

- Layer-by-Layer Printing: The printer’s build platform moves into the resin tank, and a UV light source (like an LCD screen or a laser) shines on specific areas of the resin. This light solidifies the resin in those areas, forming the first layer of the print.

- Curing and Solidification: Once a layer is cured, the build platform moves up slightly, and the printer adds the next layer of resin. This process repeats until the entire model is completed.

- Post-Processing: After printing, the object typically requires additional curing to fully harden and achieve the desired strength. This is often done in a UV curing chamber.

The result? High-resolution prints with incredibly fine details and smooth surfaces. Resin printers excel at creating intricate designs like miniatures, jewelry, and detailed prototypes. They’re perfect for projects where precision and quality are paramount.

So, if you’re after prints with extraordinary detail and a superior finish, a resin 3D printer might just be your new best friend!

Why Choose a Resin 3D Printer?

So, why should you consider investing in a resin 3D printer over other types? Let’s explore some compelling reasons that make resin printers a standout choice for many users.

High Resolution Prints

One of the biggest advantages of resin 3D printers is their ability to produce exceptionally high-resolution prints. If you’ve ever marveled at the fine details of a miniature figure or the intricate designs of custom jewelry, you can thank resin printing technology for that. Resin printers can achieve incredibly precise layers, capturing even the smallest nuances in your designs. This makes them ideal for projects where every detail counts.

Superior Surface Finish

Say goodbye to the noticeable layer lines and rough textures often seen in filament-based prints. Resin printers provide a smooth, almost polished finish straight off the printer. This is particularly beneficial for items that require minimal post-processing, such as prototypes, figurines, and decorative pieces. The smooth surface finish not only enhances the appearance of your prints but also reduces the time and effort needed for additional finishing work.

Better Accuracy and Detail

Resin 3D printers shine when it comes to accuracy and detail. The ability to print at finer resolutions means that even the most complex geometries and tiny features can be reproduced with precision. This is crucial for applications like dental models, engineering prototypes, and highly detailed art pieces. The accuracy of resin printing ensures that your creations match your specifications exactly.

Versatility in Resin Types

Modern resin printers offer a range of resin types, each designed for different purposes. From standard resins to those that are flexible, durable, or castable, you can choose the resin that best fits your project’s needs. This versatility opens up possibilities for various applications, allowing you to experiment and find the best material for your specific use case.

Faster Printing Times for Small Objects

For smaller objects, resin printers can often produce prints more quickly compared to their filament counterparts. This is due to the way resin printing layers are cured, which can be faster than the extrusion and cooling processes of filament printers. If you’re working on small, intricate items and need quick turnaround times, a resin printer might be the way to go.

Minimal Waste

Resin printing tends to produce less waste compared to filament-based methods. The resin is used only where it’s needed, and any unused resin can often be returned to the tank for future prints. This efficiency can be a significant advantage for both environmental concerns and cost savings.

In summary, choosing a resin 3D printer can offer you unparalleled detail, smooth finishes, and a range of resin options suited to various needs. Whether you’re a hobbyist, artist, or professional, the precision and quality provided by resin printers can elevate your projects and bring your creative visions to life.

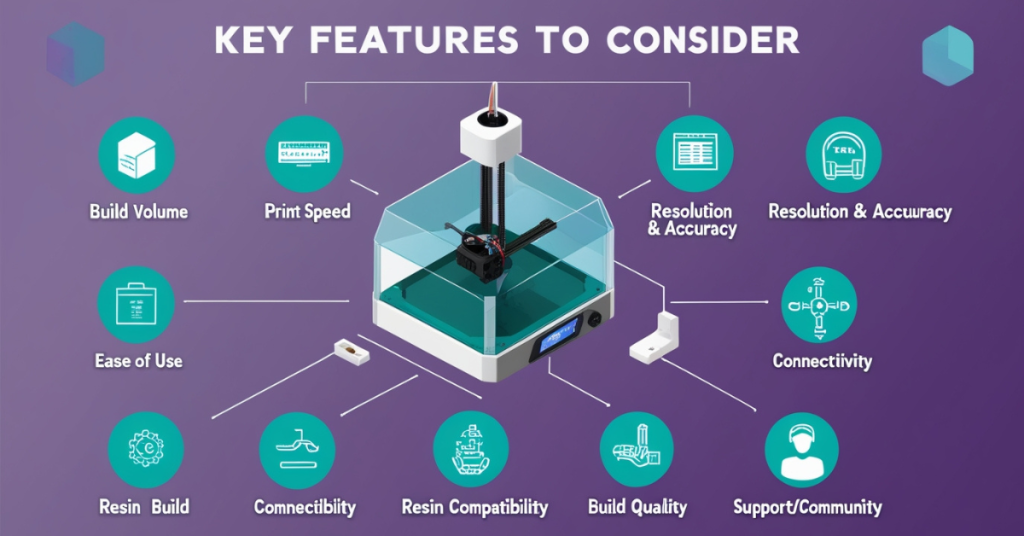

Key Features to Consider

When choosing a resin 3D printer, there are several crucial features to evaluate to ensure you pick the right one for your needs. Here’s a detailed look at what to consider:

Build Volume

The build volume of a resin printer refers to the maximum size of the object you can print. It’s measured in width, depth, and height. If you’re planning to create larger models or multiple smaller items in one go, you’ll need a printer with a larger build volume. On the other hand, if your projects are typically small and intricate, a printer with a more compact build volume might suffice. Consider your typical print sizes and make sure the printer’s build volume aligns with your requirements.

Print Speed

Print speed is another important factor. While resin printers can offer high-resolution prints, the speed at which they complete a print can vary. Faster print speeds can be beneficial if you have tight deadlines or if you frequently produce prototypes. However, be cautious: very fast print speeds might sometimes compromise the quality of the final output. Look for a balance between speed and the level of detail you need.

Resolution and Accuracy

Resolution and accuracy are critical in resin printing. Resolution is usually described in microns and affects the detail level of your prints. Higher resolution means finer details. Accuracy relates to how precisely the printer can reproduce your digital model. If your projects demand intricate details and exact replicas, choose a printer known for its high resolution and accuracy. Check the specifications and user reviews to ensure the printer meets your expectations for detail and precision.

Ease of Use

A user-friendly interface can make a big difference in your 3D printing experience. Look for features that simplify the setup, operation, and maintenance of the printer. This might include an intuitive touchscreen interface, easy-to-navigate software, and straightforward calibration processes. Additionally, some printers come with automatic leveling or resin dispensing systems, which can significantly ease the setup and operation for beginners.

Connectivity Options

Connectivity options determine how you transfer files to your printer and how it integrates with your workflow. Common options include USB, SD card, Wi-Fi, and Ethernet. Depending on your setup, you might prefer a printer that supports wireless connections for convenience or one that uses physical media for security. Evaluate the connectivity options and ensure they fit seamlessly into your existing processes.

Resin Compatibility

Different resin printers are compatible with different types of resin. Make sure the printer you choose supports the type of resin you plan to use. Some printers offer a wider range of resin compatibility, including standard, flexible, durable, and castable resins. This versatility can be advantageous if you want to experiment with different materials for various applications.

Build Quality and Durability

A printer’s build quality impacts its longevity and performance. Look for robust construction and high-quality materials that ensure the printer can withstand regular use. Check for reviews and manufacturer information regarding the durability of the printer. A well-built printer will offer better stability and consistent print quality over time.

Support and Community

Finally, consider the support and community surrounding the printer. A strong user community and good customer support can be invaluable when troubleshooting issues or seeking advice. Check if the manufacturer offers comprehensive support, such as detailed documentation, troubleshooting guides, and responsive customer service. Additionally, an active online community can provide tips, troubleshooting help, and creative ideas.

In summary, evaluating these key features will help you find a resin 3D printer that meets your needs and enhances your printing experience. From build volume and print speed to ease of use and resin compatibility, taking the time to consider these factors will lead you to a printer that aligns perfectly with your projects.

Top Resin 3D Printers of 2024

When it comes to choosing the best resin 3D printer for 2024, there are several standout models that cater to different needs, from hobbyists to professionals. Here’s a curated list of top resin 3D printers this year:

- Anycubic Photon Mono X

Pros:

• High Resolution: 4K monochrome screen for sharp details and smooth surfaces.

• Large Build Volume: 300 x 298 x 164 mm, allowing for larger prints or multiple items at once.

• Fast Printing Speed: Monochrome screen technology significantly speeds up print times.

Cons:

• Noise Levels: Can be somewhat noisy during operation.

Size: Larger footprint might require a dedicated workspace.

(See – For Prices)

Overview: The Anycubic Photon Mono X is known for its impressive print quality and fast curing times, making it a popular choice for both enthusiasts and professionals who need large prints and high detail.

- Elegoo Mars 3

Pros:

• Excellent Detail: 4K monochrome LCD for high precision.

• User-Friendly: Intuitive touchscreen interface and easy setup.

• Affordable: Great value for the price, making it accessible for beginners.

Cons:

• Build Volume: Smaller compared to other models, measuring 143 x 89 x 175 mm.

• Print Speed: Slower compared to some higher-end models.

(See – For Prices)

Overview: The Elegoo Mars 3 offers excellent print quality at a reasonable price, ideal for those who are new to resin printing or need a reliable printer for smaller projects.

- Prusa SL1S Speed

Pros:

• Ultra-Fast Printing: Notable for its speed, thanks to its innovative LFS (Liquid Crystal Display) technology.

• High Accuracy: Excellent resolution and consistent print quality.

• Solid Build: Sturdy construction and reliable performance.

Cons:

• Cost: Higher price point compared to other resin printers.

• Learning Curve: Slightly more complex setup and operation.

(See – For Prices)

Overview: The Prusa SL1S Speed is a top choice for those who need speed without sacrificing quality. Its advanced features and robust build make it a go-to for professionals looking for high-performance resin printing.

- Anycubic Photon Mono 4K

Pros:

• High Resolution: 4K monochrome screen delivers detailed and accurate prints.

• Affordable: Good balance of features and price.

• Compact Size: Fits well in smaller workspaces.

Cons:

• Build Volume: Smaller build volume compared to other models, measuring 218 x 123 x 235 mm.

• Limited Connectivity: Lacks advanced connectivity options.

(See – For Prices)

Overview: The Anycubic Photon Mono 4K is known for its affordability and excellent print quality, making it a great option for hobbyists and those on a budget.

- Phrozen Sonic Mega 8K

Pros:

• Super High Resolution: 8K monochrome screen for incredible detail.

• Large Build Volume: 218 x 123 x 235 mm, accommodating larger prints.

• Fast Printing Speed: Designed for quick and efficient printing.

Cons:

• Price: On the higher end, which might be a consideration for budget-conscious buyers.

• Size: Larger footprint requires more space.

(See – For Prices)

Overview: The Phrozen Sonic Mega 8K stands out with its ultra-high resolution and large build volume, making it suitable for professionals and those who need top-tier detail and size capabilities.

Comparing the Best Models

When selecting a resin 3D printer, understanding the differences between top models can help you make an informed decision. Here’s a comparison of the leading resin printers in 2024 based on several key criteria:

Print Quality and Resolution

- Anycubic Photon Mono X: Offers exceptional print quality with a 4K monochrome screen, providing sharp details and smooth finishes. Its large build volume complements its high resolution, making it ideal for both detailed small prints and larger objects.

- Elegoo Mars 3: Known for its 4K monochrome LCD, it delivers high-resolution prints with fine details. While its build volume is smaller, the print quality remains excellent, making it a great choice for detailed work on a budget.

- Prusa SL1S Speed: Features ultra-high resolution with LFS technology, providing outstanding detail and precision. It excels in producing fine details quickly but comes at a higher price point.

- Anycubic Photon Mono 4K: This model also offers a 4K monochrome screen for detailed prints. Its resolution and print quality are impressive, although its build volume is smaller compared to others.

- Phrozen Sonic Mega 8K: Stands out with its 8K monochrome screen, offering the highest resolution among these models. Its large build volume allows for big, detailed prints, though it’s on the pricier side.

Build Volume

- Anycubic Photon Mono X: Features a large build volume of 300 x 298 x 164 mm, allowing for bigger prints or multiple items at once. This is ideal for users needing more space for larger projects.

- Elegoo Mars 3: Smaller build volume of 143 x 89 x 175 mm, which might limit the size of individual prints but is sufficient for smaller, intricate objects.

- Prusa SL1S Speed: Offers a moderate build volume, balancing between compact size and usability. Its build area suits most professional applications without being excessively large.

- Anycubic Photon Mono 4K: Provides a build volume of 218 x 123 x 235 mm, fitting well for medium-sized prints. It’s a good compromise between size and resolution.

- Phrozen Sonic Mega 8K: Boasts a large build volume of 218 x 123 x 235 mm, similar to the Anycubic Photon Mono 4K, but with a higher resolution. This makes it versatile for both large and detailed prints.

Print Speed

- Anycubic Photon Mono X: Known for its fast printing speeds due to the monochrome screen, which reduces curing times. This is a significant advantage for those needing quicker results.

- Elegoo Mars 3: While not the fastest, it provides a good balance of speed and quality. Suitable for users who prioritize detail over speed.

- Prusa SL1S Speed: Highlights its ultra-fast printing capabilities thanks to its advanced LFS technology. Ideal for professionals who need to produce high-quality prints quickly.

- Anycubic Photon Mono 4K: Offers faster print speeds compared to many competitors due to its monochrome screen, though not as fast as the Prusa SL1S Speed.

- Phrozen Sonic Mega 8K: Provides fast printing speeds, benefiting from its monochrome screen. It’s a good choice for those who need both large and detailed prints without lengthy wait times.

Ease of Use

- Anycubic Photon Mono X: Comes with a user-friendly interface and features like automatic leveling, making it accessible for users of all skill levels.

- Elegoo Mars 3: Offers an intuitive touchscreen and straightforward setup, which is great for beginners. It also has a robust online community for support.

- Prusa SL1S Speed: While highly capable, it has a steeper learning curve due to its advanced features. However, it provides comprehensive support and documentation.

- Anycubic Photon Mono 4K: User-friendly with an easy-to-navigate interface and reliable performance, though it may lack some of the advanced features found in higher-end models.

- Phrozen Sonic Mega 8K: Provides a good balance of user-friendliness and advanced features, but its larger size may require more space and setup consideration.

Price and Value

- Anycubic Photon Mono X: Higher-priced but offers significant value with its large build volume and fast printing capabilities. Great for those needing a high-performing printer.

- Elegoo Mars 3: Affordable and offers excellent value for its price, making it a popular choice for budget-conscious users who don’t want to compromise on print quality.

- Prusa SL1S Speed: Premium price reflecting its top-notch performance and speed. Best for professionals who need high efficiency and are willing to invest in advanced features.

- Anycubic Photon Mono 4K: Mid-range pricing with solid features and print quality, offering good value for users who need a reliable printer without breaking the bank.

- Phrozen Sonic Mega 8K: On the higher end of the price spectrum, but the 8K resolution and large build volume provide excellent value for those needing top-tier detail and size.

This comparison highlights the strengths and considerations of each model, helping you choose the best resin 3D printer based on your specific needs, whether it’s high resolution, build volume, speed, ease of use, or budget.

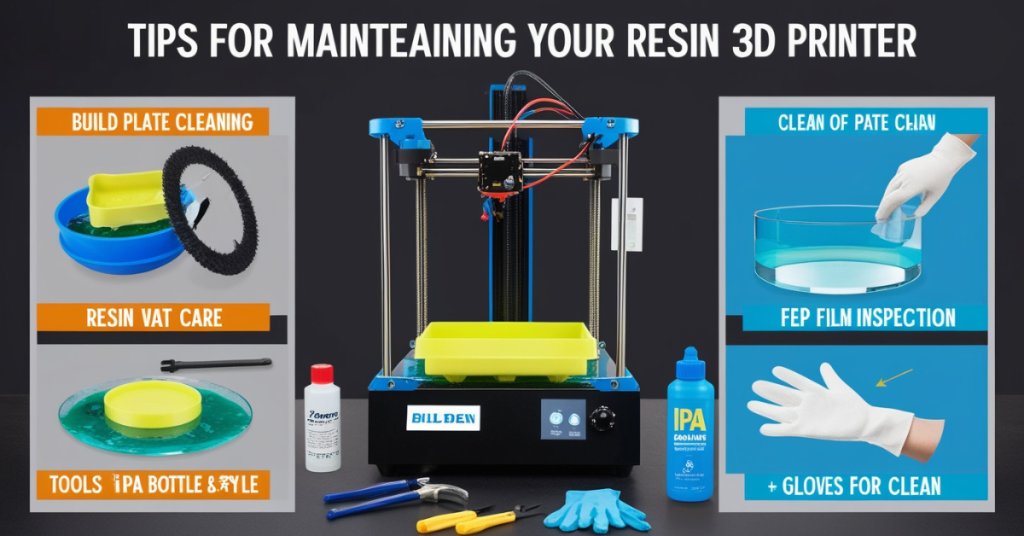

Tips for Maintaining Your Resin 3D Printer

Proper maintenance of your resin 3D printer is essential to ensure its longevity and optimal performance. Regular upkeep can prevent issues, enhance print quality, and save you from costly repairs. Here are some comprehensive tips to keep your resin printer in top shape:

- Regularly Check and Replace the FEP Film

What is FEP Film? The FEP (fluorinated ethylene propylene) film is a transparent layer that sits at the bottom of the resin vat and helps to separate the print from the vat.

Maintenance Tip: Inspect the FEP film regularly for any signs of wear or damage, such as scratches, bubbles, or tears. Replace the film if it shows significant wear or if it starts affecting print quality. A damaged FEP film can cause adhesion issues and impact the accuracy of your prints.

- Clean the Build Plate After Each Print

Why Clean? Residual resin on the build plate can affect the adhesion of future prints and lead to uneven surfaces.

Maintenance Tip: After each print, clean the build plate with isopropyl alcohol (IPA) or a similar cleaning solution. Use a soft brush or cloth to gently remove any leftover resin or debris. Ensuring the build plate is clean helps maintain good adhesion and prevents print failures.

- Maintain the Resin Vat

Why Vat Maintenance Matters: The resin vat holds the liquid resin and its condition affects print quality. Residual resin and debris can lead to print defects.

Maintenance Tip: Regularly clean the resin vat with IPA. Be cautious not to damage the FEP film. If your resin vat has a removable liner, clean it thoroughly after each use. Additionally, ensure there is no resin build-up on the vat’s edges or in the corners.

- Keep the Printer and Work Area Clean

Why Cleanliness is Crucial: A clean work area helps prevent contamination of the resin and ensures that your printer operates smoothly.

Maintenance Tip: Regularly wipe down the exterior of the printer with a damp cloth. Avoid getting any liquid inside the printer. Keep the work area free of dust and debris. Also, ensure proper ventilation to avoid the build-up of resin fumes, which can be harmful.

- Check and Calibrate the Printer Regularly

Why Calibration Matters: Proper calibration ensures that the printer performs accurately and produces high-quality prints.

Maintenance Tip: Perform routine calibration checks as recommended by the manufacturer. This includes checking the leveling of the build plate and ensuring that the printer’s axes are correctly aligned. Regular calibration helps prevent print misalignment and improves overall print quality.

- Store Resin Properly

Why Proper Storage is Important: Resin can degrade over time, especially when exposed to light and heat, affecting its performance.

Maintenance Tip: Store resin in a cool, dark place to prevent it from curing prematurely. Use opaque containers to protect the resin from UV light. Ensure the containers are tightly sealed to avoid contamination and evaporation.

- Replace Worn-Out Parts Promptly

Why Timely Replacement Matters: Worn-out parts can lead to decreased performance and potential damage to the printer.

Maintenance Tip: Regularly inspect components such as the LCD screen, UV light source, and mechanical parts for signs of wear. Replace any parts that are damaged or show signs of deterioration. Keeping spare parts on hand can minimize downtime and ensure uninterrupted printing.

- Perform Firmware Updates

Why Updates are Necessary: Firmware updates can improve printer functionality and fix bugs.

Maintenance Tip: Check the manufacturer’s website or user forums for any available firmware updates for your printer. Follow the update instructions carefully to ensure a smooth installation. Regular updates can enhance the printer’s performance and introduce new features.

- Use Proper Safety Gear

Why Safety Gear is Important: Resin can be hazardous if not handled properly.

Maintenance Tip: Always wear gloves and safety glasses when handling resin. Ensure proper ventilation in your workspace to avoid inhaling fumes. Clean up any spills immediately to prevent accidents and maintain a safe working environment.

- Keep a Maintenance Log

Why a Log Helps: Keeping track of maintenance activities can help you stay organized and spot recurring issues.

Maintenance Tip: Maintain a log of all maintenance activities, including cleaning, part replacements, and calibration checks. Note any issues encountered and how they were resolved. This log can be valuable for troubleshooting and ensuring consistent maintenance.

By following these maintenance tips, you can keep your resin 3D printer in excellent condition, ensuring it continues to produce high-quality prints and operates efficiently. Regular upkeep not only extends the lifespan of your printer but also helps avoid common issues that can disrupt your printing projects.

Conclusion

Choosing the right resin 3D printer for your needs in 2024 is an exciting endeavor that can open doors to endless creative possibilities. With advancements in technology, today’s resin printers offer exceptional detail, speed, and versatility, making them ideal for both hobbyists and professionals.

When selecting a resin 3D printer, consider factors such as print quality, build volume, speed, ease of use, and budget. Each model on our list brings unique strengths to the table—whether it’s the ultra-high resolution of the Phrozen Sonic Mega 8K or the affordability and reliability of the Elegoo Mars 3. By evaluating these aspects, you can find the printer that best aligns with your specific requirements.

Remember, proper maintenance is key to ensuring the longevity and optimal performance of your printer. Regular cleaning, calibration, and careful handling of resin will keep your machine running smoothly and help you achieve consistent, high-quality prints.

Ultimately, the best resin 3D printer for you is one that matches your needs and budget while offering the reliability and features that align with your printing goals. With the right choice, you’ll be well-equipped to embark on a journey of creativity and innovation, turning your digital designs into tangible, intricate works of art.

As you explore the world of resin 3D printing, stay informed about the latest advancements and best practices. Engaging with the 3D printing community can also provide valuable insights and support. Happy printing!

FAQs

- What is the main advantage of a resin 3D printer over a filament printer?

Resin 3D printers offer higher resolution and better surface finish compared to filament printers, making them ideal for detailed and intricate prints. - How often should I clean my resin 3D printer?

It’s best to clean your printer after every few prints or whenever you notice a decline in print quality. Regular cleaning prevents resin buildup and ensures consistent performance. - Can I use any type of resin with my printer?

No, you should use resins that are compatible with your printer’s specifications. Check the manufacturer’s recommendations for the best results. - What is the average lifespan of a resin 3D printer?

With proper maintenance, a resin 3D printer can last several years. Regular cleaning and proper storage help extend its lifespan. - Are there any safety precautions I should take when using a resin 3D printer?

Yes, always use resin in a well-ventilated area and wear gloves when handling resin to avoid skin irritation. Follow the manufacturer’s safety guidelines for best practices.